-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

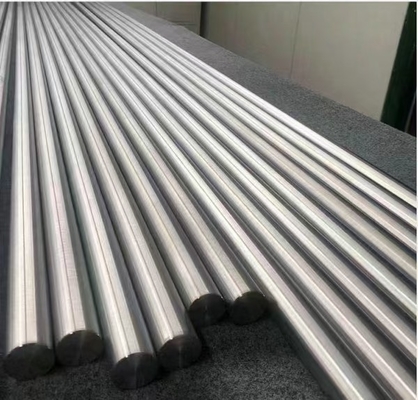

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Aluminum Extruded Tube Corrosion Resistant Apply For Car And Ship

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | Al 6061 T6 |

| Minimum Order Quantity | 50kg |

| Price | $6.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Weight | Lightweight | Ductility | High |

|---|---|---|---|

| Durability | High | Applications | Construction, Automotive, Aerospace, Packaging, Electronics, Etc. |

| Electrical Conductivity | High | Heat Conductivity | High |

| Tensile Strength | Strong | Reflectivity | High |

| Malleability | High | Size | Customizable |

| Corrosion Resistance | Excellent | Finish | Coating/Anodized/E-Coat |

| Recyclability | 100% | Material | Aluminum |

| Shape | Customized | ||

| Highlight | Car Aluminum Extruded Tube,Ship Aluminum Extruded Tube,Corrosion Resistant Aluminum Extruded Tube |

||

Description

An aluminum tube is a type of non-ferrous metal pipe made by extruding pure aluminum or aluminum alloy into a hollow cross-section along its longitudinal length.

It may feature one or more enclosed passages, with uniform wall thickness and consistent cross-section. The product can be supplied in straight lengths or coils.

Aluminum tubes are widely used in automobiles, ships, aerospace, aviation, electrical appliances, agriculture, machinery, and home industries due to their excellent strength-to-weight ratio, corrosion resistance, and versatility.

Specification

| Product Name | Aluminum Seamless Tubes |

|---|---|

| Material | Alloy 6063 / 6061 / 6005 / 6060 T5 / T6 |

| Thickness | 0.3 – 10 mm |

| Color | Silver |

| Processing | Heat Extrusion |

| Surface | Mill Finish |

| Type | OEM Aluminum Extrusion Profiles |

| Port | Foshan / Guangzhou / Shenzhen |

Advantages of the Aluminum Tube

-

Advanced Welding Technology:

Suitable for industrial production of thin-wall copper-aluminum pipe welding — a world-class technical challenge — enabling effective copper-to-aluminum replacement in air conditioner piping. -

Extended Service Life:

Since refrigerants are moisture-free, the inner walls of aluminum pipes resist corrosion, ensuring long-term durability. -

Energy Efficiency:

Aluminum’s lower heat transfer rate improves thermal insulation between indoor and outdoor air conditioner units, saving energy and reducing power consumption. -

Excellent Bending and Formability:

Aluminum tubes have good flexibility and are easy to bend, install, and move, providing excellent adaptability for complex designs.

Applications

-

Aerospace:

Widely used in aircraft engines, fuselages, and structural connectors. Aluminum seamless tubes combine light weight, high strength, corrosion resistance, and wear resistance, offering a cost-effective alternative to titanium and stainless steel. -

Automotive Industry:

Used in engine components, chassis, and wheel hubs. Their light weight and corrosion resistance improve fuel efficiency and enhance vehicle safety. -

Electronics:

Aluminum seamless tubes are used in radiators and electronic components. With high thermal conductivity and stability, they enhance heat dissipation and improve component reliability. -

Construction:

Commonly applied in decorative materials, curtain walls, and architectural tubing. Aluminum’s corrosion and heat resistance ensure long-lasting performance, while smooth and colored surfaces enhance aesthetic appeal. -

Industrial Applications:

Utilized in air compressors, chemical equipment, and oil drilling tools. Their excellent thermal and electrical conductivity make them suitable for demanding industrial environments. -

Medical Devices:

Non-toxic, tasteless, and rust-resistant, aluminum tubes are used for infusion tubes, respirators, and other medical equipment. -

Other Fields:

Aluminum seamless tubes are also used in electrical busbars, solar and renewable energy systems, and compressed gas storage.

In summary:

Aluminum seamless tubes are valued for their light weight, high strength, and corrosion resistance. With ongoing technological advancements, their range of applications continues to expand.