-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

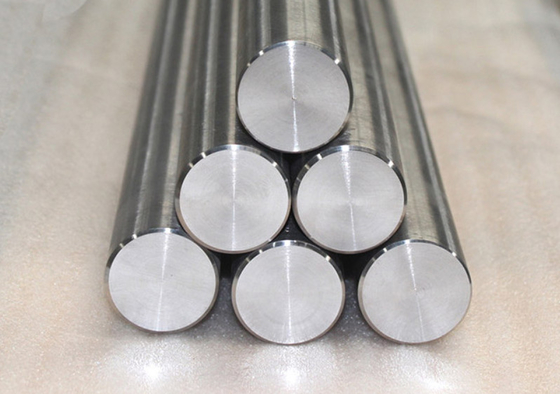

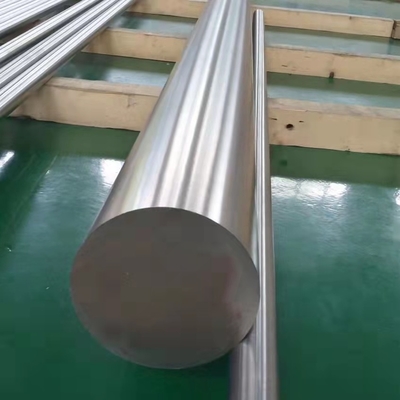

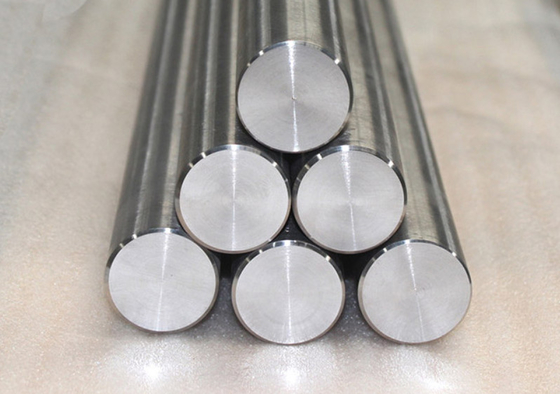

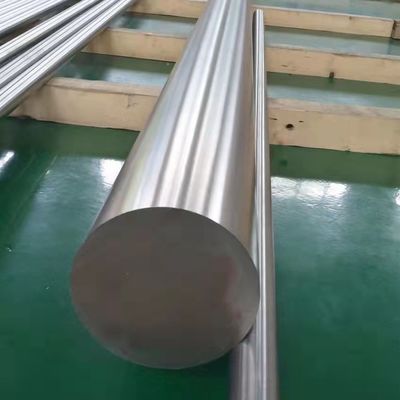

Titanium Grade 9 Gr5 Alloy Rod ASTM B348 For Industry Aerospace

| Place of Origin | CHINA |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001 |

| Model Number | DIN |

| Minimum Order Quantity | 50kg |

| Price | 15usd/kg |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium | Grade | Grade 1,Grade 5, Ti-6al-4v,grade 2,grade 4,grade 23,grade 7,grade 11 |

|---|---|---|---|

| Diameter | 3-600mm | Surface | Polished, Pickling |

| MOQ | 50KG | Standard | ASTM B348,AMS 4904,ASTM F67,ASTM F136 |

| Technical | Forged | Delivery Time | 7-10 Days |

| Highlight | 236 inch Titanium Welding Rod,ASTM B348 Titanium Welding Rod,grade 9 titanium alloy rod |

||

Description

Titanium Grade 9 Rod ASTM B348 is an alpha-beta titanium alloy composed of titanium, aluminum, and vanadium. It offers excellent corrosion resistance, high strength-to-weight ratio, and superior weldability. This alloy is stronger than commercially pure titanium and is widely used in aerospace, medical, chemical, marine, and automotive applications.

Grade 9 titanium rods can be machined using appropriate coolant and high-speed tungsten carbide or cobalt-based tools. They can also be hot or cold formed using hydraulic presses, power brakes, stretch forming, or drop hammer techniques.

Specifications

Material: Titanium Alloy

Grade: Gr9 / Ti 3Al-2.5V

Standard: ASTM B348

Diameter: 3–600 mm (customizable)

Length: 100–6000 mm

Surface Finish: Polished (custom finishes available)

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 | 793 | 759 | 10 |

Chemical Composition (Gr9)

| Element | Max (wt %) |

|---|---|

| Fe | 0.25 |

| O | 0.15 |

| N | 0.03 |

| C | 0.08 |

| H | 0.015 |

| Al | 2.5–3.5 |

| V | 2.0–3.0 |

| Ti | Balance |

Applications

-

Aerospace & Defense: High-performance aircraft components, military defense systems.

-

Medical: Surgical implants, orthopedic devices, and prosthetics.

-

Chemical Processing: Equipment requiring corrosion resistance and strength.

-

Marine: Propellers, fasteners, and structural components in seawater environments.

-

Automotive: Engine components, structural parts, and high-performance vehicles.

Advantages

Excellent strength-to-weight ratio

High corrosion resistance

Good weldability and formability

Biocompatible for medical applications

Easy to machine and fabricate

Can be customized in size, length, and finish