-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

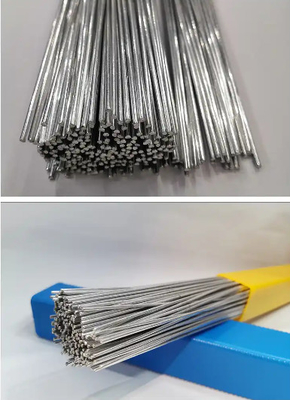

Lightweight Aluminum Welding Alloy Wire ER4043 ER5356 ER5183 0.8mm 1.2mm

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | AWS A5.10 |

| Minimum Order Quantity | 10kgs |

| Price | $10.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Ductility | High | Tensile Strength | Strong |

|---|---|---|---|

| Thermal Conductivity | High | Material | Aluminum |

| Conductivity | High | Reflectivity | High |

| Weight | Lightweight | Size | Customizable |

| Recyclability | 100% | Heat Conductivity | High |

| Color | Silver | Electrical Conductivity | High |

| Durability | High | Malleability | High |

| Highlight | ER5356 Aluminum Welding Alloy Wire,0.8mm Aluminum Welding Alloy Wire,ER5183 Aluminum Welding Alloy Wire |

||

Description

Aluminum and aluminum alloy welding wire is chosen based on the type of base material, required mechanical properties, and joint corrosion resistance.

When welding aluminum and its alloys, thin sheets of similar chemical composition to the base metal are typically cut into strips and used as welding wire.

For heat-treated aluminum alloys that have a high tendency toward hot cracking, welding wires with excellent crack resistance are preferred to ensure joint quality and structural integrity.

Specification

| Product Name | Aluminum Alloy Welding Wire |

|---|---|

| Feature | Low Melting Point |

| Color | Silver White |

| Standard | AWS A5.10 |

| Ultimate Strength (≥ MPa) | 150 – 400 MPa |

| Elongation (≥ %) | 5 – 10% |

| Application | Aerospace, automotive manufacturing, construction, shipbuilding, rail transit, machinery, electronics, and electrical appliances |

Applications

1. Aerospace

Aluminum welding wire is widely used in the aerospace industry due to its lightweight, high strength, and corrosion resistance.

It serves as a key joining material in the production of aircraft and spacecraft structures, ensuring safety, durability, and performance reliability.

2. Automotive Manufacturing

As the automotive industry moves toward lightweight design, aluminum alloys are increasingly used for body panels, engine blocks, and other structural parts.

Aluminum welding wire enables strong and durable joints, improving fuel efficiency, handling, and vehicle performance.

3. Construction Industry

In the construction field, aluminum welding wire is commonly used for welding aluminum alloy doors, windows, curtain walls, and façade components.

Its corrosion resistance and aesthetic appeal make it ideal for modern architectural applications.

4. Shipbuilding

Aluminum welding wire is used in shipbuilding to join hulls, decks, and structural components.

It ensures strong, corrosion-resistant joints that can withstand harsh marine environments.

5. Rail Transit

Used in the manufacturing of trains, subways, and light rail vehicles, aluminum welding wire helps maintain the structural strength and safety of high-speed, lightweight transportation systems.

6. Machinery and Electronics

Aluminum welding wire is also applied in machinery, electronic equipment, and electrical appliances.

It provides reliable connections for components such as circuit boards, casings, and conductive parts, combining strength with good appearance.