-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

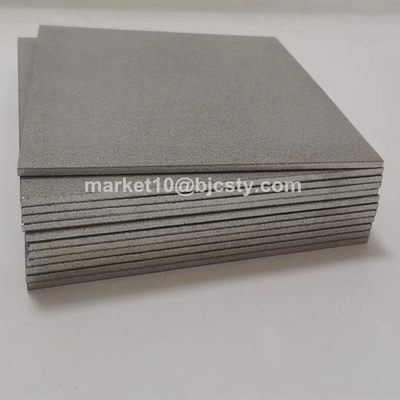

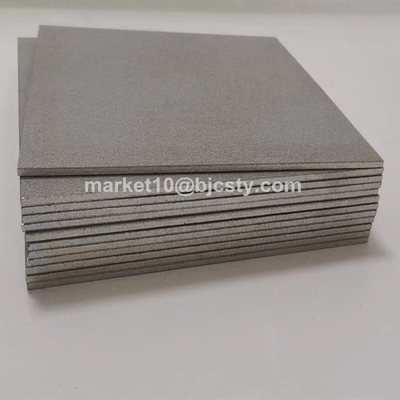

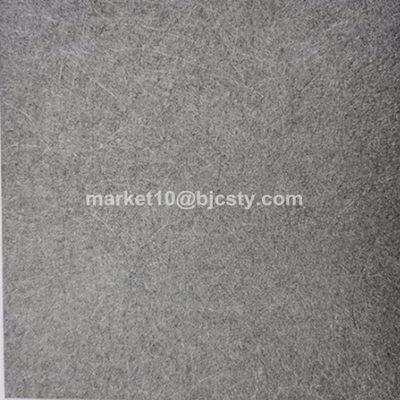

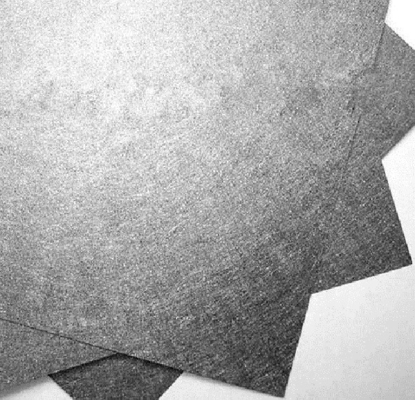

Dia 200x1mm Pure Titanium Metal Sintered Porous Filter Disc/Plate

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001:2015 |

| Minimum Order Quantity | 10kgs |

| Price | $35.00 - $125.00/ kg |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Operating Temperature | Up To 600°C | Working Temperature | 0-100℃ |

|---|---|---|---|

| Thickness | 1-5mm | Filtration Area | 0.3-1.0m2 |

| Compressive Strength | ≥0.6MPa | Filter Medium | Sintered Porous Metal |

| Specific Surface Area | 10-40cm2/cm3 | Filter Type | Sintered Porous Filter |

| Type | Plate, Disc | Working Pressure | 3.0Mpa |

| Length | 2-1000mm | Filter Rating | 1-100um |

| Dimension | Customized | Size | Customizable |

| Heat Resistance | High | ||

| Highlight | Pure Titanium Sintered Porous Filter,Dia 200x1mm Sintered Porous Filter,200x1mm Sintered Porous Filter |

||

Introduction

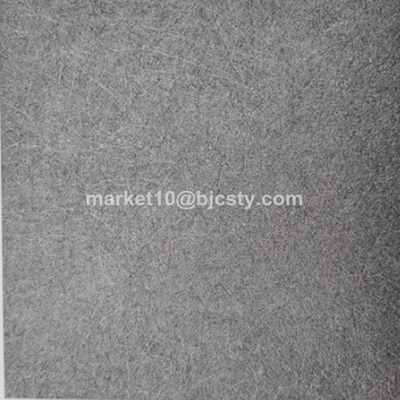

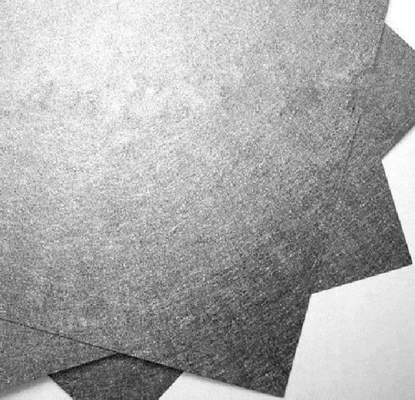

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance.

They provide excellent permeability, precise pore size control, stable shape, high filtration accuracy, wear resistance, good mechanical properties, and outstanding heat conduction, heat resistance, and dissipation.

Additionally, these filters can be repeatedly cleaned and reused, ensuring long service life and cost efficiency.

Specifications

| Product name | Sintered Filter |

|---|---|

| Material | Pure Titanium / SS316L / Bronze |

| Size | OD 20–80 × WT 2.5–3.0 × L 10–1200 mm |

| Filter accuracy | 0.5–80 μm |

| Connection | Customized according to customer requirements |

| Application | Sparging, Separation and Filtration, Carbonisation, Liquid Filtration, etc. |

Parameters

| Filter Accuracy (μm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Application

Sintered metal filters are widely used in the electronics, water treatment, food, biotechnology, chemical, petrochemical, metallurgical, and gas purification industries, representing a new generation of durable and efficient filtration materials.

Typical Applications Include:

-

Sparging and gas diffusion

-

Separation and filtration

-

Carbonisation

-

Liquid filtration

-

Catalyst recovery

-

Steam filtration

-

Slurry oil filtration

-

Flame arrestors

-

Silencing

-

Fluid distribution and control

-

Semiconductor processing

-

Fuel cell stacks

-

Coating electrodes

-

Damping

-

Heat exchange

-

Bio-implants

Properties

-

Uniform pore size and high separation efficiency.

-

High porosity with low filtration resistance and strong permeability.

-

Excellent chemical stability — resistant to acid, alkali, and oxidation.

-

Stable morphology, no particle shedding, compliant with food and pharmaceutical GMP standards.

-

Strong mechanical strength, low differential pressure, and large flow rate.

-

Anti-microbial properties, does not react with microorganisms.

-

Easy online regeneration and cleaning; long operational life.

-

Excellent biocompatibility, ideal for biological, food, pharmaceutical, and medical industries.

-

Effective electromagnetic shielding performance.

-

Good damping and vibration resistance.