-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

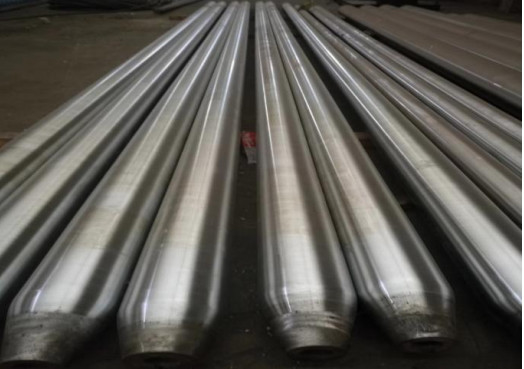

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

High Electrical Conductivity Silver Aluminum Rods for Aircraft Structure Rivets 1050 1060 2A16 LY16 2024

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001:2015 |

| Model Number | AMS4050 |

| Minimum Order Quantity | 50kg |

| Price | $5.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Durability | High | Ductility | High |

|---|---|---|---|

| Applications | Household | Recyclability | 100% |

| Material | Aluminum | Size | Customizable |

| Reflectivity | High | Electrical Conductivity | High |

| Thermal Conductivity | High | Heat Resistance | Good |

| Tensile Strength | Strong | Color | Silver |

| Heat Conductivity | High | Finish | Coating/Anodized/E-Coat |

| Corrosion Resistance | Strong | ||

| Highlight | 2024 Aluminum Rods,High Electrical Conductivity Aluminum Rods,Aircraft Structure Aluminum Rods |

||

Description

An aluminum rod is a fundamental aluminum product produced through melting, purification, degassing, impurity removal, slag removal, and continuous casting.

The resulting rods feature excellent mechanical properties, corrosion resistance, and thermal conductivity.

Depending on the alloying elements added, aluminum rods are divided into eight main series, each with distinct properties and applications.

Specifications

| Item | Description |

|---|---|

| Product Name | Aluminum Rod |

| Model Number | 6061, 6063 |

| Application | Industrial |

| Technique | Extruded |

| Surface | Mill Finish |

| Material | 6060, 6061, 6063, 6082 |

| Length | 0–6000 mm |

| Hardness | 99–200 HB |

| Alloy or Not | Is Alloy |

| Aluminum Content (Min) | 90–99.9% |

| Yield Strength (≥ MPa) | 241 MPa |

| Ultimate Tensile Strength (≥ MPa) | 276 MPa |

| Temper | T3 – T8 |

| Processing Service | Cutting |

| Applications | Aerospace, Mechanical Manufacturing, Electronics, Packaging Industry, Construction, and more |

Classification of Aluminum Rods

-

1000 Series – Pure aluminum (≥99%), excellent corrosion resistance and conductivity.

-

2000 Series – Aluminum–copper alloys, high strength, used in aerospace and machinery.

-

3000 Series – Aluminum–manganese alloys, strong corrosion resistance, often used in construction.

-

4000 Series – Aluminum–silicon alloys, good wear resistance and low thermal expansion.

-

5000 Series – Aluminum–magnesium alloys, lightweight and strong, suitable for marine environments.

-

6000 Series – Aluminum–magnesium–silicon alloys, excellent formability and weldability (e.g., 6061, 6063).

-

7000 Series – Aluminum–zinc alloys, very high strength, ideal for aerospace and defense.

-

8000 Series – Specialized alloys with unique electrical and chemical characteristics.

Applications

1. Aerospace

Aluminum rods are essential in aircraft, rockets, and spacecraft components due to their lightweight, high strength, and corrosion resistance, meeting the stringent requirements of the aerospace industry.

2. Machinery

Widely used in mechanical manufacturing, aluminum rods are used to make gears, propellers, engine parts, and structural components. Their use reduces both weight and production cost.

3. Electronics

Due to excellent electrical and thermal conductivity, aluminum rods are used in radiators, conductors, connectors, and electronic housings, ensuring efficient heat and power transfer.

4. Packaging Industry

Aluminum rods can be processed into barrels, tubes, and containers with strong corrosion resistance and tight sealing, suitable for food, pharmaceuticals, and chemical packaging.

5. Building & Construction

In the construction field, aluminum rods are used for frames, beams, railings, doors, and window components. Their light weight and resistance to rust make them ideal for modern architecture.

6. Electric Power Industry

Used to manufacture wires, cables, transmission lines, and electrical components, aluminum rods provide high conductivity and oxidation resistance for power systems.

7. Transportation

Aluminum rods are utilized in automotive, rail, and marine industries for body panels, wheels, frames, and hulls, offering a balance of lightness, strength, and durability.

8. Chemical Industry

Their acid and alkali resistance make aluminum rods suitable for chemical reactors, pipelines, tanks, and equipment operating in corrosive environments.

9. Furniture & Household Products

Aluminum rods are used to manufacture tables, chairs, lighting fixtures, cookware, and utensils, valued for their durability and modern appearance.

10. Sporting Goods

Pure aluminum rods are used in golf clubs, tennis rackets, and bicycle frames, combining light weight with high mechanical performance.

11. Medical Equipment

In the medical field, aluminum rods are used in surgical instruments, medical devices, and hospital equipment due to their non-toxic and corrosion-resistant nature.

12. Environmental Protection Equipment

Used in waste management and water treatment facilities, aluminum rods offer long service life and corrosion resistance.

13. Crafts & Decorations

Pure aluminum rods are also suitable for artworks, decorative lighting, sculptures, and ornaments, appreciated for their shine and malleability.

Key Features

Lightweight and strong

Excellent corrosion and oxidation resistance

Good electrical and thermal conductivity

High formability and machinability

Suitable for anodizing and surface finishing

Recyclable and environmentally friendly

Packaging & Delivery

-

Form: Straight rods or coils

-

Surface Finish: Mill finish or customized

-

Length: Up to 6000 mm (customizable)

-

Packaging: Bundled, wrapped, or wooden crate

-

Delivery Time: 7–15 working days, depending on quantity

Quality Assurance

All aluminum rods are manufactured under strict quality control in accordance with international standards (ASTM, GB, EN, ISO).

Every batch is inspected for chemical composition, mechanical strength, and surface integrity to ensure consistent and reliable performance.