-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

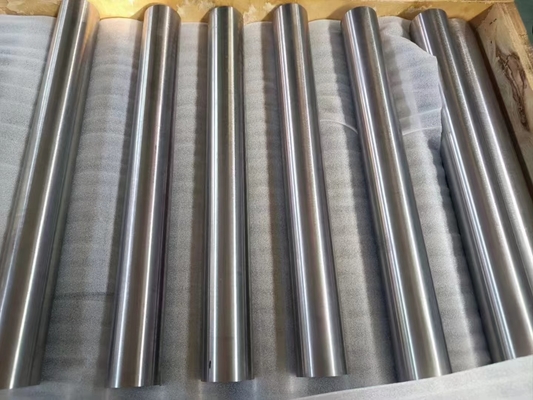

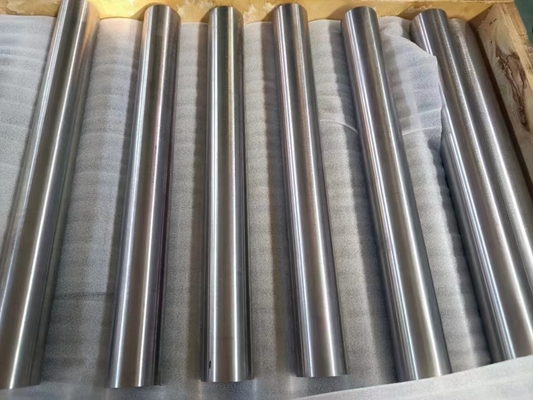

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

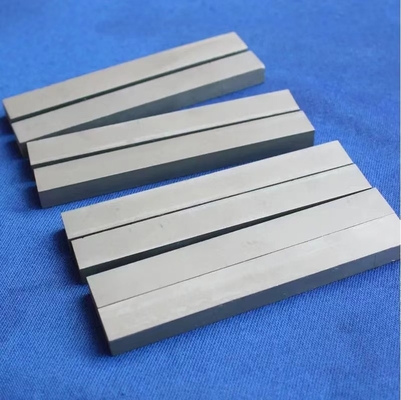

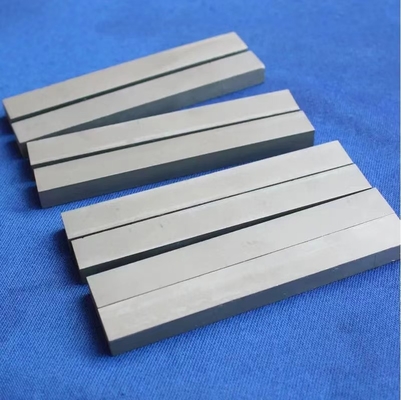

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Zirconium Rods Forged Zr1 Zr2 R60705 Φ5.0-200mm Chemical Aerospace

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTMB550/550M-07(2012) |

| Minimum Order Quantity | 10kgs |

| Price | $320 - $45000/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Diameter | 5.0-200mm | Electrical Conductivity | 16.6 MS/m |

|---|---|---|---|

| Chemical Properties | Reactive With Acids And Alkalis | Availability | Widely Available |

| Forms Available | Wire, Sheet, Rod, Tube, Foil | Length | <5000mm |

| Application | Industrial Ceramic | Custom | Available |

| Color | Silver-gray | Size | 30ml(47*22) |

| Boiling Point | 4377 °C | Package | Wooden Box |

| Technical | Rolled | Surface | Polished |

| MOQ | 10kg | ||

| Highlight | Forged Zirconium Rods,R60705 Zirconium Rods,Chemical Aerospace Zirconium Rods |

||

Production Overview

Zirconium 705 alloys are high-performance materials composed primarily of zirconium with alloying elements such as niobium and trace amounts of nickel, cobalt, chromium, and molybdenum.

These alloys are widely used in nuclear power, aerospace, and chemical industries due to their excellent corrosion resistance, high strength, and radiation shielding properties.

Zr705 rods offer a combination of mechanical durability and corrosion resistance, making them ideal for demanding environments such as:

Cladding for nuclear fuel rods

Pressure vessels and heat exchangers

Aerospace exhaust systems and high-temperature components

Zirconium 705 rod (UNS R60705) is a commercially pure zirconium alloy (≥99.2% purity), with 2–3% niobium added to improve mechanical strength and corrosion resistance.

It is also commonly used in medical implants, chemical processing equipment, and marine applications.

Specifications

| Product Name | Zirconium Rod |

|---|---|

| Grade | National Standard: R60702, R60704, R60705American Standard: Zr1, Zr2 |

| Standard | National Standard: GB/T 8769-201, GB/T 21183American Standard: ASTM B550/B550M-07 (2012) |

| Manufacturing Process | Forging and machining |

| Testing Methods | - Chemical composition testing- Physical property testing- Hardness testing- Metallographic analysis- Non-destructive testing (ultrasonic, penetrant, magnetic particle) |

| Applications | Chemical industry, aerospace, nuclear power, and other high-performance fields |

Chemical Composition

| Element | Zr702 / UNS R60702 | Zr704 / UNS R60704 | Zr705 / UNS R60705 |

|---|---|---|---|

| Zirconium + Hafnium, min | 99.2 | 97.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 max | 0.2–0.4 | 0.2 max |

| Tin | — | 1.0–2.0 | — |

| Hydrogen, max | 0.005 | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 | 0.05 |

| Niobium | — | — | 2.0–3.0 |

| Oxygen, max | 0.16 | 0.18 | 0.18 |

Physical Properties

| UNS Grade Designation | Zirconium 702 (R60702) | Zirconium 704 (R60704) | Zirconium 705 (R60705) |

|---|---|---|---|

| Tensile Strength, min (MPa) | 380 | 415 | 550 |

| Yield Strength, min (MPa) | 205 | 240 | 380 |

| Elongation in 50 mm, min (%) | 16 | 14 | 16 |

Applications

Zirconium 705 rods are utilised in a wide range of industrial and high-technology applications, including:

-

Nuclear Industry

-

Fuel rods and reactor components

-

Pressure tubes and cladding materials

-

-

Chemical Processing

-

Pumps, valves, and heat exchangers for corrosive fluids

-

-

Aerospace & Defense

-

Rocket engine parts, aircraft exhaust systems, and fasteners

-

-

Medical Industry

-

Artificial heart valves, orthopaedic implants, and surgical tools

-

-

Marine & Industrial Equipment

-

Condensers, heat shields, and marine hardware requiring high corrosion resistance

-

Key Advantages

Excellent corrosion resistance in acidic and saline environments

High tensile and yield strength

Outstanding performance under radiation exposure

Non-magnetic and biocompatible

Reliable performance under high temperatures and pressures

Would you like me to turn this into a formatted PDF datasheet with:

Clean tables and section headers

Technical icons for each section (chemical, physical, applications)

Placeholder area for “Product Photo: Zirconium 705 Rod”?