-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

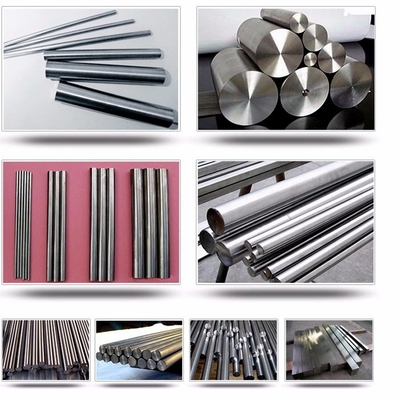

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Grade 5 Titanium Bar ASTM F136 Customized Sizes For Medical Use

| Processing Equipment | CNC Lathe, Hydraulic Press, Rolling Mill | Key Words | Titanium Metal Bar Supplier |

|---|---|---|---|

| Length | Customizable | Origin | China Valley |

| Advantage | Large Stock, Short Lead Time | Grade | Grade 5 |

| Technique | Forged, Rolled | Tolerance | According To ASTM Standards. |

| Highlight | Grade 5 Titanium Bar,ASTM F136 Titanium Bar,Customized Sizes Titanium Bar |

||

Grade 5 Titanium Bar ASTM F136 Customized Sizes For Medical Use

The standard for the titanium bar in Grade 5, which indicates that it is composed of pure titanium or titanium alloys. The diameter of the bar can be customized to meet specific requirements. The production technique used for this grade of titanium bar involves hot forging and rolling processes. These methods contribute to the strength and shape of the bar. In terms of its appearance, the color of the Grade 5 titanium bar is typically silver, which is the natural coloration of titanium when it is in its metallic form.

Product Introduction

Grade 5 Titanium Bar, due to its increased aluminum and vanadium content, represents the strongest titanium alloy available. It strikes a balance between high resistance to corrosion, weldability, and the ability to be formed into various shapes. This makes it a preferred material for critical applications such as spacer rings, fasteners, and turbine blades where strength and durability are paramount.

The selection of Grade 5 (gr5) titanium bar from Titanium Industries, as showcased below, is widely used in demanding environments across diverse sectors including oil and gas, aerospace, defense, industrial, medical, and marine industries. Its choice for these applications is driven by a unique set of properties: superior strength, lightweight nature, excellent resistance to corrosion, biocompatibility, and the capacity to perform effectively at elevated temperatures. The range of available diameters for this Grade 5 titanium bar spans from 0.125 inches (approximately 3.175 millimeters) up to 12 inches, offering versatility for a wide array of projects and specifications.

Specification

| Standard | ASTM B348, ISO 13810, ISO5832-2, ISO5832-3 ASTM F136 and ASTM F67 for medical use. |

| Grade | Grade 5 Titanium Bar |

| Diameter | 1.0-200mm Or Customized sizes |

| Length | 300mm-6000mm |

| Technique | Hot Forging & Hot Rolling |

| Surface Finish | Polishing, machining |

| Shape | Round, flat, square, hexagonal |

| Application | Industrial, Medical, Petrochemical Industry, Aerospace .etc |

| Feature | Excellent Bearing to Cryogenic property Non-magnetic and Non-toxic Good thermal properties Low modulus of elasticity |

Application

The versatility of Grade 5 titanium bar is evident in its diverse applications, which are tailored to the material's distinct properties.

In the chemical industry, the gr5 titanium bar is highly esteemed for its exceptional resistance to corrosion, making it ideal for use in environments where corrosive elements are prevalent. Its biocompatibility with human tissue also makes it a prime material for medical implants, ensuring compatibility and safety within the human body. Furthermore, its robust defense against saltwater corrosion makes it suitable for marine applications, where the harshness of the ocean environment can degrade lesser materials.

Grade 5 Titanium Bar finds extensive use in the aerospace sector due to its high strength-to-weight ratio, a critical factor in aircraft and spacecraft components where lightweight yet durable materials are essential. This same quality also makes it appealing for automotive parts and sporting equipment such as bicycle frames and golf club heads, where the balance of strength and weight is paramount.

Additionally, the material is integral in the creation of prosthetic devices, dental implants, orthopedic implants, and high-performance machinery components. Both grades of titanium are highly prized for their excellent corrosion resistance and biocompatibility, underlining their popularity in medical and chemical sectors where these qualities are imperative.