-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

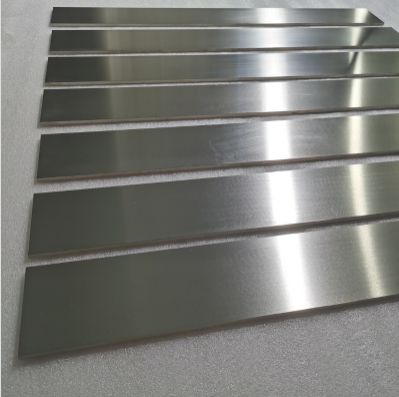

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

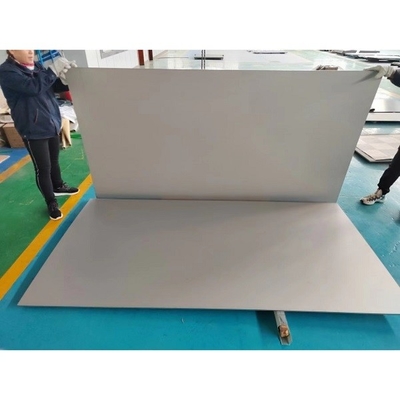

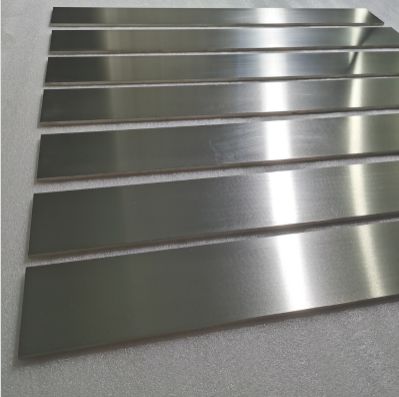

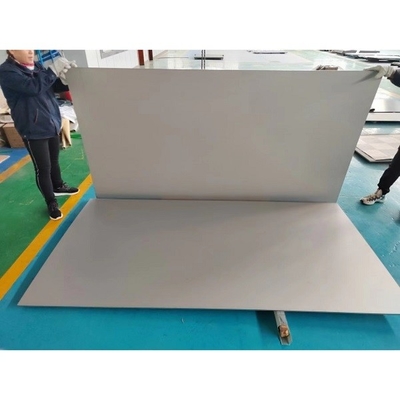

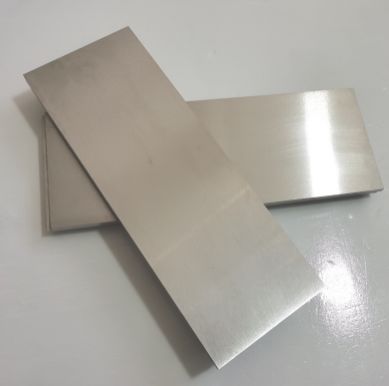

Zirconium Sheet UNS R60702 Sheet ASTM B551 for Industrial use

| Special Features | High Strength-to-weight Ratio And Low Thermal Neutron Absorption Cross-section | Color | Silver-gray |

|---|---|---|---|

| Package | Wooden Box | Availability | Abundant In Nature |

| Magnetic Properties | Non-magnetic | Head Style | Hex, Flange And Customized Shape |

| Atomic Mass | 91.224 | Wall Thickness | 1-5mm |

| Materials | Nickel | Advantage | OEM Supply |

| Usage | Elemental Analysis | Electronegativity | 1.33 (Pauling Scale) |

| Chemical Properties | Reacts With Oxygen, Chlorine, And Sulfur | Surface Roughness | Ra=1.6 |

| Surface | Smooth | ||

| Highlight | ASTM B348 Titanium Rod,Gr5 Titanium Round Rod,Industrial Polished Titanium Rod |

||

Zirconium Sheet / Plate (UNS R60702, R60704, R60705) is a high-performance material known for its exceptional corrosion resistance, strength, and biocompatibility. It is commonly produced from Zirconium 702 alloy, which typically contains 99.2% zirconium, with small additions of niobium, iron, and chromium to enhance its mechanical and chemical stability.

Zirconium 702 sheet is widely used in nuclear reactors, chemical processing equipment, aerospace components, and medical implants due to its outstanding resistance to acids, alkalis, and other corrosive media.

Its low thermal conductivity makes it ideal for use in power generation and electronic applications where heat dissipation must be controlled.

Zirconium sheets can be supplied in a variety of thicknesses ranging from 0.001 to 0.020 inch (0.025 to 0.508 mm) and with different surface finishes, including polished, anodised, etched, and sandblasted.

They can be easily machined, welded, or formed into customised components according to specific engineering requirements.

Chemical Composition of Zirconium Sheet (% by weight)

| Element | UNS R60702 | UNS R60704 | UNS R60705 |

|---|---|---|---|

| Zirconium + Hafnium, min | 99.2 | 97.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 max | 0.2–0.4 | 0.2 max |

| Tin | — | 1.0–2.0 | — |

| Hydrogen, max | 0.005 | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 | 0.05 |

| Niobium | — | — | 2.0–3.0 |

| Oxygen, max | 0.16 | 0.18 | 0.18 |

Physical Properties of Zirconium Sheet

| Property | UNS R60702 | UNS R60704 | UNS R60705 |

|---|---|---|---|

| Tensile Strength, min | 55 ksi / 380 MPa | 60 ksi / 415 MPa | 80 ksi / 550 MPa |

| Yield Strength, min | 30 ksi / 205 MPa | 35 ksi / 240 MPa | 55 ksi / 380 MPa |

| Elongation (in 2 in. or 50 mm), min | 16% | 14% | 16% |

Applications of Zirconium Sheet / Plate

1. Chemical Processing

Used as reactor linings, heat exchangers, and catalyst supports in the production of ethylene and other organic chemicals due to its excellent resistance to strong acids like hydrochloric and sulfuric acid.

2. Nuclear Industry

Serves as a cladding material for nuclear fuel rods to contain uranium fuel and prevent radioactive leakage, thanks to zirconium’s low neutron absorption cross-section.

3. Medical and Imaging Equipment

Employed as radiation shielding to minimise patient exposure in X-ray and medical imaging systems.

Also used in surgical implants for its biocompatibility and resistance to body fluids.

4. Electronics

Applied in semiconductors, capacitors, and high-resistance components because of its stable electrical characteristics and low thermal conductivity.

5. Automotive

Used in exhaust systems, catalytic converters, and brake components where heat resistance and corrosion resistance are critical.

6. Ceramics and Refractories

Incorporated in ceramic tiles and refractory materials for high-temperature applications due to its excellent thermal stability.