-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

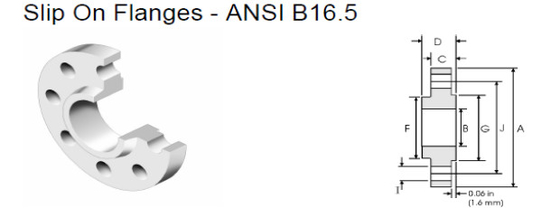

PN0.25 Gr4 Titanium Pipe Flange , ANSI B16.5 Titanium Slip On Pipe Flange

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | titanium Slip-On Flange |

| Minimum Order Quantity | 1pc |

| Price | $30.00~$45.00/kg |

| Packaging Details | Export wooden box package with metal binding to ensure the shipping safe and your suggestion welcome. |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 2000 Pieces per Month |

| Standard | ANSI B16.5 ASTM B16.5 ASME B16.47 JIS B2220 DIN2627-2628 | Size | 1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

|---|---|---|---|

| Shape | Slip-On Flange | Pressure Class | PN0.25~32Mpa |

| Grade | Gr1 Gr2 Gr3 Gr4 GR5 Gr7 Gr9 Gr11 Titanium | Application | Industrial, Heat Exchanger, Medical, Auto Exhaust, Industry/medical |

| Color | Sliver, Titanium Original Color, Ti Natural, Grey | Technique | Forged And CNC Machined |

| Highlight | PN0.25 Titanium Pipe Flange,Gr4 Titanium Pipe Flange,ANSI B16.5 titanium slip on pipe flange |

||

Description of Titanium Slip On Pipe Flange

Titanium slip-on pipe flange is a type of flange used to connect pipes or tubes of different diameters.The slip-on flange is designed to slip over the end of the pipe or tube and is then welded in place to create a secure and leak-free joint.

The flange has a circular shape and a flat face with bolt holes around the perimeter. The bolt holes are used to connect the flange to the mating flange or equipment by bolts. The slip-on flange is typically used in applications where easy assembly and disassembly is required, such as in pipelines, chemical plants, and oil refineries.

Titanium slip-on pipe flanges are commonly used in high-temperature and corrosive environments where other materials may fail. They are also used in industries such as aerospace, medical, and marine due to their high strength-to-weight ratio and corrosion resistance. The titanium slip-on pipe flange is available in various sizes and can be customized to meet specific requirements

Specification of Titanium Slip On Pipe Flange

| products |

Slip-On Flange |

| Material Grade |

Gr1 Gr2 Gr3 Gr4 GR5 Gr7 Gr9 Gr11 |

| Certification |

ISO9001:2008 Alibaba.com Assessed Supplier |

| Standard |

ANSI B16.5 ASTM B16.5 ASME B16.47 JIS B2220 DIN2627-2628 |

| size |

1/2"~ 60"NB NPS 1/2 - NPS 24 (DN 10 - 2000) |

| Pressure Class |

PN0.25~32Mpa |

|

(DIN) PN6 PN10 PN16 PN25 though PN250 |

|

|

150# 250# 300# 400# 500# 600# 900# 1500# 2500# |

|

| Technique |

Forged and CNC Machined |

| type |

Weldnecks Slip-Ons Threaded Blind Socketweld and Lap-Joint |

| Flange surface |

Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), and others |

Chemical requirements

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pd |

Mo |

Ni |

Ti |

|

Gr1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

bal |

Tensile requirements

|

Grade |

Tensile strength(min) |

Yield strength(min) |

Elongation(%) |

||

|

ksi |

M Pa |

ksi |

M Pa |

||

|

1 |

35 |

240 |

20 |

138 |

24 |

|

2 |

50 |

345 |

40 |

275 |

20 |

|

5 |

130 |

895 |

120 |

828 |

10 |

|

7 |

50 |

345 |

40 |

275 |

20 |

|

9 |

90 |

620 |

70 |

438 |

15 |

|

12 |

70 |

438 |

50 |

345 |

18 |

In general, these flanges are rated at about two-thirds of the strength of a standard long weld neck flange and they have a fatigue life of about one-third of that of a comparable long-weld neck flange. They are connected to pipes using two filet welds, one at the outside of the flange and another at the inside of the flange. This makes them a bit more time consuming to install on a pipe, as well as reduces the versatility of the flange because combining them with elbow and tees is not possible. All fittings used with slip-on flanges must have a straight end.

![]()

![]()

Application field of Titanium Slip On Pipe Flange

1.Chemical processing: Titanium slip-on pipe flanges are often used in chemical processing plants for pipelines that transport highly corrosive chemicals. The excellent corrosion resistance of titanium makes it an ideal material for such applications.

2.Oil and gas: Titanium slip-on pipe flanges are used in oil and gas pipelines, particularly for offshore applications where corrosion resistance and durability are crucial.

3.Power generation: In power plants, titanium slip-on pipe flanges are used in pipelines that transport steam, condensate, and other fluids. The high strength and corrosion resistance of titanium make it a suitable material for such applications.

4.Aerospace: Titanium slip-on pipe flanges are used in the aerospace industry for rocket engines, aircraft engines, and other components that require a lightweight and high-strength material.

5.Medical: Titanium slip-on pipe flanges are used in medical implants and prosthetics due to the biocompatibility, corrosion resistance, and lightweight nature of titanium.

6.Marine: In marine environments, titanium slip-on pipe flanges are used for pipelines that transport seawater, chemicals, and other fluids. The corrosion resistance of titanium makes it an ideal material for such applications.

These are just some of the industries and applications where titanium slip-on pipe flanges can be used. Their high strength, corrosion resistance, and biocompatibility make them suitable for a wide range of applications in various industries.

Application case of Titanium Slip On Pipe Flange In the chemical processing industry

In the chemical processing industry, highly corrosive chemicals are often transported through pipelines. To prevent leaks and ensure safe operation, high-quality flanges are required. In one such application, a chemical company needed to replace the flanges on a pipeline that was transporting hydrochloric acid.

They chose to use titanium slip-on pipe flanges due to the excellent corrosion resistance of titanium. The flanges were made of Grade 2 titanium and were designed to meet ANSI B16.5 specifications. They were also customized with a raised face and a smooth surface finish to ensure a leak-free connection.

The titanium slip-on pipe flanges were installed on the pipeline, and the hydrochloric acid was successfully transported without any leaks or issues. The chemical company was pleased with the performance of the flanges and decided to use them on other pipelines throughout their facility.

This application case highlights the importance of using high-quality flanges in corrosive environments, and the advantages of using titanium slip-on pipe flanges in such applications.

Tag: Slip-On Pipe Flange, titanium Flange, Titanium Pipe Flange