-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

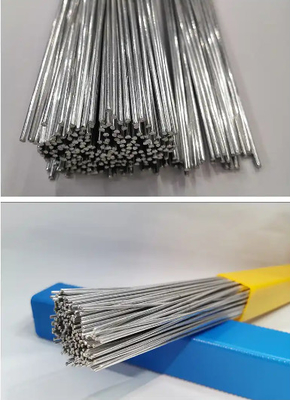

ER4047 Aluminum Welding Wire for SKD11 Metal Stamping Die in Various Shapes

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | AWS A5.10 |

| Minimum Order Quantity | 50kg |

| Price | $10.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Non-Magnetic | Non-magnetic | Color | Silver |

|---|---|---|---|

| Ductility | High Ductility | Electrical Conductivity | High Electrical Conductivity |

| Durability | High | Recyclable | Recyclable |

| Shape | Various Shapes (e.g. Sheets, Plates, Bars, Tubes) | Recyclability | 100% |

| Heat Conductivity | High | Weight | Lightweight |

| Finish | Coating/Anodized/E-Coat | Thermal Conductivity | High Thermal Conductivity |

| Corrosion Resistance | Excellent Corrosion Resistance | Applications | Household |

| Malleability | Highly Malleable | ||

| Highlight | ER4047 Aluminum Welding Wire,Various Shapes Aluminum Welding Wire,SKD11 Aluminum Welding Wire |

||

Description

Aluminum and aluminum alloy welding wire is selected according to the base material type, mechanical properties, and corrosion resistance requirements of the welded joint.

Typically, for welding aluminum and aluminum alloys, thin sheets with similar chemical compositions to the base metal are cut into strips and used as welding wires.

For heat-treated aluminum alloys with a high tendency to hot cracking, welding wires with excellent crack resistance are preferred to ensure weld integrity and mechanical performance.

Specifications

| Item | Description |

|---|---|

| Product Name | Aluminum Alloy Welding Wire |

| Feature | Low Melting Point |

| Color | Silver White |

| Standard | AWS A5.10 |

| Ultimate Tensile Strength | 150–400 MPa |

| Elongation | 5–10% |

| Applications | Aerospace, Automotive, Construction, Shipbuilding, Rail Transit, Machinery, Electronics, Electrical Appliances, and more. |

Applications

1. Aerospace

In the aerospace industry, aluminum welding wire is widely used due to its lightweight and excellent corrosion resistance.

It is essential for joining aluminum alloy components used in aircraft and spacecraft manufacturing, ensuring high structural strength and safety.

2. Automotive Manufacturing

With the growing demand for lightweight vehicles, aluminum alloys have become increasingly popular in automotive production.

Aluminum welding wire is commonly used in body panels, engine cylinder blocks, and chassis components, improving overall performance, strength, and fuel efficiency.

3. Construction Industry

In construction, aluminum welding wire is used to weld doors, windows, curtain walls, and decorative components.

Its corrosion resistance and aesthetic finish make it ideal for modern architectural applications.

4. Shipbuilding

Aluminum welding wire ensures strong, corrosion-resistant joints in ship hulls and marine structures, extending service life and enhancing safety under seawater conditions.

5. Rail Transit

In train and subway manufacturing, aluminum welding wire provides reliable connections for lightweight vehicle structures, contributing to higher strength-to-weight ratios and energy efficiency.

6. Machinery & Electronics

Aluminum welding wire is also applied in mechanical equipment, electrical components, and electronic devices for joining circuit boards and conductive parts, ensuring stable performance and a clean appearance.

Advantages

Low density – lightweight yet strong

Excellent corrosion resistance – ideal for marine and chemical environments

High conductivity – ensures efficient electrical performance

Good crack resistance – suitable for high-strength aluminum alloys

Smooth feeding performance – provides consistent weld quality

Packaging & Delivery

Form: Spools, coils, or straight cut lengths

Diameter Range: Typically 0.8 mm – 3.2 mm (customizable)

Packaging: Vacuum-sealed or moisture-proof packaging available

Delivery Time: 3–10 working days, depending on order quantity

Quality Assurance

Manufactured in accordance with AWS A5.10 and relevant ISO standards.

Each batch undergoes chemical composition analysis, mechanical testing, and surface inspection to ensure stable quality and weldability.