-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

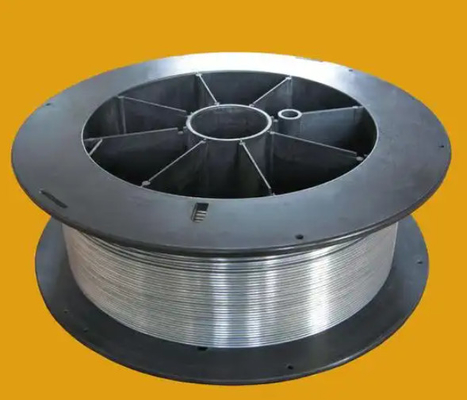

Aluminum Wire 0.18-0.27mm Corrosion Resistance Aluminium Alloy Netting

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | IEC 60086 |

| Minimum Order Quantity | 50kg |

| Price | $6.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Reflectivity | Highly Reflective | Electrical Conductivity | High Electrical Conductivity |

|---|---|---|---|

| Recyclability | Recyclable | Weight | Lightweight |

| Thermal Conductivity | High Thermal Conductivity | Heat Conductivity | High |

| Heat Resistance | Heat Resistant | Color | Silver |

| Applications | Household | Material | Aluminum |

| Cost-effectiveness | Cost-effective | Finish | Coating/Anodized/E-Coat |

| Shape | Various Shapes Available | Malleability | Highly Malleable |

| Versatility | Versatile In Use | ||

| Highlight | 0.18-0.27mm Aluminium Alloy Netting,Corrosion Resistance Aluminium Alloy Netting,Aluminium Alloy Netting |

||

Description

Aluminum alloy wire is produced by drawing aluminum alloy steel wire rods through precision dies.

This wire offers excellent resistance to acids and alkalis, strong corrosion resistance, good toughness, and high tensile strength.

It maintains its color and performance stability even at temperatures up to 120°C, making it suitable for demanding industrial and environmental conditions.

Specifications

| Item | Description |

|---|---|

| Product Name | Aluminum Alloy Wire |

| Condition | Bright, Soft |

| Treatment | Hydrogen Annealing |

| Model Number | AFA 79B, Sulzer Metco 405 |

| Standard Sizes | 1.60 mm and 2.00 mm |

| Other Sizes | Available upon request |

| Applications | Construction, Arts & Crafts, Weaving Nets, Communication Equipment, Medical Devices, Brushes, Steel Cables, Filters, High-Pressure Pipes, and other industries |

Applications

1. Electrical Manufacturing

Aluminum wire has excellent electrical and thermal conductivity.

Although its conductivity is about two-thirds that of copper, its density is only one-third, meaning it weighs half as much for the same current-carrying capacity.

Its natural oxide film also provides surface insulation, making it ideal for electrical cables, conductors, and appliance components.

2. Packaging Materials

Thanks to its high ductility, aluminum wire can be processed into foil, strips, and sheets.

These materials are widely used for packaging food, medicine, cosmetics, and consumer goods due to their lightweight and protective properties.

3. Heat Exchangers

With three times the thermal conductivity of iron, aluminum is an excellent material for heat exchangers, radiators, and cookware, ensuring efficient heat transfer and energy savings.

4. Chemical Equipment

Aluminum forms a dense oxide film that provides natural corrosion protection, making it suitable for chemical reactors, medical instruments, refrigeration systems, and petroleum refining equipment.

5. Architectural Decoration

Aluminum wire can be rolled into plates, tubes, and profiles used in curtain walls, doors, windows, railings, and other decorative applications.

Its light weight, corrosion resistance, and smooth surface make it popular in modern architecture.

6. Coatings

Finely powdered aluminum, with its silver-white luster, is commonly used in automotive, appliance, and furniture coatings, providing both aesthetic appeal and surface protection.

7. Welding Material

Aluminum wire is also used as a welding material in TIG (argon arc welding) and MIG (arc welding) processes for joining aluminum and other metal products.

8. Aluminum Alloy Products

By alloying aluminum wire with other elements, various high-performance aluminum alloys can be produced for use in aerospace, automotive, and construction industries.

9. Battery Anode Material

Aluminum wire serves as an anode material in lithium-ion and aluminum batteries, offering large capacity, long cycle life, and high safety, making it ideal for mobile devices and electric vehicles.

10. Nanomaterials

Through nanotechnology, aluminum wire can be refined into nanometer-scale aluminum wires, featuring high specific surface area and excellent catalytic activity, used in catalysts, sensors, and advanced composites.

Advantages

Excellent corrosion and oxidation resistance

High strength-to-weight ratio

Good thermal and electrical conductivity

Resistant to acid, alkali, and high temperature (up to 120°C)

Smooth surface finish and good formability

Suitable for industrial, decorative, and high-tech applications

Packaging & Delivery

Form: Coils, spools, or straight lengths

Diameter Range: 1.6 mm, 2.0 mm (custom sizes available)

Surface: Bright finish

Packaging: Moisture-proof or vacuum-sealed options

Delivery Time: 3–10 working days, depending on order quantity

Quality Assurance

All aluminum alloy wires are produced under strict quality control systems, ensuring consistent chemical composition, tensile strength, and surface finish.

They conform to relevant international standards (such as AWS and ISO) for industrial and engineering applications.