-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

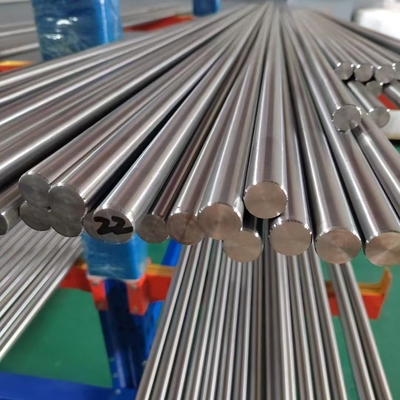

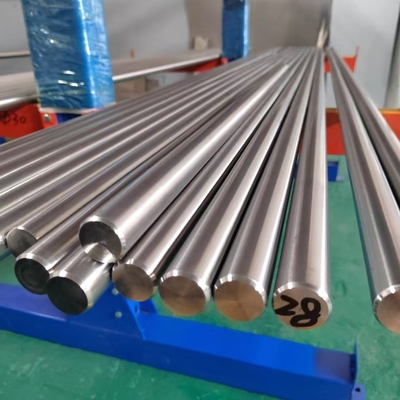

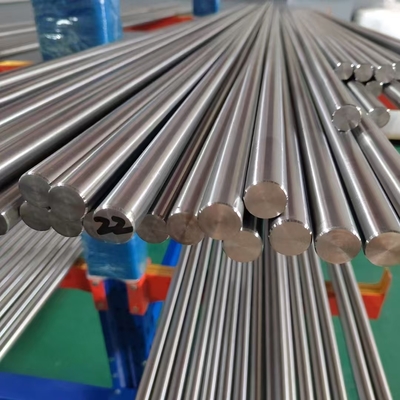

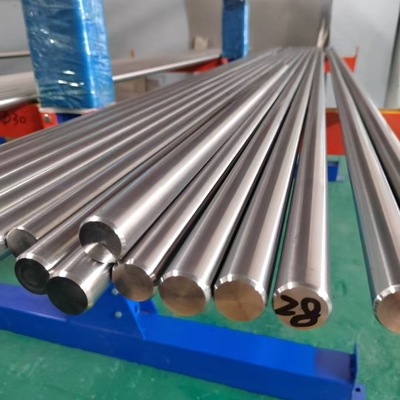

Titanium Medical Rod ASTM F136 Bar ISO13485 Sternal Sutures Artificial Joint

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium And Titanium Alloy | Grade | Grade 5, Ti-6al-4v-eli, Grade 23 |

|---|---|---|---|

| Diameter | 5-30mm, 35-70mm, 80-110mm, 120-900mm | Length | 1000-6000mm |

| Surface | Acid Washing Surface | Standard | ASTM B348, ASTM F136 |

| Model | Ti Forged Block | Width | 400-3000mm, Max 2000mm, Customized, |

| Yield Strength | 828 MPa | Melting Point | 1668°C |

| Elongation | 10% | Origin | China Valley |

| Purity | ≥99.7% | Poisson Ratio | 0.30 |

| Key Words | Titanium Square Bars | Material Grade | BT9 |

| Size | 12.7×12.7×4000mm | Welding Wire Type | MTG |

| Delivert Time | 7-10days | Product Namee | ASTM B348 Titanium Round Bar |

| Highlight | Titanium Medical Rod 3mm,ASTM F136 Titanium Industrial Bar,Medical Titanium Round Rod |

||

Description

Titanium Medical Rod ASTM F136 is a precision-engineered titanium alloy bar used in medical implants and surgical instruments. It offers an exceptional combination of high strength, biocompatibility, and corrosion resistance, making it ideal for orthopedic and surgical applications.

Manufactured in compliance with ASTM F136, ASTM B348, and ISO 13485 standards, this titanium rod (commonly Ti-6Al-4V ELI / Grade 23) ensures excellent mechanical performance and compatibility with the human body.

Typical applications include spinal fusion devices, orthopedic screws, plates, bone nails, and joint replacement components.

Key Features

Manufactured according to ASTM F136 / ISO 13485 standards

Excellent biocompatibility and corrosion resistance

High strength-to-weight ratio

Non-toxic and non-allergenic

Available in a wide range of diameters (3–16 mm and above)

Precision-machined and polished surface finish

Suitable for implant-grade and surgical instrument manufacturing

Specifications

| Item | Description |

|---|---|

| Material Grades | Gr5 (Ti-6Al-4V), Gr5 ELI / Gr23 (Ti-6Al-4V ELI), Gr2 |

| Standards | ASTM F136, ASTM F67, ASTM B348, ISO 13485 |

| Diameter Range | 3 mm – 16 mm (customizable up to 600 mm) |

| Length | 1000 mm – 6000 mm |

| Surface Finish | Polished, Bright, or Ground |

| Tolerance | H6–H9 |

| Technique | Forged and Rolled |

| Stock Availability | Ø5–600 mm (ready stock) |

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 (ELI) | 793 | 759 | 10 |

Chemical Composition (wt%)

| Grade | Fe max | O max | N max | C max | H max | Pd max | Al | V | Others |

|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | Ti Balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | Ti Balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | Ti Balance |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | Ti Balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | Ti Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | Ti Balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | Ti Balance |

| Gr23 | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | Ti Balance |

Applications

-

Orthopedic Implants: Spinal fixation systems, bone plates, and bone screws

-

Joint Replacement: Hip, knee, and shoulder prosthetics

-

Surgical Instruments: Bone drills, reamers, saws, and chisels

-

Dental Implants and Components

-

Medical Devices: Pacemaker housings, stents, and defibrillator cases

-

External Fixation Devices and Intramedullary Nails

-

Research & Development: Used for testing biocompatibility and mechanical properties