-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

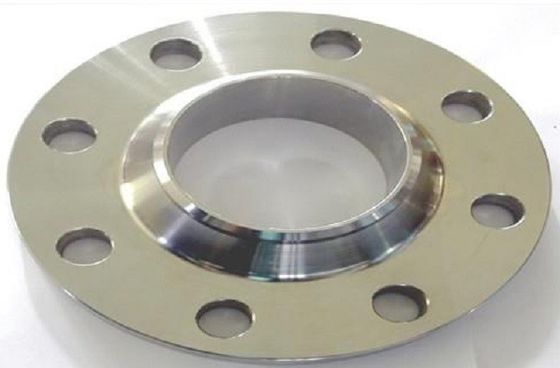

GR12 Titanium WNRF Flange 6 INCH Forged Flange Gr5 Oil Welding Sprint Car

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001:2015 |

| Minimum Order Quantity | 10kgs |

| Price | $110.00 - $150.00/ Piece |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Features | High Strength, Corrosion Resistance, Lightweight, Low Thermal Expansion | Technique | Forged, Welded |

|---|---|---|---|

| Production Standards | ANSI B16.5, ASME B16.47, DIN 2566. | Key Words | Titanium GR1 GR2 Lap Joint Flange |

| Standard | ASME B16.5, ASME B16.47, MSS SP-44, API, DIN, JIS, BS, Etc. | Connection Type | Weld Neck, Slip On, Socket Weld, Threaded, Blind |

| Application | Chemical, Petrochemical, Oil & Gas, Power Generation, Etc. | Flange Surface | FF,RF,TG,RJ Etc |

| Quality Control | Professional Inspection | Pressure | Class150-2500, PN6-PN600 |

| Processing | CNC Machining, Forging, Casting, Etc. | Service | OEM ODM |

| Pressure Rating | Class 150 - Class 2500 | Material | Titanium |

| Standards | ASME B16.5, ASME B16.47, MSS SP-44 | ||

| Highlight | Titanium WNRF Flange,Titanium 6 INCH Forged Flange |

||

Description

A titanium flange is a connecting component made from non-ferrous titanium or titanium alloy. It features outstanding corrosion resistance, acid and alkali resistance, long service life, and a smooth surface that resists contamination. Titanium flanges are widely used in various industrial applications requiring durability and reliability under harsh environments.

Specification

| Product Name | Titanium Flange |

|---|---|

| Material | Pure Titanium and Titanium Alloys (Gr1, Gr2, Gr5, Gr7, Gr9, Gr12, etc.)Also available in Pure Nickel, Inconel Alloy, Zirconium & Zirconium Alloy, Monel, Hastelloy, and Incoloy Alloy |

| Standard | ANSI B16.5, ASTM B16.5, ASME B16.47, JIS B2220, DIN 2627–2628, AWWA, ASTM A182, ASME SA182 |

| Dimension | 1/2"–60" NB (NPS 1/2–NPS 24, DN 10–2000) |

| Pressure Class | PN0.25–32 MPa(DIN: PN6, PN10, PN16, PN25 to PN250)150#, 250#, 300#, 400#, 500#, 600#, 900#, 1500#, 2500# |

| Flange Surface | FF, RF, TG, RJ, MFM |

| Special Features | Corrosion Resistance, High Pressure Resistance |

| Application | Chemical, Petroleum, Machinery, Marine, and Industrial Equipment |

Advantages

-

Low density and high specific strength

-

Excellent corrosion resistance in acids, alkalis, and seawater

-

High heat resistance and good thermal performance

-

Outstanding performance in low-temperature environments

-

Non-magnetic and non-toxic

-

Excellent mechanical strength and pressure resistance

-

Low elastic modulus and good weldability

Applications

-

Mechanical and chemical equipment

-

Electroplating systems

-

Medical and pharmaceutical devices

-

Precision components and industrial machinery

-

Aerospace applications – aircraft engine compressor parts

-

Defence applications – rockets, missiles, and high-speed aircraft structures