-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

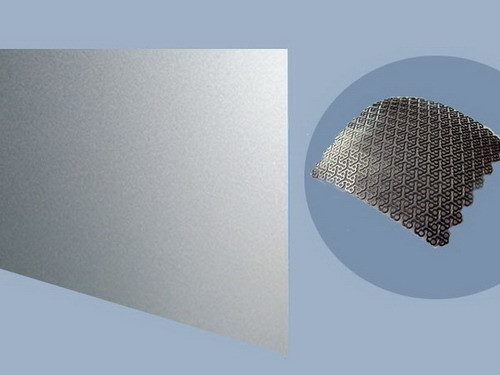

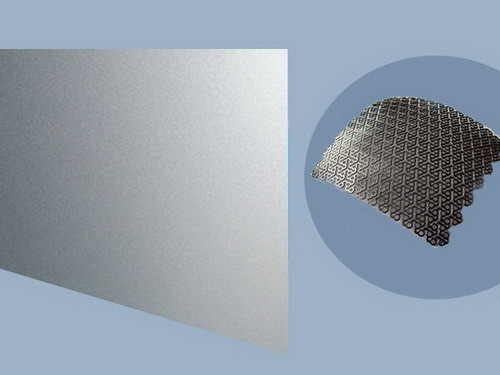

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

factory ASTM F1472 (UNS R56400) GR5 Titanium alloy sheet for medical

| Place of Origin | China Baoji |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001 |

| Model Number | CSTY-PL |

| Minimum Order Quantity | 10kg |

| Price | 10-1000USDper kg |

| Packaging Details | Caroton Boxes or Export Wood Case Or As Client Requried |

| Delivery Time | 15-30days |

| Payment Terms | T/T, L/C or Negotiation |

| Supply Ability | 30Tons per month |

| Standard | UNSR56400 | Material | Ti 6al4v |

|---|---|---|---|

| Application | Medical . Surgical Implants | Others Name | Titanium Plate,titanium Sheet |

| Highlight | ASTM F1472 Titanium Alloy Plate,gr5 Titanium Alloy Plate,UNS R56400 titanium sheet metal |

||

GR5 Medical Titanium Alloy Sheet Titanium Plate ASTM F1472 (UNS R56400)

ASTM F1472 standard,Manufacturing requirements:

Finish—The mill product may be furnished to the purchaser as mechanically descaled or pickled, sandblasted, chemically milled, ground, machined, peeled, polished, combinations of these operations, or as specified by the purchaser. On billets, bars, plates, and forgings, it is permissible to remove minor surface imperfections by grinding if the resultant area meets the dimensional and surface finish requirements of this specification. Condition—Material shall be furnished in the annealed or cold-worked condition.

This standard have special requirements of microstructure:

1. The microstructure shall be a fine dispersion of the alpha and beta phases resulting from processing in the alpha plus beta field. There shall be no continuous alpha network at prior beta grain boundaries. There shall be no coarse, elongated alpha platelets.

2. Determine the beta transus temperature for each heat by a suitable method and report on the material certification if required by the purchaser.

3. Alpha case is not permitted for products supplied with a machined, ground, or chemically milled surface finish. For other products, there will be no continuous layer of alpha case when examined at 100* magnification.

Chemical Composition

| Element | Composition % |

| Nitrogen, max | 0.05 |

| Carbon, max | 0.08 |

| Hydrogen, max | 0.015 |

| Iron, max | 0.30 |

| Oxygen, max | 0.20 |

| Aluminum | 5.5~6.75 |

| Vanadium | 3.5~4.5 |

| Yttrium | 0.005 |

| Titamium | balance |

Mechanical Properties

| Size | Tensile strength/ Mpa | Yield strength/ Mpa |

| bars, forgings | ||

| up to 50mm | 930 | 860 |

| over 50mm to 150mm | 895 | 825 |

| sheet, strip and plate | ||

| up to 4.8mm | 924 | 869 |

| 4.8-101.6mm | 895 | 825 |

Tag:gr5 medical titanium plate ,manufacturers ,factory,titanium alloy,titanium alloy sheet