-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

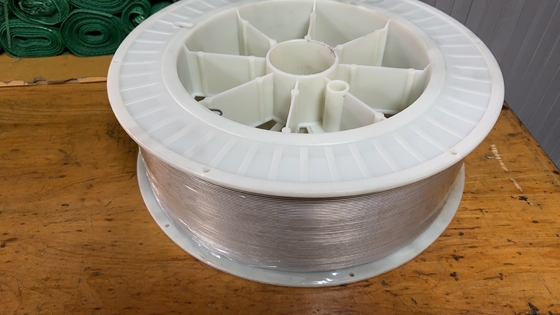

Zirconium 705 Welding Wire Zr705 Wire UNS R60705 Wire for Industrial

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Zirconium | Grade | R60705/Zr 705 |

|---|---|---|---|

| Diameter | 0.5-3mm | Surface | Polished, Pickling, Anodizing |

| MOQ | 10kg | Shape | Straight |

| Length | 900-3000mm | Delivery Time | 15-30 Days |

| Standard | ASTM B550 | Head Style | Hex, Flange And Customized Shape |

| Technical | Forged | Method | Hot Pressing/Dry Pressing |

| Thickness | 0.6-50mm | Chemical Properties | Highly Reactive With Oxygen, Chlorine, And Other Halogens |

| Corrosion Resistance | Excellent | Wall Thickness | 1-5mm |

| Customization | Yes | Electrical Conductivity | 16.4 MS/m |

| Thermal Conductivity | 22.7 W/mK | Availability | Widely Available |

| Application | Industrial Ceramic | ||

| Highlight | Gr23 Titanium Filler Rod,Ti6al4v Titanium Filler Rod,Straight titanium mig welding wire |

||

Description

Zirconium 705 (UNS R60705) is a zirconium-based alloy containing small additions of niobium, titanium, and other alloying elements. It combines excellent strength, corrosion resistance, and oxidation resistance, making it ideal for demanding applications in harsh environments.

Zirconium 705 is widely used in nuclear power generation, aerospace components, and chemical processing equipment due to its ability to withstand high temperatures and aggressive media. It also offers outstanding resistance to stress-corrosion cracking, ensuring durability in critical service conditions.

Zirconium 705 Welding Wire

Zirconium 705 welding wire is specifically designed for welding zirconium and zirconium alloys, particularly Zirconium 705.

It is manufactured in standard diameters ranging from 0.045" to 0.125", suitable for various industrial welding applications.

Zr705 wire can be used in multiple welding processes, including:

Gas Tungsten Arc Welding (GTAW / TIG)

Gas Metal Arc Welding (GMAW / MIG)

Shielded Metal Arc Welding (SMAW)

This alloy provides high weld quality and maintains corrosion and temperature resistance after joining.

Chemical Composition (%)

| Element | Zr702 / R60702 | Zr704 / R60704 | Zr705 / R60705 |

|---|---|---|---|

| Zirconium + Hafnium, min | 99.2 | 97.5 | 95.5 |

| Hafnium, max | 4.5 | 4.5 | 4.5 |

| Iron + Chromium | 0.2 max | 0.2–0.4 | 0.2 max |

| Tin | — | 1.0–2.0 | — |

| Hydrogen, max | 0.005 | 0.005 | 0.005 |

| Nitrogen, max | 0.025 | 0.025 | 0.025 |

| Carbon, max | 0.05 | 0.05 | 0.05 |

| Niobium | — | — | 2.0–3.0 |

| Oxygen, max | 0.16 | 0.18 | 0.18 |

Physical Properties

| Property | Zr702 / R60702 | Zr704 / R60704 | Zr705 / R60705 |

|---|---|---|---|

| Tensile Strength (min) | 55 ksi / 380 MPa | 60 ksi / 415 MPa | 80 ksi / 550 MPa |

| Yield Strength (min) | 30 ksi / 205 MPa | 35 ksi / 240 MPa | 55 ksi / 380 MPa |

| Elongation (min, %) | 16 | 14 | 16 |

Applications

Zirconium 705 Welding Wire is suitable for a wide range of industrial and high-performance applications, including:

-

Nuclear and Aerospace Components – Reactor vessels, heat exchangers, and jet engine parts.

-

Chemical Processing Equipment – Pressure vessels, piping, and storage tanks for corrosive chemicals.

-

Heat Exchangers and Boilers – Components exposed to high temperature and pressure.

-

Medical and Laboratory Instruments – Devices requiring biocompatibility and corrosion resistance.

-

Industrial Fabrication – Fasteners, bolts, springs, rings, and small precision parts.

-

Electrical Components – Electrodes, battery terminals, and high-temperature electrical connectors.

-

Automotive Applications – Components such as spark plugs, fuel injectors, and exhaust system parts.

Key Features

Excellent corrosion and oxidation resistance

High tensile and yield strength

Resistance to stress-corrosion cracking

Suitable for high-temperature and high-pressure environments

Good weldability with stable mechanical properties