-

Titanium Pipe Fittings

-

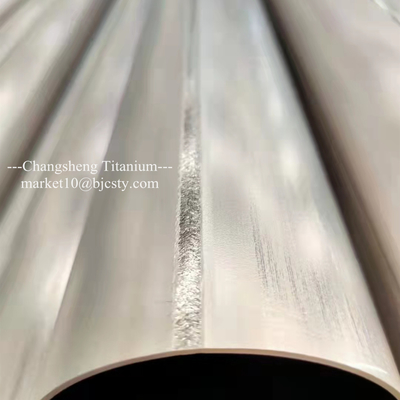

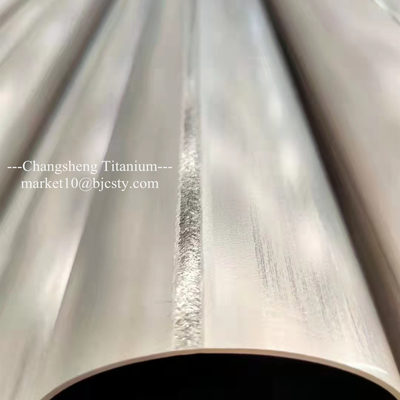

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Titanium Welded Pipe Wet Chlorine Pipeline Brine Electrolysis Piping Material

| Place of Origin | Baoji City, China |

|---|---|

| Brand Name | Changsheng |

| Certification | ISO9001:2015 |

| Model Number | Titanium Pipe Pipeline |

| Minimum Order Quantity | 100kg |

| Price | USD 16.0/KG - USD 18.0/KG |

| Packaging Details | Soft film wrapped inside, export standard crate outside. |

| Delivery Time | 20-25 work days |

| Payment Terms | L/C, T/T |

| Supply Ability | 60 Tons per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Titanium Pipe And Titanium Tube | Materials | Pure Titanium In Gr.2, Gr.12 |

|---|---|---|---|

| Standards | ASTM B861 ASTM B862 | Keywords | Brine Electrolysis,Wet Chlorine Pipeline, Chlorine Alkali Industry, Anti-corrosion |

| Max. Diameter | OD2300mm | Surface | Acid Washing Surface/Sandblasting Surface |

| Application | Wet Chlorine Gas Cooler, Heat Exchangers, Pressure Vessels, Pipe Spools | Other Material | Titanium In Gr1 And Gr7 |

| Factory Certificate | ISO 9001:2015 | ||

| Highlight | Pipeline Titanium Welded Pipe,Wet Chlorine Pipeline Titanium Welded Pipe |

||

Titanium Welded Pipe Wet Chlorine Pipeline Brine Electrolysis Piping Material

We manufacture welded pipes in the following materials: Titanium Gr1 Gr2 Gr12

Testing: Ultrasonic test, Eddy current inspection, Hydraulic test

Processing: welding(MIG, automatic arc-welding process or other method of welding)

Reasons for Using Titanium Piping Material When Transport Wet Chlorine Gas

The degree of corrosion of wet chlorine gas is very high, which is easy to cause corrosion leakage of equipment and pipelines. The use of graphite, glass tube, ceramic, plastic coolers, etc., there are many problems such as poor corrosion resistance, easy to break, easy to age, and stainless steel coolers can only be used for 8 to 10 days on the need to stop for repair. The test results show that titanium is extremely resistant to corrosion in the environment of high temperature wet chlorine gas, and the annual corrosion amount is 0.0025mm. The use of titanium coolers and titanium pipes in chlor-alkali industrial production can shorten the cooling and drying process, reduce the loss of chlorine gas, reduce environmental pollution, and create conditions for stable operation of compressed gas and achieve a high degree of drying.

Titanium Welded Pipes Features:

1. High strength: Titanium welded pipes have extremely high strength and toughness, and can withstand pressure and impact in extreme environments.

2. Corrosion resistance: Titanium welded pipes have excellent corrosion resistance and can be used in a variety of harsh environments.

4. Lightweight: Titanium welded pipes have a lower density and strength ratio, which can reduce the weight of the entire structure.

Titanium Welded Pipes Mechanical Properties:

| ASTM Grade | Alloy composition | Tensile strength | Yield strength | Elongation % | ||

| ksi | Mpa | ksi | Mpa | |||

| GR1 | Unalloyed Ti(Pure)35A-CP1 | 35 | 240 | 25 | 170 | 24 |

| GR2 | Unalloyed Ti(Pure)50A-CP2 | 50 | 345 | 40 | 275 | 20 |

| GR12 | Ti-0.3Mo-0.8Ni | 70 | 483 | 50 | 345 | 18 |