-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

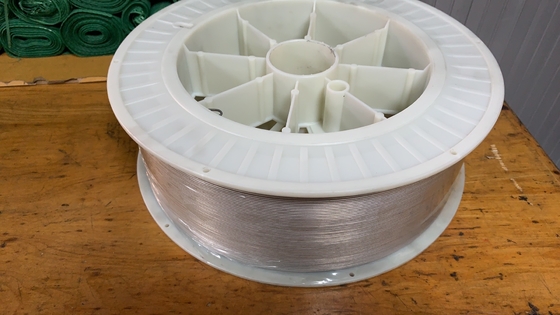

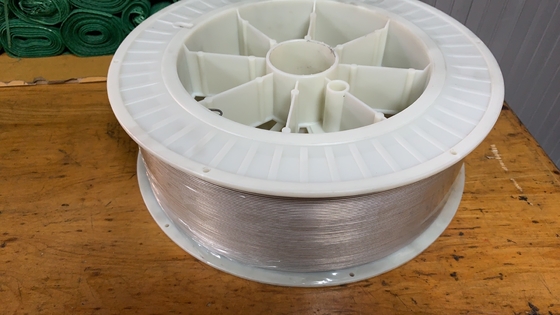

Zirconium 702 Welding Wire UNS R60702 Wire for Pressure Vessel

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Zirconium | OD | 1-5mm |

|---|---|---|---|

| Length | 1000-6000mm | Surface | Polished, Pickling |

| Shape | Straight | MOQ | 10KG |

| Application | Industrial Ceramic | Materials | Zirconium |

| Color | Silver | Availability | Widely Available |

| Electronegativity | 1.33 (Pauling Scale) | Atomic Mass | 91.224 |

| Advantage | OEM Supply | Boiling Point | 4377°C |

| Oxidation States | +4, +3, +2 | Atomic Number | 40 |

| Custom | Available | Forms Available | Wire, Sheet, Rod, Tube, Foil |

| Wall Thickness | 1-5mm | ||

| Highlight | ErTi-2 Titanium Welding Wire,2000mm Titanium Welding Wire,Titanium Welding Wire Polished |

||

Description

Zirconium 702 welding wire is a high-performance wire designed for joining zirconium alloys, especially Zirconium 705, in applications requiring excellent corrosion resistance, thermal stability, and mechanical strength.

It is available in standard diameters ranging from 0.045" to 0.125", and supports multiple welding processes such as:

Gas Tungsten Arc Welding (GTAW / TIG)

Gas Metal Arc Welding (GMAW / MIG)

Shielded Metal Arc Welding (SMAW)

Zr702 wire, primarily composed of zirconium with minor alloying elements, provides reliable weld integrity in corrosive and high-temperature environments such as chemical plants, heat exchangers, and nuclear facilities.

Specifications

| Item | Details |

|---|---|

| Product Name | Zirconium 702 Welding Wire |

| UNS Designation | R60702 |

| Available Sizes | 0.045" – 0.125" (custom sizes available) |

| Welding Methods | TIG, MIG, SMAW |

| Material Grades | Zirconium 702, Zirconium 704, Zirconium 705 |

| Surface Finish | Bright / Pickled |

| Standards | ASTM B493, ASTM B550 |

| Applications | Heat exchangers, chemical processing, aerospace, nuclear components |

Chemical Composition

| Element | Zirconium 702 (R60702) | Zirconium 704 (R60704) | Zirconium 705 (R60705) |

|---|---|---|---|

| Zirconium + Hafnium, min | 99.2 | 97.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 max | 0.2–0.4 | 0.2 max |

| Tin | — | 1.0–2.0 | — |

| Hydrogen, max | 0.005 | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 | 0.05 |

| Niobium | — | — | 2.0–3.0 |

| Oxygen, max | 0.16 | 0.18 | 0.18 |

Physical Properties

| Property | Zirconium 702 (R60702) | Zirconium 704 (R60704) | Zirconium 705 (R60705) |

|---|---|---|---|

| Tensile Strength (min) | 380 MPa | 415 MPa | 550 MPa |

| Yield Strength (min) | 205 MPa | 240 MPa | 380 MPa |

| Elongation (min, %) | 16 | 14 | 16 |

Applications

Zirconium 702 Welding Wire is used across industries where corrosion resistance, heat resistance, and structural stability are essential:

-

Welding zirconium and its alloys (Zr702, Zr705).

-

Fabrication of heat exchangers, boilers, and pressure vessels.

-

Chemical and petrochemical equipment exposed to acids or high-temperature media.

-

Aerospace and marine structures requiring low weight and high durability.

-

Medical and laboratory instruments where biocompatibility is critical.

-

Production of electrodes, battery terminals, fuel injectors, and spark plugs.

-

Fabrication of fasteners, springs, rings, and precision components.

Properties

-

Excellent corrosion resistance in strong acids and alkalis.

-

High mechanical strength and ductility.

-

Low thermal conductivity and excellent heat resistance.

-

Non-magnetic and biocompatible.

-

Smooth welding characteristics and consistent arc performance.

-

Suitable for high-temperature and high-pressure environments.