-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Forging Rods Gr.2 ASTM B348 ASTM F67 Artificial Skeleton

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTM B348 |

| Minimum Order Quantity | 50kg |

| Price | $35.00 - $125.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Grade | Grade 2 | Technology | Hot Forging Hot Rolled Machining |

|---|---|---|---|

| Production Standards | ASTM B348, ASME SB348, ASTM F136 | Heat Resistance | High |

| Processing Equipment | CNC Lathe, Milling Machine | Key Words | Ti6242 Titanium Round Bar |

| Standard | GJB2744 | Supply State | Annealed |

| Corrosion Resistance | High | Item | 3.7165 Round Bar In Titanium Grade 5 |

| Density | 4.51 G/cm3 | Surface Finish | Polished |

| Finish | Polished | Diameter | ¢40---150mm |

| Highlight | Gr.2 Titanium Forging Rods,Titanium forging rods Artificial Skeleton,ASTM B348 Titanium forging rods |

||

Description

Titanium alloy rods are slender structural components made from titanium alloy, often used in construction engineering, interior decoration, and industrial applications.

They are known for being lightweight, strong, and visually appealing, with excellent corrosion resistance and high mechanical strength.

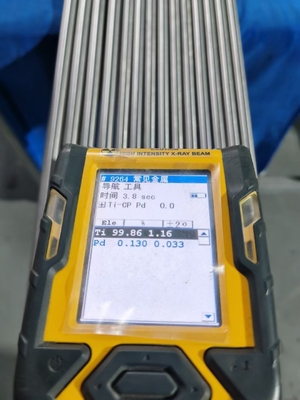

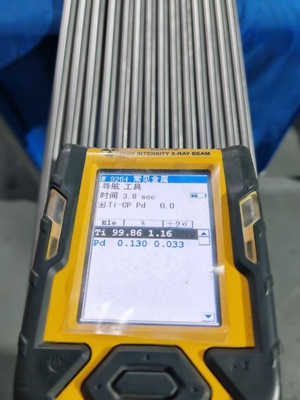

Titanium Gr17 alloy rod, in particular, is a palladium-stabilized titanium alloy that offers exceptional performance in corrosive environments, especially in reducing acids such as dilute hydrochloric, sulfuric, and phosphoric acids.

Specifications

| Product Name | Titanium Gr17 Alloy Rod |

|---|---|

| Chemical Composition | Ti–0.05Pd |

| Palladium Content | 0.04% ≤ Pd ≤ 0.08% |

| Density | 4.51 g/cm³ |

| Standard | ASTM B348 |

| Advantages | High melting point, non-magnetic, low coefficient of thermal expansion |

| Applications | Suitable for dilute hydrochloric acid, dilute sulfuric acid, and dilute phosphoric acid environments |

Stock Availability

| Size | A/F 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 35mm, 40mm (custom sizes available) |

|---|---|

| Grades | Gr1, Gr2, Gr5, Gr7, Gr9, Gr12, Gr23 |

| Length | 1000–6000 mm |

| Standards | ASTM B348, ASTM B381 |

| Surface Finish | Polished, Pickled Surface (Titanium Hex Bar per ASTM B348) |

Physical Properties and Composition

| Property | Value |

|---|---|

| Density | 4.51 g/cm³ |

| Melting Point | ~1660°C |

| Tensile Strength | ≥ 485 MPa |

| Yield Strength | ≥ 345 MPa |

| Elongation | ≥ 20% |

| Hardness | ≤ 200 HB |

| Modulus of Elasticity | 105 GPa |

Applications

The Gr17 Titanium Alloy Rod is widely used across industrial, medical, chemical, and marine sectors due to its combination of mechanical strength, heat resistance, and excellent corrosion resistance.

1. Aerospace Industry

Gr17 titanium rods are used in aircraft engine compressor parts, rockets, missiles, and high-speed aircraft structures due to their lightweight and high-strength properties.

2. Medical Field

With excellent biocompatibility, Gr17 titanium is used for medical implants, orthopedic rods, and dental components, minimizing human tissue rejection.

3. Chemical and Marine Engineering

Outstanding corrosion resistance makes it ideal for equipment exposed to seawater or acidic environments — such as chemical containers, pipelines, and marine structural parts.

4. Power Generation Industry

Used for electrodes in electrolytic cells, power station condensers, and heaters in petroleum refining and seawater desalination plants.

5. Environmental Protection and Advanced Materials

Applied in the production of hydrogen storage materials, shape memory alloys, and energy-efficient components, contributing to sustainability and energy conservation technologies.