-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

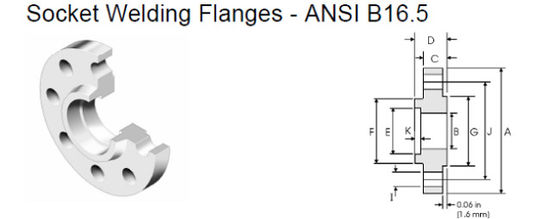

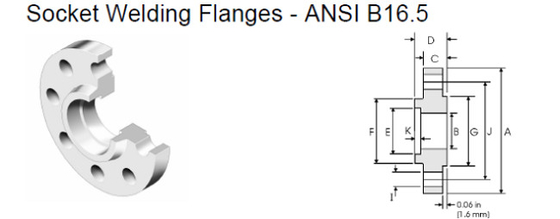

Pure Gr7 Gr9 Gr11 Titanium Socket Weld Flange ANSI B16.5 connect pipes valves

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | Socket welding flange |

| Minimum Order Quantity | 1 Piece |

| Price | $25.00 - $40.00/ Piece |

| Packaging Details | Export wooden box package with metal binding to ensure the shipping safe and your suggestion welcome. |

| Delivery Time | 7~14 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 2000 Pieces per Month |

| Grade | Gr2, Gr1, Titanium, Gr4, Gr3 | Product Name | ASME B16.5 ANSI B16.5 Titanium GR1 GR2 PL Welding Plate Flange High Quality Best Price |

|---|---|---|---|

| Key Words | Titanium GR1 GR2 Socket Welding Flange | Color | Sliver, Titanium Original Color, Ti Natural |

| Surface | Polished, Acid Pickled, Bright Finish | Application | Industrial, Heat Exchanger, Medical, Auto Exhaust, Industry/medical |

| Technique | Forged, Welded | Material | Pure Titanium, GR1, GR2 |

| Highlight | Gr11 Titanium Socket Weld Flange,ANSI B16.5 Titanium Socket Weld Flange,Gr7 titanium socket welding flange |

||

Gr1,Gr2,Gr3,Gr4,GR5,Gr7,Gr9,Gr11 Socket welding flange ANSI B16.5/ASTM B16.5

Titanium socket weld flange is a type of flange that is used to connect pipes, valves, and other equipment to a piping system. It is made of titanium, a strong and lightweight metal that is resistant to corrosion, making it ideal for use in harsh environments.

Socket weld flanges have a recessed area in the center, which is used to insert the pipe or equipment being connected. The flange is then welded to the pipe or equipment using a socket weld, which is a type of weld where the pipe is inserted into the socket of the flange and welded from the outside. This creates a strong, leak-free connection between the two pieces of equipment.

products |

SOCKET WELDING |

Material Grade |

Gr1 Gr2 Gr3 Gr4 GR5 Gr7 Gr9 Gr11 |

Certification |

ISO9001:2008 Alibaba.com Assessed Supplier |

Standard |

ANSI B16.5 ASTM B16.5 ASME B16.47 JIS B2220 DIN2627-2628

|

size |

1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

Pressure Class |

PN0.25~32Mpa |

(DIN) PN6 PN10 PN16 PN25 though PN250 |

|

150# 250# 300# 400# 500# 600# 900# 1500# 2500# |

|

Technique |

Forged and CNC Machined |

type |

Weldnecks Slip-Ons Threaded Blind Socketweld and Lap-Joint |

Flange surface |

FF RF TG RJ MFM |

2. Relevant Parameters

Titanium ANSI Flange

The oil, gas, and petrochemical industries use many different types of titanium flanges, with each type used in specific situations in order to maximize the life of the flange, ease of installation, and overall cost.

![]()

Weld neck flanges

The weld flange is the standard against which all other ANSI flanges are measured when it comes to strength and wear life. Long weld neck flanges are the standard because they are used for many different high-pressure applications at a variety of extreme temperatures and are designed to limit turbulence and erosion at the joint.

![]()

Slip-On Flanges

In general, these flanges are rated at about two-thirds of the strength of a standard long weld neck flange and they have a fatigue life of about one-third of that of a comparable long-weld neck flange. They are connected to pipes using two filet welds, one at the outside of the flange and another at the inside of the flange. This makes them a bit more time consuming to install on a pipe, as well as reduces the versatility of the flange because combining them with elbow and tees is not possible. All fittings used with slip-on flanges must have a straight end.

![]()

Blind Flanges

Blind pipe flanges seal off pipes, valves, and ASME pressure vessel openings while providing an option to expand the pipeline network in the future. These flanges are also often used for high-pressure testing within the pipeline network.

![]()

Socket Weld Flanges

Socket weld flanges are just about as strong as slip on flanges, but are about 50% stronger when it comes to resisting fatigue. These flanges are attached using a single fillet weld on the outside of the flange. This makes them less labor intensive to install.

![]()

Threaded Flanges

The best thing about threaded flanges is that they can be installed into a pipe system without welding. These are used for smaller pipe sizes most of the time and only for pipe systems that have thick walls.

3. Type of flange

![]()

Titanium socket weld flanges are commonly used in applications where high strength and corrosion resistance are required, such as in the chemical, oil and gas, and marine industries. They are also used in applications where weight is a concern, such as in aerospace and automotive industries.

It is important to ensure that the titanium socket weld flange is compatible with the materials being connected, and that the welding process is performed correctly to prevent leaks and ensure a strong connection.

Tag: Weldnecks Slip-Ons, Threaded Blind, Socketweld and Lap-Joint