-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Sodium Hypochlorite Generator for Disinfection / Water Treatment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Working Current | 650-800A | Pt Purity | 99.96% |

|---|---|---|---|

| Conductivity | Good | Diameter | Customized |

| Advantage | Effective.long Working Life.best | Application | Electrolysis |

| Highlight | Disinfection Sodium Hypochlorite Generator,Water Treatment Sodium Hypochlorite Generator |

||

Sodium Hypochlorite Generator for Disinfection / Water Treatment

What is a Sodium Hypochlorite Generator?

A sodium hypochlorite generator is a device that electrolyzes brine (NaCl solution) to produce sodium hypochlorite (NaClO) on-site. It is widely used in disinfection, water treatment, and environmental sanitation.

Working Principle

Electrochemical Reactions:

By passing a direct current through a diluted brine solution (typically 3–5%), the following reactions occur:

At the Anode (Oxidation):

At the Cathode (Reduction):

Sodium Hypochlorite Formation:

The final product is sodium hypochlorite (NaClO), a powerful oxidizing disinfectant.

System Components

| Module | Description |

| Brine Preparation System | Mixes industrial salt with water to achieve a specific concentration. |

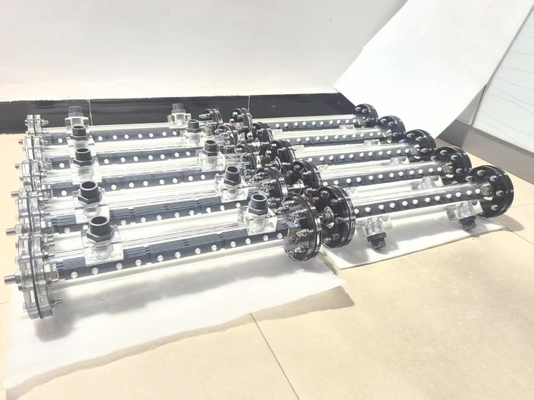

| Electrolytic Cell | Core reaction chamber containing anode and cathode. |

| Rectifier Power Supply | Provides stable DC current (e.g., 24V, 48V). |

| Dosing Pump/System | Controls the dosing rate of the hypochlorite solution. |

| Hydrogen Vent System | Safely discharges hydrogen gas generated during electrolysis. |

| Control System (PLC) | Automates operations such as polarity reversal and dosing. |

Anode Material Features

The anode typically uses a titanium substrate (e.g., GR1/TA1) coated with MMO (Mixed Metal Oxides) such as ruthenium and iridium oxides.

Key advantages:

-

Excellent stability and corrosion resistance

-

High electrocatalytic activity

-

Supports polarity reversal to extend electrode lifespan

Advantages

| Benefit | Description |

| On-site Generation | Eliminates risks of storing or transporting chlorine. |

| Safe Operation | Uses low-concentration brine and low voltage; no free chlorine gas is released. |

| Low Operating Cost | Main consumables are salt and electricity. |

| Environmentally Friendly | No heavy metal contamination. |

| High Automation | Suitable for unattended or remote operation. |

| Wide Application | Used in municipal, industrial, medical, and residential water systems. |

Typical Applications