-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

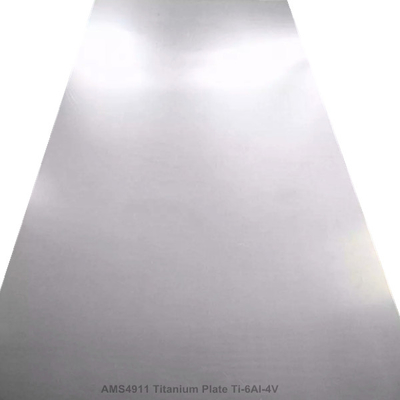

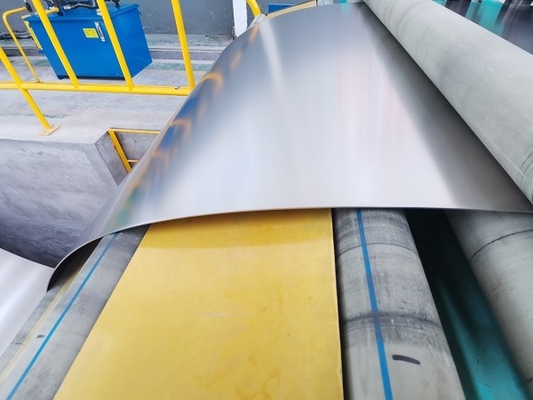

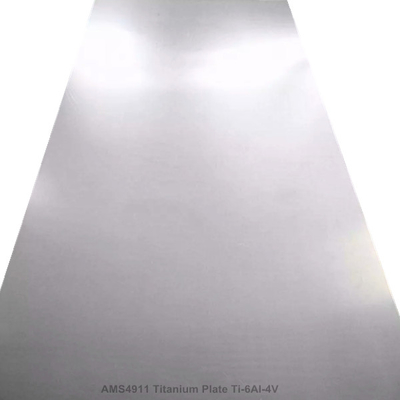

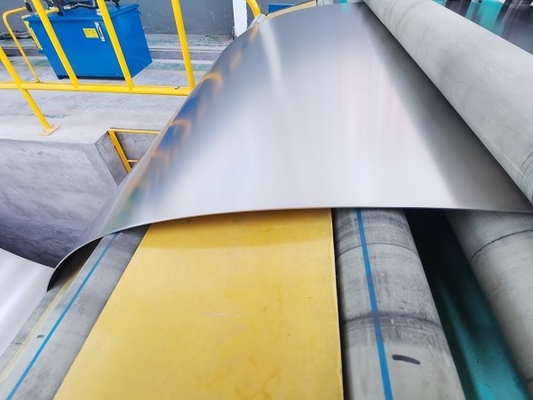

AMS 4911 Ti6AL-4V Titanium Alloy Sheet THK0.635mm For Aerospace

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Ti6AL-4V GRADE 5 | Standard | AMS 4911 Titanium Alloy Sheet |

|---|---|---|---|

| Technique | Cold Rolled | Surface | Smooth |

| Thickness | 0.635mm | PAYMENT | T/T/LC At Sight |

| CERTIFICATION | ISO 9001 | Application | Aerospace |

| Highlight | THK0.635mm Titanium alloy sheet,aerospace Titanium alloy sheet,AMS 4911 Titanium alloy sheet |

||

AMS 4911 Ti6AL-4V Titanium alloy sheet THK0.635mm for aerospace.

AMS 4911 Titanium Alloy, Sheet, Strip, and Plate 6AI-4V Annealed (Composition similar to UNS R56400)

This specification covers a titanium alloy in the form ofsheet, strip, and plate up through 4.000 inches (101.60 mm) inclusive

in thickness.

Application: These products have been used typically for parts requiring strength up to 750 °F (399 °C), but usage is not limited to such applications.

Composition(%)

| Element. | Aluminum | Vanadium | Iron | Oxygen | Carbon | Nitrogen | Hydrogen | Titanium | Other, each |

| Min | 5.50 | 3.50 | ---- | ---- | ---- | ---- | ---- | ---- | ---- |

| Max | 6.75 | 4.50 | 0.30 | 0.20 | 0.08 | 0.05 | 0.015 | remainder | ≤0.10,≤0.4 |

determined in accordance with ASTM E8/E8M with the rate of strain set at0.005 in/in/min (0.005 mm/mm/min) and maintained within a tolerance of±0.002in/in/min(0.002 mm/mm/min) through the 0.2% offset yield strain.

| Nominal Thkciknee (mm) | Tensile Strength MPa | Yield Strength at 0.2% MPa | Elongation in50.8mm or 4D% |

| 0.63~1.6 | 920 | 869 | 8 |

![]()

♦We can airmail samples in the shortest time according to your requirements

♦We promise that we will reply you in time

♦We promise that we will complement your order on time

♦We are sure that you will be satisfied with both our products and services

* In the year 2001, set up the forging workshop.

* In 2006, registered for Changsheng Titanium Co.

* In 2008, started the global business, established Changtai Metals Trading Co.

* In 2008, worked with alibaba.com, and to be the golden supplier of alibaba.

* In 2010, researched and developed the technology of big seamless titanium tube.

* In 2012, finished the trial production of big seamless titanium tube sucessfully, and applied for the national patent.

* In 2013, made mass production of big seamless titaniumtube.

* In 2014, developed the technology of Grade 5 tube, introduced Germany production equipment.

* In 2014, enlarged the production line of customized parts, made titanium radiators and heat exchangers for Canada Saltswork and American Ural Company.

* In 2015, finished the trial production of Grade 5 tubes, and started to make mass production.

* In 2016, set up foreign sales team in Xi'an City.

* In 2017, enlarged the production of tube.

* In 2018, enlarged the production of plate and anode.

* In 2019, we focus on India market, plan to attend two exhibitions India in September & November.

Tianjin.Qingdao. Shanghai. Beijing.Shenzhen Guangdong or Any port in china

Delivery:7-10 days from the date of receiving the deposit