-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

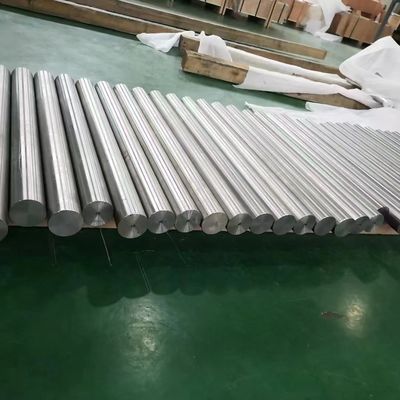

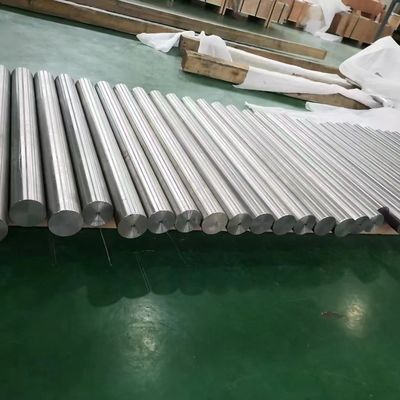

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

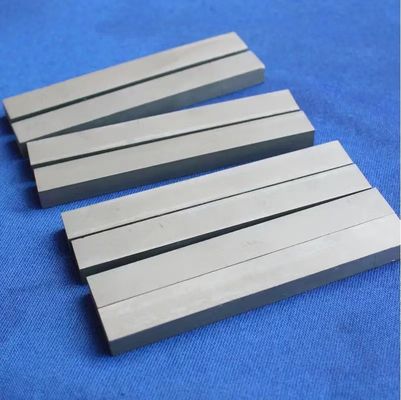

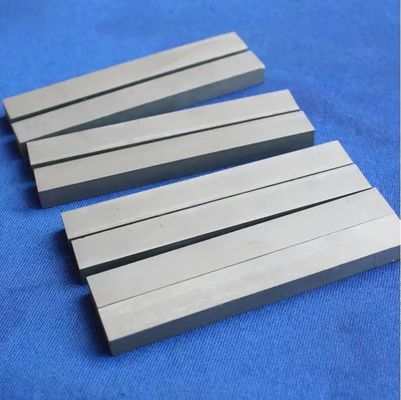

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

UNS R60702 Zirconium 702 Rod for Industrial

| Materials | Titanium | Grade | Zr702/UNS R60702, Zr705/UNS R60705 |

|---|---|---|---|

| Diameter | 3-600mm | Surface | Polished Surface |

| MOQ | 50kg | Standard | ASTM B550 |

| Technical | Forged | Delivery Time | 20-DAYS |

| Highlight | Ti6al4v Round Bar Titanium,600mm Round Bar Titanium,ASTM B348 forged round bar |

||

Zirconium 702 (UNS R60702) is a commercially pure zirconium alloy that offers outstanding corrosion resistance, excellent ductility, and good mechanical strength. It contains a minimum of 99.2% zirconium and hafnium combined, with small amounts of iron and chromium to enhance strength and corrosion resistance.

Unlike stainless steels, Zirconium 702 is not an austenitic alloy and contains no significant chromium or nickel content. It is a non-magnetic, highly corrosion-resistant metal suitable for use in the most aggressive chemical and nuclear environments.

Zirconium 702 rod is commonly used in nuclear power generation, chemical processing, marine, and aerospace applications, where resistance to strong acids, alkalis, and saltwater environments is critical. The material can be machined, welded, and formed easily while maintaining its structural integrity under extreme operating conditions.

Key Features

Excellent corrosion resistance in acidic and alkaline environments

Low thermal neutron absorption – ideal for nuclear applications

High ductility and good formability

Non-magnetic and biocompatible

Reliable performance under high temperature and pressure conditions

Chemical Composition of Zirconium 702 Rod (% by weight)

| Element | UNS R60702 | UNS R60704 | UNS R60705 |

|---|---|---|---|

| Zirconium + Hafnium, min | 99.2 | 97.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 max | 0.2–0.4 | 0.2 max |

| Tin | — | 1.0–2.0 | — |

| Hydrogen, max | 0.005 | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 | 0.05 |

| Niobium | — | — | 2.0–3.0 |

| Oxygen, max | 0.16 | 0.18 | 0.18 |

Physical Properties of Zirconium 702 Rod

| Property | UNS R60702 | UNS R60704 | UNS R60705 |

|---|---|---|---|

| Tensile Strength, min | 55 ksi / 380 MPa | 60 ksi / 415 MPa | 80 ksi / 550 MPa |

| Yield Strength, min | 30 ksi / 205 MPa | 35 ksi / 240 MPa | 55 ksi / 380 MPa |

| Elongation (in 2 in. or 50 mm), min | 16% | 14% | 16% |

Applications of Zirconium 702 Rod

1. Chemical and Petrochemical Processing

Used in valves, pumps, heat exchangers, reactors, and piping systems that handle strong acids such as hydrochloric, sulfuric, and nitric acid.

Excellent resistance to pitting and crevice corrosion ensures long service life.

2. Nuclear Power Industry

Commonly used for nuclear fuel cladding, reactor internals, and containment systems, owing to its low neutron absorption cross-section and high purity.

3. Aerospace and Defence

Applied in aircraft and missile structures, fasteners, and exhaust systems, where a combination of lightweight strength and corrosion resistance is required.

4. Medical and Pharmaceutical Equipment

Utilised for surgical instruments, implants, and prosthetic devices, benefiting from its biocompatibility and resistance to body fluids.

5. Marine and Industrial Applications

Used in heat exchangers, condensers, marine hardware, and desalination equipment due to its excellent resistance to seawater corrosion.

6. Speciality Uses

Sometimes used in military components and decorative jewellery, valued for its lustre, strength, and corrosion resistance.