-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

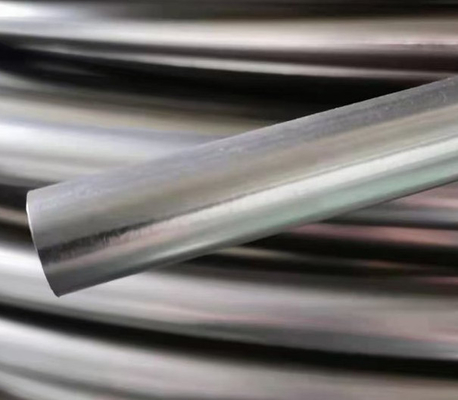

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

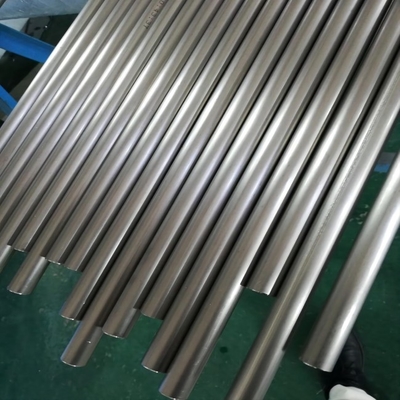

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

0.75" 1.5" 2in Gr1 welding titanium pipe for Heat Exchangers and Pressure Vessels

| OD | 6-1530mm | Wall Thickness | 0.35-8.00mm |

|---|---|---|---|

| Quanlty Control | 100% Inspection | Material | Gr1 Gr2 Welding Titanium Exhaust Pipes |

| Surface | Acid Picking | Advantage | Low Price,Anti-Corrosion |

| Highlight | 1.5" titanium round tube,2in titanium round tube,Gr1 1 inch titanium tube |

||

| OD | 6-1530mm | |

|---|---|---|

| Wall thicknes | 0.35-8.00mm | |

| Quanlty Control | 100% Inspection | |

| Material | titanium welded pipeGr1 Gr2 | |

| type | round | |

| surface | Smooth | |

| Length Range | < 15000 mm | |

| Standard | ASTM B338,ASTM B862 | |

| Technique | welded | |

| Application | Heat Exchangers and Pressure Vessels | |

| Advantage | titanium pipe welding factory |

OD 0.75" 1" 1.5" 2" weld titanium exhaust pipes for Heat Exchangers and Pressure Vessels

|

Standard

|

ASTM B862, ASTM B338

|

|

Material

|

GR1 GR2 Gr5 (6AL4V) GR7 GR9

|

|

Size

|

Diameter: 3.0mm ~120mm Wall thickness: 0.5- 8mm Or As drawings |

|

Type

|

Round, square, coiling

|

|

Goods Condition

|

M

|

|

Surface

|

Sand blast

|

|

Test

|

Water pressure test, Ultrasonic test, X-ray test, Eddy current test,Flaring and Flattening test.

|

|

Package Method

|

Wooden case, and Customer requirements

|

|

Payment way

|

T/T, L/C, WesternUnion, Paypal, can be negotitated.

|

|

Transportation

|

Sea(FCL/LCL), airplane, express(TNT/DHL/FEDEX)

|

|

Port

|

Shanghai,Tianjin,Qingdao

|

|

Certificate

|

EN10204 3.1/3.2 as required.

|

|

Applications

|

Shell and tube heat exchanger, condenser, evaporator, pipeline, etc Seawater desalination equipment

Bike rack

Marine pressure tube

Oil drilling pressure tube

|

![]()

![]()

We are titanium company from China, from 2001,have more than 20years experience.We are a professional manufacturer and exporter of titanium tube.

FAQ

1. Are you the manufacturing or trading company?

Real manufacturing company, started from 2001, nearly 20 years. With 2 sales teams for foreign trading business, started from 2008, more than 10 years experiences.

2. Do you have a dedicated R & D team? Can you design a product for us?

We have a dedicated technical team responsible for research and development. But most of titanium fittings are standard, we can follow ASTM or other you asked.

3. Can you provide samples? Is there a charge?

Samples can be provided for a fee.

4. What is your payment method?

We can accept T / T, LC, trade assurance order from alibaba.com. Samples are 100% prepaid. Orders for mass production are below 1000 USD, 100% prepaid, above 1000 USD, 30% prepaid, and 70% paid before delivery.

5. How long is your delivery time?

Inventory samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances.

6. After-sales products, how to deal with problems?

Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem:

1) Among the products that have problems, 93% are misplaced in pre-sales communication, and the product that the customer needs is not really clear.

2) 5% is an unexpected situation and the extension of the construction period.

3) 2% is the problem of transportation and packaging. During long-distance transportation, the packaging is damaged and the surface is damaged.

7. What is your company's response to the product in question?

1) Verify and blame for pre-sales communication issues. Compensation is handled according to the proportion of liability.

2) We are 100% responsible for problems caused by damaged packaging during transportation.