-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

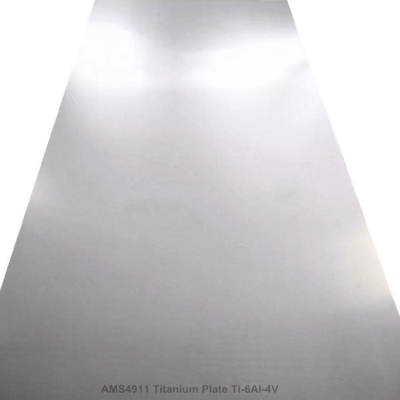

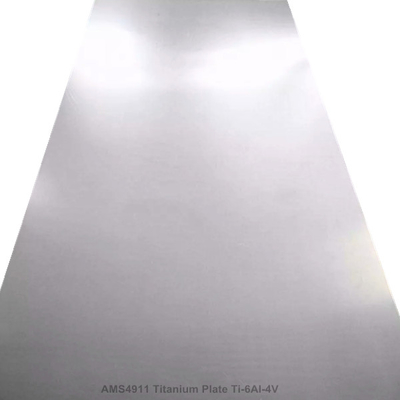

AMS 4911 Ti6AL-4V Titanium Alloy Sheet THK1.0mm For Aerospace

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Standard | AMS 4911 Titanium Alloy Sheet | Material | Ti6AL-4V |

|---|---|---|---|

| Surface | Surface | Thickness | 1.0mm |

| CERTIFICATION | ISO 9001 | Application | Aerospace |

| Highlight | AMS 4911 Titanium Alloy Sheet,Aerospace Titanium Alloy Sheet,THK1.0mm Titanium Alloy Sheet |

||

AMS 4911 Ti6AL-4V Titanium alloy sheet THK1.0mm for aerospace.

AMS 4911 Titanium Alloy, Sheet, Strip, and Plate 6AI-4V Annealed (Composition similar to UNS R56400)

This specification covers a titanium alloy in the form ofsheet, strip, and plate up through 4.000 inches (101.60 mm) inclusive

in thickness.

Application: These products have been used typically for parts requiring strength up to 750 °F (399 °C), but usage is not limited to such applications.

Composition(%)

| Element. | Aluminum | Vanadium | Iron | Oxygen | Carbon | Nitrogen | Hydrogen | Titanium | Other, each |

| Min | 5.50 | 3.50 | ---- | ---- | ---- | ---- | ---- | ---- | ---- |

| Max | 6.75 | 4.50 | 0.30 | 0.20 | 0.08 | 0.05 | 0.015 | remainder | ≤0.10,≤0.4 |

determined in accordance with ASTM E8/E8M with the rate of strain set at0.005 in/in/min (0.005 mm/mm/min) and maintained within a tolerance of±0.002in/in/min(0.002 mm/mm/min) through the 0.2% offset yield strain.

| Nominal Thkciknee (mm) | Tensile Strength MPa | Yield Strength at 0.2% MPa | Elongation in50.8mm or 4D% |

| 0.63~1.6 | 920 | 869 | 8 |

![]()

Annealing

The product shall be annealed by heating to a temperature within the range 1300 to 1650 °F (704 to 899 °C), holding at the

selected temperature within ±25 F (±14 °℃) for a time commensurate with product thickness and the heating equipment

and procedure used, and cooling at a rate which will produce product meeting the requirements of 3.5. Pyrometry shall be

in accordance with AMS2750.

Properties

The product shall conform to the following requirements and also shall meet the requirements of 3.5.1 and 3.5.2 after being

reheated in air to 1325 F ± 15 ℉ (718 °℃ ± 8 °C), held at heat for 20minutes ± 2 minutes, cooled at a rate equivalent to

an air cool or slower.

Packing: Standard Export seaworthy packing,wooden pallet,wooden case,suit for all transports or packaging as your request Port:

Tianjin.Qingdao. Shanghai. Beijing.Shenzhen Guangdong or Any port in china

Delivery:7-30 days from the date of receiving the deposit

♦We can airmail samples in the shortest time according to your requirements

♦We promise that we will reply you in time

♦We promise that we will complement your order on time

♦We are sure that you will be satisfied with both our products and services

* In the year 2001, set up the forging workshop.

* In 2006, registered for Changsheng Titanium Co.

* In 2008, started the global business, established Changtai Metals Trading Co.

* In 2008, worked with alibaba.com, and to be the golden supplier of alibaba.

* In 2010, researched and developed the technology of big seamless titanium tube.

* In 2012, finished the trial production of big seamless titanium tube sucessfully, and applied for the national patent.

* In 2013, made mass production of big seamless titaniumtube.

* In 2014, developed the technology of Grade 5 tube, introduced Germany production equipment.

* In 2014, enlarged the production line of customized parts, made titanium radiators and heat exchangers for Canada Saltswork and American Ural Company.

* In 2015, finished the trial production of Grade 5 tubes, and started to make mass production.

* In 2016, set up foreign sales team in Xi'an City.

* In 2017, enlarged the production of tube.

* In 2018, enlarged the production of plate and anode.

* In 2019, we focus on India market, plan to attend two exhibitions India in September & November.