-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

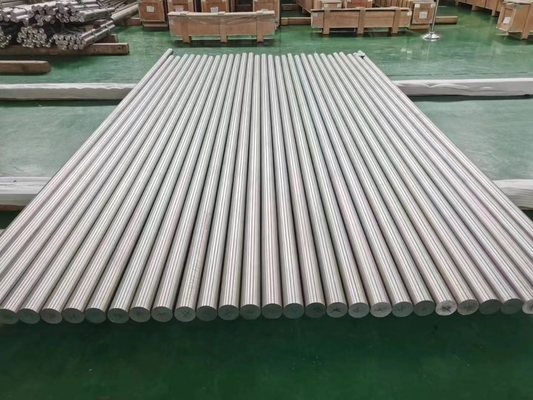

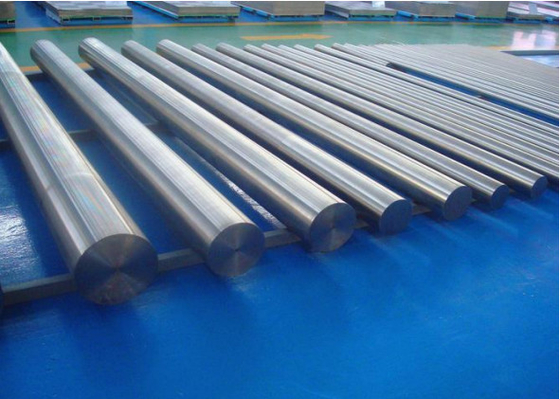

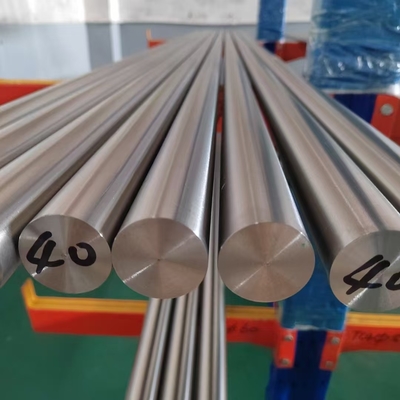

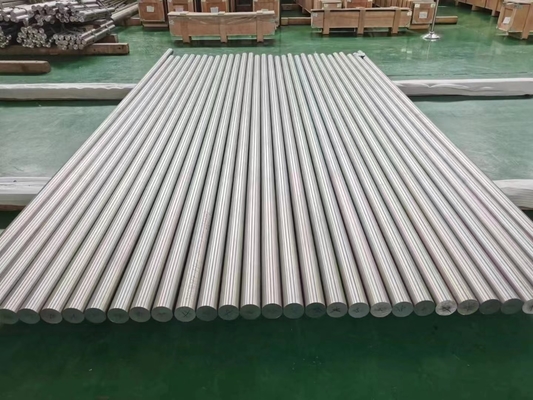

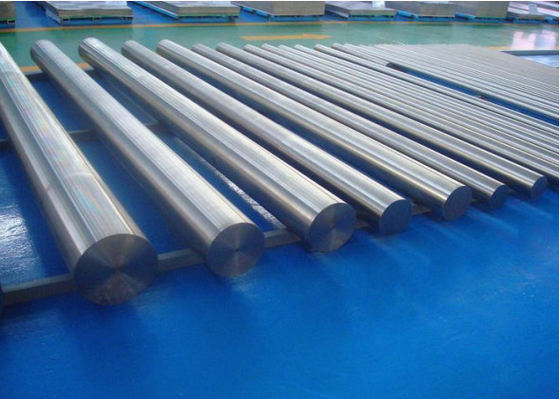

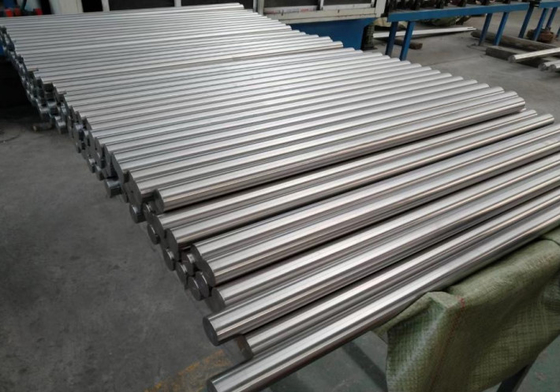

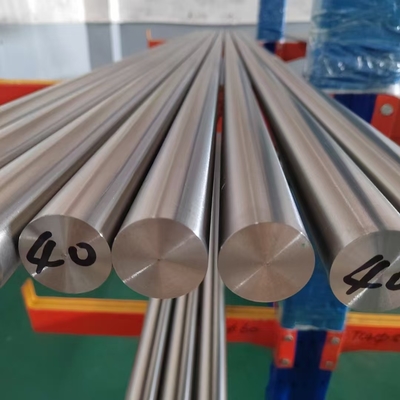

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Round Bar Forgings Rolling Polished ASTM B348 ASTM F136 Annealed with 4.51 g/cm3 Density and Customizable Length

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTM B348、ASTM F136 |

| Minimum Order Quantity | 50kg |

| Price | $35.00 - $125.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Purity | ≥99.7% | Surface Finish | Polished |

|---|---|---|---|

| Length | Customizable | Yield | 625MPA |

| Color | Sliver | Density | 4.51 G/cm3 |

| Elongation | 24% | Advantage | Large Stock, Short Lead Time |

| Shape | Round | Diameter Tolerance | H7, H8, H9 |

| Available Forms | Round Bar, Square Bar, Hexagonal Bar | Standard | ASTM B348 |

| Chemical Composition | Typically >99% Titanium | Processing Equipment | CNC Lathe, Hydraulic Press, Rolling Mill |

| Heat Treatment | Annealing At 700-785°C | ||

| Highlight | Rolling Polished Titanium Round Bar,Annealed Titanium Round Bar,ASTM B348 Titanium Round Bar |

||

Description

Gr.17 titanium alloy rod is a slender, high-performance component made of titanium–palladium alloy (Ti–0.05Pd).

It is characterized by lightweight, high strength, attractive appearance, and excellent corrosion resistance.

This titanium alloy can be easily machined or processed for use in construction engineering, industrial manufacturing, and precision applications.

Due to the addition of palladium, Gr.17 titanium exhibits superior resistance to reducing acids, making it ideal for chemical, marine, and medical environments.

Specifications

| Product Name | Titanium Gr.17 Alloy Rod |

|---|---|

| Material | Ti–0.05Pd |

| Palladium Content | 0.04% ≤ Pd ≤ 0.08% |

| Density | 4.51 g/cm³ |

| Standard | ASTM B348 |

| Advantages | High melting point, non-magnetic, low coefficient of thermal expansion |

| Application Environment | Dilute hydrochloric acid, dilute sulfuric acid, dilute phosphoric acid |

Stock Availability

Size (Across Flats): 10 mm, 12 mm, 14 mm, 16 mm, 18 mm, 20 mm, 25 mm, 30 mm, 35 mm, 40 mm

(Custom sizes available on request)

Grades Available: Gr1, Gr2, Gr5, Gr7, Gr9, Gr12, Gr23

Length: 1000–6000 mm

Standards: ASTM B348, ASTM B381

Surface Finish: Polished / Pickled

Chemical Composition (Typical)

| Element | N (max) | C (max) | H (max) | Fe (max) | O (max) | Pd | Ti |

|---|---|---|---|---|---|---|---|

| Gr.17 (Ti–0.05Pd) | 0.03 | 0.08 | 0.015 | 0.25 | 0.25 | 0.04–0.08 | Balance |

Applications

1. Aerospace

Gr.17 titanium rods are widely used in aircraft engine compressor parts, rockets, missiles, and high-speed aircraft structures, due to their excellent strength-to-weight ratio and high temperature stability.

2. Medical Field

The biocompatibility of Gr.17 titanium makes it ideal for orthopedic implants, dental implants, and medical devices, helping reduce body rejection and ensuring long-term safety.

3. Chemical and Marine Engineering

Exceptional corrosion resistance in acidic and marine environments makes Gr.17 suitable for chemical pipelines, reaction vessels, heat exchangers, and marine structural components.

4. Electric Power Industry

Used for electrodes, power station condensers, petroleum heaters, and seawater desalination systems, demonstrating excellent performance under high temperature and corrosive conditions.

5. Environmental Protection and Energy

Applied in hydrogen storage materials and shape memory alloys, contributing to energy-saving and green technology development.

Advantages

Excellent corrosion resistance in both oxidizing and reducing media

Superior strength-to-weight ratio

Outstanding biocompatibility for medical use

High temperature stability and durability

Non-magnetic and low thermal expansion

Long service life and minimal maintenance