-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

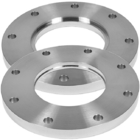

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

PL 1500 GR1 GR2 Titanium Lap Joint Flanges 60" ASME B16.5 piping stub end

| Place of Origin | China |

|---|---|

| Brand Name | CSTY2022 |

| Certification | ISO9001 |

| Model Number | PL Welding plate flange |

| Minimum Order Quantity | 1 Piece |

| Price | $50.00 - $1,000.00/ Piece |

| Packaging Details | Export wooden box package with metal binding to ensure the shipping safe and your suggestion welcome. |

| Delivery Time | 7~14 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 2000 Pieces per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Grade | Titanium Gr1, Gr2,Gr5, Gr12 | Product Name | PL 1500 GR1 GR2 Titanium Lap Joint Flanges 60" ASME B16.5 Piping Stub End |

|---|---|---|---|

| Key Words | Titanium GR1 GR2 Lap Joint Flange | Size | 1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

| Pressure | Class150~2500 | Surface | Polished, Acid Pickled, Bright Finish |

| Application | Chemical Processing,Oil And Gas,Marine Applications,Aerospace Industry,Medical Equipment,Power Generation,Automotive And Racing Industry | Technique | Forged, Welded |

| Highlight | 60" Titanium Lap Joint Flanges,GR2 Titanium Lap Joint Flanges,ASME B16.5 lap joint pipe flanges |

||

PL 1500 GR1 GR2 Titanium Lap Joint Flanges 60" ASME B16.5 piping stub end

Titanium Lap Joint Flanges are a type of flange used in piping systems that require easy assembly and disassembly of the piping components. The Lap Joint Flange consists of two parts: a stub end and a backing flange. The stub end is welded to the pipe, while the backing flange is bolted to the flange of the adjoining pipe. The backing flange can be made of a different material than the stub end, providing flexibility in material selection for different applications.

Titanium is a corrosion-resistant material that offers high strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures. These properties make it an ideal material for use in piping systems in industries such as aerospace, chemical processing, and marine.

The pressure rating of 1500 PSI indicates that this type of Lap Joint Flange can withstand a maximum pressure of 1500 PSI before experiencing failure. The size of 60 inches in diameter suggests that this type of Lap Joint Flange is suitable for use in large diameter piping systems.

Specification of Lap Joint flanges

|

products |

Lap Joint flanges |

|

Material Grade |

Gr1 Gr2 Gr3 Gr4 GR5 Gr7 Gr9 Gr11 |

|

Certification |

ISO9001:2008 Alibaba.com Assessed Supplier |

|

Standard |

ANSI B16.5 ASTM B16.5 ASME B16.47 JIS B2220 DIN2627-2628 |

|

size |

1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

|

Pressure Class |

PN0.25~32Mpa |

|

(DIN) PN6 PN10 PN16 PN25 though PN250 |

|

|

150# 250# 300# 400# 500# 600# 900# 1500# 2500# |

|

|

Technique |

Forged and CNC Machined |

|

Flange surface |

FF RF TG RJ MFM |

Types of Flanges

Flange is a mechanical component used to connect two pipes or other equipment together. There are several types of flanges used in piping systems, each designed for a specific application. Here are some of the most common types of flanges:

1.Weld Neck Flange: This type of flange is attached to the pipe by welding and has a long tapered hub that provides reinforcement to the connection. Weld Neck Flanges are commonly used in high-pressure applications.

2.Slip-On Flange: This type of flange slides over the end of the pipe and is then welded in place. Slip-On Flanges are easier to align and install than other types of flanges, but they are not as strong and are not recommended for high-pressure applications.

3.Blind Flange: This type of flange is used to close off the end of a piping system. Blind Flanges are commonly used in situations where future expansion of the system is expected.

4.Socket Weld Flange: This type of flange is similar to the Slip-On Flange, but it has a recessed area that allows the pipe to be inserted and then welded in place.

5.Lap Joint Flange: This type of flange consists of two parts: a stub end and a backing flange. The stub end is welded to the pipe, while the backing flange is bolted to the flange of the adjoining pipe. Lap Joint Flanges are commonly used in situations where frequent dismantling and assembly of the piping system is required.

These are just a few of the many types of flanges available, each with its own unique design and application. The choice of flange type depends on various factors such as the operating conditions, pressure, temperature, and material of the piping system.

![]()

Application Case of Titanium Lap Joint Flanges

Titanium lap joint flanges are commonly used in various industries where corrosion resistance, high strength, and lightweight properties are required. Here are some application cases where titanium lap joint flanges are utilized:

1. Chemical Processing: Titanium lap joint flanges are widely used in chemical processing industries due to their excellent corrosion resistance properties. They are suitable for handling corrosive chemicals, acids, and other aggressive substances. These flanges ensure a leak-free connection and provide long-term durability, making them ideal for pipelines, reactors, and storage tanks in chemical plants.

2. Oil and Gas: The oil and gas industry often deals with challenging environments, including high temperatures and corrosive fluids. Titanium lap joint flanges are used in offshore platforms, refineries, and pipelines where resistance to seawater, crude oil, and other hydrocarbons is essential. They offer reliable connections for critical components like valves, pumps, and heat exchangers.

3. Marine Applications: Titanium lap joint flanges find extensive use in marine applications, such as shipbuilding and offshore structures. These flanges provide excellent resistance to saltwater corrosion, which is crucial in marine environments. They are employed in seawater cooling systems, desalination plants, and various marine piping systems.

4. Aerospace Industry: Titanium lap joint flanges are preferred in the aerospace industry due to their lightweight nature and high strength-to-weight ratio. They are used in aircraft and spacecraft applications, including fuel systems, hydraulic systems, and engine components. The use of titanium flanges helps reduce the overall weight of the aircraft, leading to improved fuel efficiency.

5. Medical Equipment: Titanium is biocompatible, non-toxic, and resistant to bodily fluids, making it suitable for medical applications. Lap joint flanges made from titanium are used in medical equipment, such as surgical instruments, implants, and prosthetics. These flanges ensure a secure connection and long-term reliability in critical medical devices.

6. Power Generation: Titanium lap joint flanges are utilized in power generation facilities, especially those using seawater or corrosive cooling systems. They are employed in power plants, desalination plants, and nuclear facilities where resistance to corrosion and high temperatures is required. These flanges provide a reliable connection for pipes, valves, and heat exchangers in such demanding environments.

7. Automotive and Racing Industry: Titanium lap joint flanges find application in the automotive and racing industry, particularly in high-performance vehicles. They are used in exhaust systems, turbochargers, and intercoolers due to their lightweight and heat-resistant properties. Titanium flanges contribute to improved performance and durability under extreme conditions.

These are just a few examples of the application cases for titanium lap joint flanges. Their unique combination of properties makes them valuable in industries where corrosion resistance, strength, and weight reduction are critical factors.

Tag: titanium Lap Joint Flange,titanium pipe blind flange, titanium piping