-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

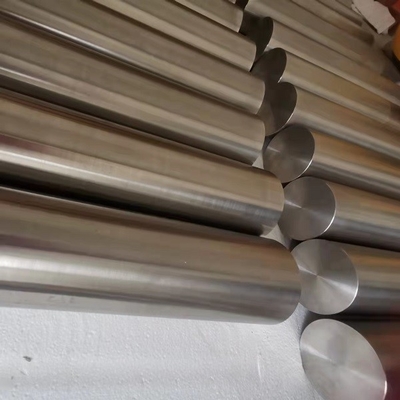

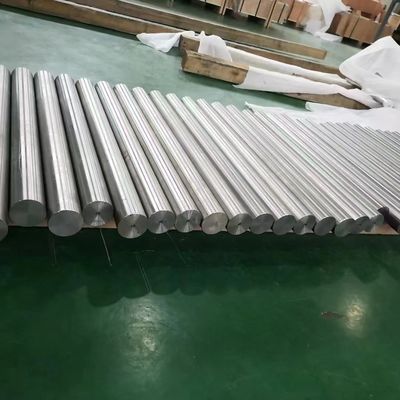

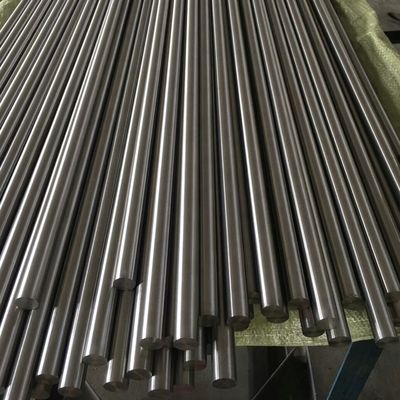

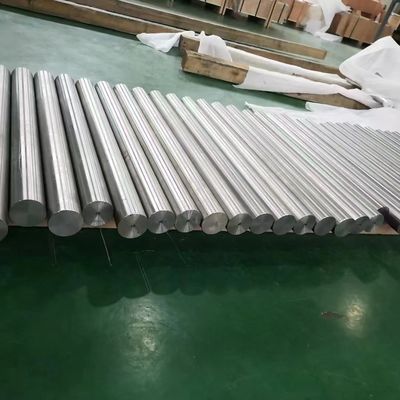

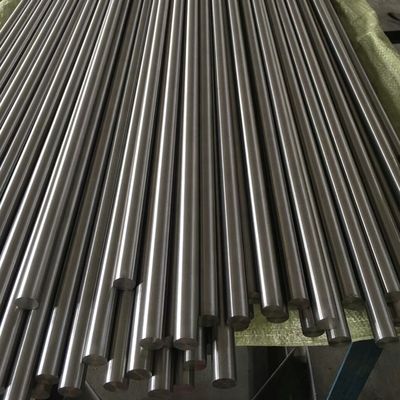

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

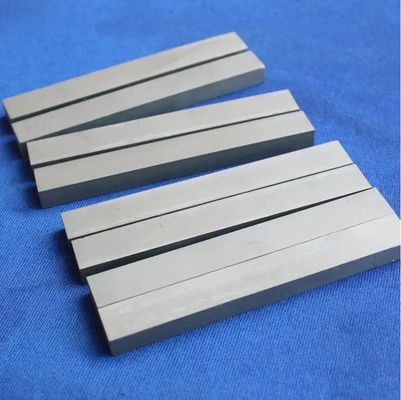

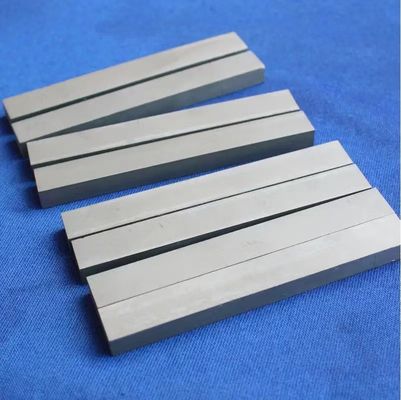

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Zirconium 705 Rod UNS R60705 rod for Industrial

| Materials | Zirconium | Grade | Zirconium 702/UNS R60702 |

|---|---|---|---|

| Diameter | 5-600mm | Surface | Polished |

| MOQ | 50KG | Shape | Round |

| Technical | Forged | Delivery Time | 25 Days |

| Highlight | Gr5 Titanium Round Bar,600mm Titanium Round Bar,3mm titanium hollow bar |

||

Zirconium 705 Rod (UNS R60705) is a high-performance zirconium-niobium alloy known for its excellent corrosion resistance, high strength, and superior performance in high-temperature and high-pressure environments. As a member of the zirconium alloy family, Zirconium 705 contains small amounts of niobium (2–3%), which significantly enhances its mechanical strength and corrosion resistance compared to commercially pure zirconium grades.

This alloy is widely used in nuclear power, aerospace, chemical processing, and medical applications, where durability, purity, and resistance to aggressive environments are essential. The UNS R60705 rod offers excellent formability and weldability, allowing it to be manufactured into complex shapes for specialised components.

Key Features

High corrosion resistance in acids, alkalis, and seawater environments

Excellent strength and stability under high temperatures

Low neutron absorption makes it ideal for nuclear applications

Good biocompatibility, suitable for medical and implant use

Easily fabricated by forging, machining, and welding processes

Chemical Composition of Zirconium 705 Rod (% by weight)

| Element | Zirconium 702 / UNS R60702 | Zirconium 704 / UNS R60704 | Zirconium 705 / UNS R60705 |

|---|---|---|---|

| Zirconium + Hafnium, min | 99.2 | 97.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 max | 0.2–0.4 | 0.2 max |

| Tin | — | 1.0–2.0 | — |

| Hydrogen, max | 0.005 | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 | 0.05 |

| Niobium | — | — | 2.0–3.0 |

| Oxygen, max | 0.16 | 0.18 | 0.18 |

Physical Properties of Zirconium 705 Rod

| Property | Zirconium 702 / UNS R60702 | Zirconium 704 / UNS R60704 | Zirconium 705 / UNS R60705 |

|---|---|---|---|

| Tensile Strength, min | 55 ksi / 380 MPa | 60 ksi / 415 MPa | 80 ksi / 550 MPa |

| Yield Strength, min | 30 ksi / 205 MPa | 35 ksi / 240 MPa | 55 ksi / 380 MPa |

| Elongation (in 2 in. or 50 mm), min | 16% | 14% | 16% |

Applications of Zirconium 705 Rod

1. Nuclear Power Industry

Used for fuel rod cladding, pressure vessels, and heat exchangers due to its low neutron absorption and excellent corrosion resistance in high-temperature water and steam.

2. Chemical Processing

Ideal for pumps, valves, and reactor linings exposed to strong acids and corrosive environments.

Provides long service life and reduced maintenance costs.

3. Aerospace and Defence

Employed in rocket engine components, aircraft exhaust systems, and thermal shields, where high temperature strength and oxidation resistance are required.

4. Medical Applications

Utilised in surgical implants, including artificial heart valves and orthopaedic devices, due to its excellent biocompatibility and resistance to body fluids.

5. Industrial and Marine Uses

Suitable for heat exchangers, condensers, marine hardware, and heat shields, providing durable performance in seawater and corrosive atmospheres.