-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

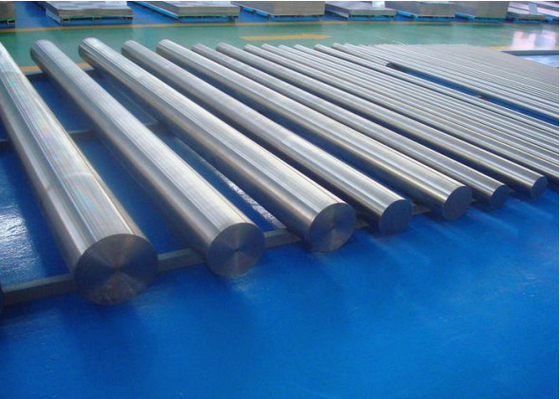

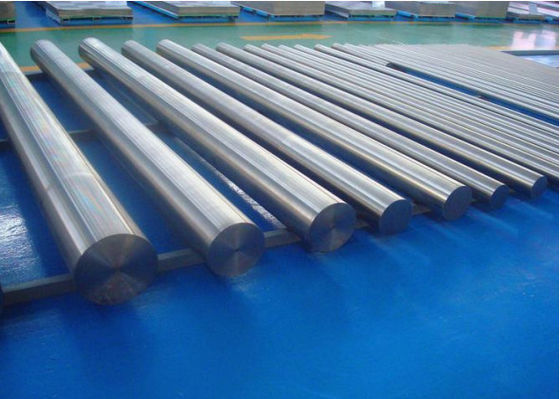

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Dimention | As Order | Supply Status | R Y M |

|---|---|---|---|

| Purity | ≥99.7% | Standrad | ASTM B348,ASTM F136,ASTM F67 |

| Elongation | 24% | Tolerance | Tolerance H7 |

| Hardness | 285-340HB | Chemical Composition | Typically >99% Titanium |

| Highlight | Low H7 Tolerance Titanium Round Bar,ASTM B348 Titanium Round Bar,24% Elongation Titanium Round Bar |

||

Product Description:

Our Titanium bar is manufactured to meet the highest industry standards, including ASTM B348, ASTM F136, and ASTM F67, ensuring that it meets all necessary quality and safety requirements. This makes it the perfect choice for use in a wide range of industries, including aerospace, automotive, medical, and many others.

One of the key features of our Titanium bar is its excellent tolerance level. Designed to meet tolerance H7, this bar offers exceptional precision and accuracy, making it ideal for use in applications where precision is critical.

In addition to its exceptional strength and durability, our Titanium bar is also designed to withstand high temperatures and extreme conditions. It is heat-treated using annealing at 700-785°C, which ensures that it maintains its strength and durability even under the most demanding conditions. This makes it an ideal choice for use in high-temperature applications, such as jet engines and other aerospace applications.

Our Titanium bar also boasts an impressive hardness rating of 285-340HB, making it one of the strongest and most durable materials available. This makes it an ideal choice for use in applications where strength and durability are critical, such as in the construction of aircraft and other heavy-duty machinery.

Overall, our Titanium bar is a top-quality material that offers exceptional strength, durability, and resistance to corrosion, making it an ideal choice for a wide range of industrial applications. With its outstanding tolerance level, heat treatment, and impressive hardness rating, it is the perfect material for use in applications where precision, strength, and durability are critical.

Features:

- Product Name: Titanium Round Bar

- Elongation: 24%

- Diameter: Customizable

- Materials: Titanium

- Supply Status: R Y M

- Hardness: 285-340HB

Looking for a high-quality, durable, and customizable Titanium bar? Look no further than our Titanium Round Bar. Made from top-grade Titanium materials, our bar boasts an elongation rate of 24% and a hardness range of 285-340HB. Plus, with customizable diameter options and supply status options of R, Y, or M, you can rest assured that our Titanium Round Bar will meet your exact specifications.

Technical Parameters:

| Titanium Round Bar | Technical Parameters |

|---|---|

| Hardness | 285-340HB |

| Production Standards | ASTM F136, ASTM F67, ISO 5832 |

| Yield Strength | 170 MPa |

| Materials | Titanium |

| Dimension | As Order |

| Technical | Forged |

| Standard | ASTM B348,ASTM F136,ASTM F67 |

| Material Element | Titanium |

| Heat Treatment | Annealing At 700-785°C |

| Elongation | 24% |

Applications:

One of the key advantages of our Titanium Round Bar is its exceptional strength and durability. With a yield strength of 170 MPa, this bar is capable of withstanding significant stress and strain without breaking or deforming. It is also highly resistant to corrosion, which makes it an ideal choice for use in harsh or corrosive environments.

Another important feature of our Titanium Round Bar is its excellent heat treatment properties. This product can be annealed at temperatures between 700-785°C, which helps to improve its overall strength and durability. This makes it an excellent choice for use in high-temperature applications, where other materials might fail or degrade over time.

Our Titanium Round Bar is also known for its exceptional chemical composition, which is typically >99% pure titanium. This ensures that the material is highly resistant to oxidation and other forms of chemical corrosion, and it also helps to improve its overall strength and durability.

Finally, our Titanium Round Bar is manufactured to a high degree of precision and accuracy, with a tolerance of H7. This ensures that the material is suitable for use in a wide range of applications and scenarios, and that it will perform reliably and consistently over time.

So whether you're looking for a reliable material for use in aerospace, automotive, marine, or industrial applications, our Titanium Round Bar is the perfect choice. With its exceptional strength, durability, and corrosion resistance, as well as its excellent heat treatment properties and precision manufacturing, this product is a versatile and reliable solution for all your industrial needs.

Customization:

- Hardness: 285-340HB

- Technical: Forged

- Yield Strength: 170 MPa

- Supply Status: R Y M

- Tolerance: Tolerance H7

Our Titanium bar is highly customizable to fit your specific needs. With our product customization services, you can have the exact specifications that you require for your project. Our Titanium bar is known for its exceptional strength and durability, making it perfect for a variety of applications. Trust us to provide you with the highest quality Titanium bar available.

Support and Services:

Our technical support and services for our Titanium Round Bar product include:

- Assistance with product selection and specification

- Expertise in material properties and characteristics

- Recommendations for machining and fabrication techniques

- Guidance on proper storage and handling of the product

- Assistance with quality control and testing procedures

- Access to technical data and product information

Our team of experts is dedicated to providing exceptional support and service to ensure the success of your project. Contact us for any further assistance or questions you may have.