-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

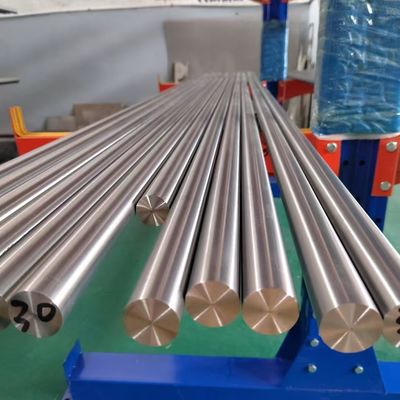

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

ASTM F136 TC4 Gr5eli Round Bar Titanium Small Rod Pharmaceutical Industry

| Place of Origin | China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO 9001 |

| Model Number | ASTM |

| Minimum Order Quantity | 50kg |

| Price | 15usd/kg |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 50T/MONTH |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium | Grade | Grade 1,Grade 5, Ti-6al-4v,grade 2,grade 4,grade 23,grade 7,grade 11 |

|---|---|---|---|

| Diameter | Customizable | Surface | Polished, Pickling |

| MOQ | 50kg | Standard | ASTM B348,AMS 4904,ASTM F67,ASTM F136 |

| Technical | Forged | Delivery Time | 15-DAYS |

| Hardness | 285-340HB | Color | Silvery |

| Elongation | Min. 24% | Size | Diameter 3mm-300mm, Length Up To 6000mm |

| Surface Finish | Polished | Inventory | Large Stock |

| Diameter Tolerance | H7, H8, H9 | Type | Solid Ball, Hollow Ball |

| Density | 4.51 G/cm3 | Material | Titanium |

| Origin | China Valley | Processing Equipment | CNC Lathe, Hydraulic Press, Rolling Mill |

| Sample | Avaliable,Hot Sale Gr1 Titanium Bar | Production Standards | ASTM B348, ASME SB348 |

| Highlight | ASTM F136 Titanium Round Bar,ASTM B348 Titanium Round Bar,AMS 4904 titanium round rod |

||

Description

The Medical Titanium Rod is a high-quality titanium material produced through rolling or forging processes. It offers excellent mechanical properties, corrosion resistance, and biocompatibility, making it ideal for medical, dental, and aerospace applications.

Medical titanium rods are manufactured according to GB/T13810-2007, ASTM F67, ASTM F136, and ASTM F1472 standards, ensuring compliance with international biomedical and engineering requirements.

They are available in both commercially pure titanium (Grades 1–4) and titanium alloys (Grades 5 and 23 ELI), which provide higher strength while maintaining excellent tissue compatibility.

Specifications

| Parameter | Specification |

|---|---|

| Product Name | Medical Titanium Rod / Bar |

| Manufacturing Method | Rolled: Ø8–40 mm × L; Forged: Ø40–150 mm × L |

| Stock Diameter Range | Ø5–600 mm |

| Length | 1000–6000 mm |

| Available Grades | Gr2, Gr5 ELI, Gr23 (Ti-6Al-4V ELI) |

| Standards | ASTM F67, ASTM F136, ASTM F1472, GB/T13810-2007 |

| Tolerance | H6, H7, H8, H9 |

| Surface Finish | Black, Polished, or Bright Surface |

| Metallographic Structure | Pure titanium grain size ≥5; TC4 alloy meets A1–A9 standard |

| Technical Process | Forged and Precision Machined |

| Applications | Medical Implants, Orthopedic Devices, Aerospace Components |

Physical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 (ELI) | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe max (%) | O max (%) | N max (%) | C max (%) | H max (%) | Pd (%) | Al (%) | V (%) | Mo (%) | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | — | — | — | — | Balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | — | — | — | Balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | — | — | — | — | Balance |

| Gr5 | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | — | 5.5–6.7 | 3.5–4.5 | — | Balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | — | — | — | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | — | 2.5–3.5 | 2.0–3.0 | — | Balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | — | 0.6–0.9 | 0.2–0.4 | — | Balance |

| Gr23 (ELI) | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | — | 5.5–6.5 | 3.5–4.5 | — | Balance |

Applications

-

Medical Field:

Orthopedic implants (bone screws, plates, and hip stems)-

Dental implants and abutments

-

Surgical instruments and fixation devices

-

-

Aerospace Industry:

-

Aircraft fasteners, engine parts, and structural components

-

-

Industrial & Engineering:

-

High-performance equipment requiring light weight and high strength

-

Key Features

Exceptional biocompatibility and non-toxicity

Excellent corrosion resistance in body fluids and saline environments

High strength-to-weight ratio for lightweight applications

Superior fatigue resistance for long-term implant stability

Precision machining and polishing for surgical-grade finish

Quality Assurance

All medical titanium rods are produced under strict quality control and tested for:

Chemical composition accuracy

Tensile and yield strength

Surface integrity and finish

Ultrasonic and eddy current inspection

Ordering Information

MOQ: Negotiable (sample orders accepted)

Lead Time: 7–15 working days

Packaging: Vacuum-sealed or medical-grade plastic wrapping in wooden crates

Customization: Dimensions, tolerance, and surface finish available upon request