-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

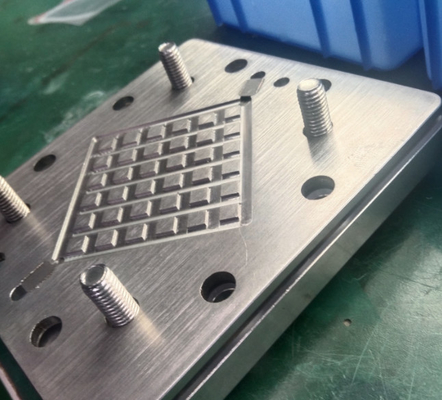

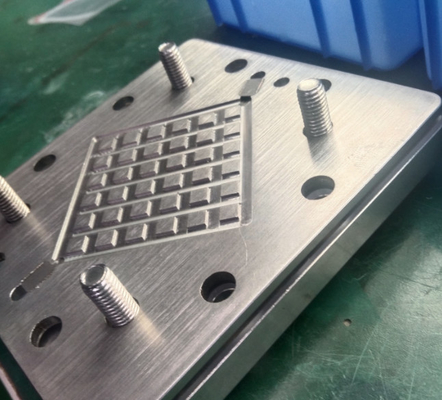

Application Of Titanium Bipolar Plates And Mono Plates In Hydrogen Energy Systems

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | Hydrogen Energy Systems Titanium Bipolar Plates,Mono Plates Titanium Bipolar Plates,Hydrogen Energy Systems Mono Plates |

||

|---|---|---|---|

As the global energy structure transitions toward low-carbon and renewable sources, hydrogen energy is emerging as a critical zero-emission energy carrier. Titanium-based bipolar plates and mono plates are becoming key components for efficient and safe hydrogen energy systems.

Titanium Bipolar Plates and Mono Plates: Core Components of Hydrogen Systems

In hydrogen electrolysis, fuel cells, and hydrogen processing equipment, bipolar and mono plates play multiple essential roles, including current collection, gas distribution, heat management, and sealing. Titanium, with its excellent corrosion resistance, high strength, lightweight, and outstanding electrochemical stability, has become the material of choice for high-performance hydrogen equipment, particularly suitable for PEM (Proton Exchange Membrane) and AEM (Anion Exchange Membrane) electrolyzers.

Technical Advantages

-

Outstanding Corrosion Resistance

Titanium forms a dense and stable oxide layer in strong acid, alkali, and chlorine-containing environments, significantly extending the service life of the plates and reducing maintenance costs. -

Low Contact Resistance

Advanced surface treatment processes, such as conductive coatings or noble metal surface modifications, effectively reduce contact resistance and improve overall system efficiency. -

Integrated Design Capability

Mono plates are designed with integrated gas channels, cooling channels, and sealing structures using precision machining, enhancing system compactness and reliability.

Engineering Integration and Manufacturing Technology

Systems utilizing titanium bipolar and mono plates can achieve high-efficiency electrolysis, low energy consumption, and long service life. Key engineering capabilities include:

-

3D Modeling and Simulation Optimization

Using CAD/CAE tools to simulate gas flow channels, current density distribution, stress, and thermal management, ensuring rational design and stable performance of the plates. -

Multi-material and Composite Technology Integration

Offering multiple technical routes, including titanium alloys, composite coatings, and noble metal surface modifications, to meet various performance requirements of hydrogen systems. -

Modular System Design

Supporting modular integration for large-scale hydrogen systems, reducing overall system complexity.

Future Outlook

The application of titanium bipolar and mono plates is driving the hydrogen energy industry toward higher efficiency, longer service life, and lower maintenance. This technology is expected to be widely used in PEM electrolysis, AEM electrolysis, fuel cell stacks, and hydrogen distribution systems, becoming a key enabling technology for the advancement of the green hydrogen economy.