-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

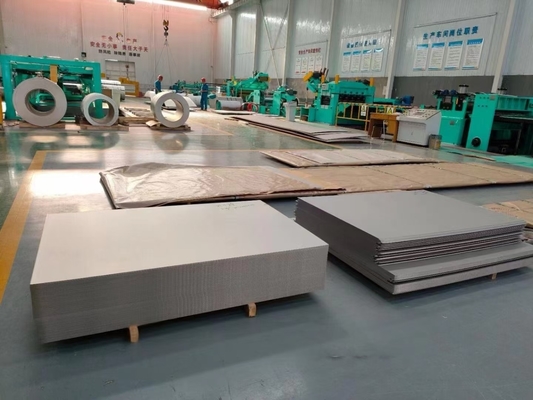

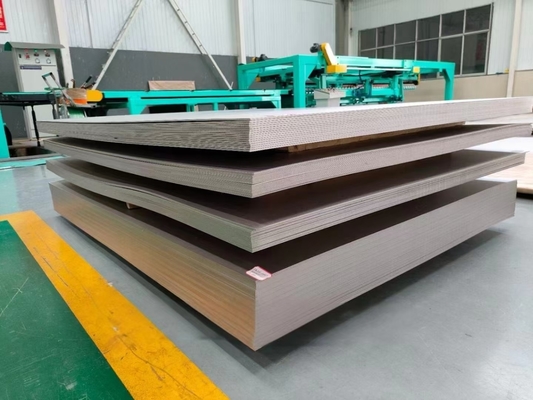

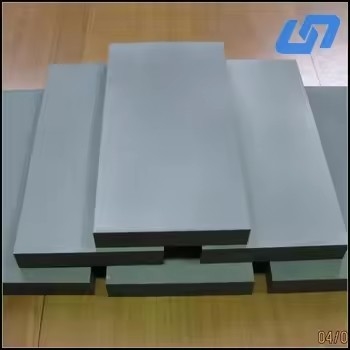

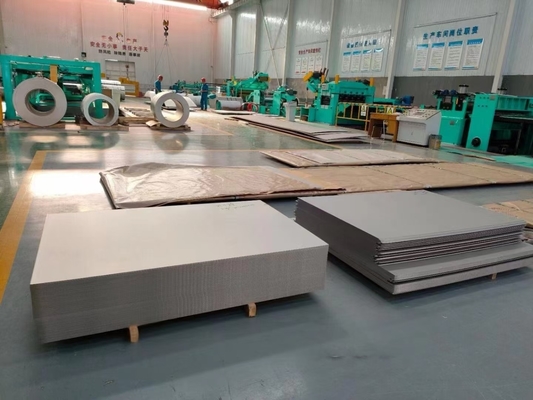

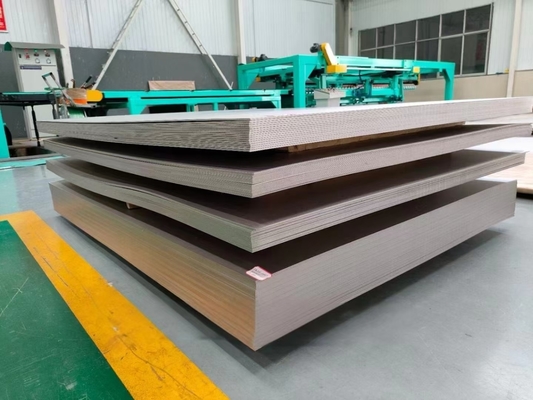

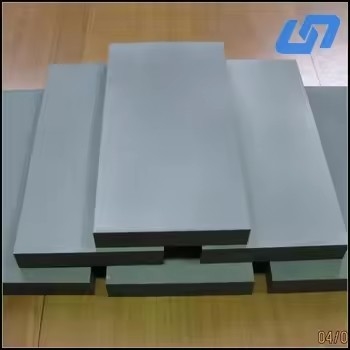

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

ASTM B265 4x8 Gr2 Gr5 8mm Titanium Alloy Sheet Ti 6al 4v Gr5 Aerospace

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Advantage | Durability Stability And Lower Weight | Shape | In Coil, In Flat,or Be Filmed |

|---|---|---|---|

| Others Alloy | Pd,Palladium,6al4v,Ti5Al-2.5Sn | Yield Strength | ≥ 828MPa |

| Wall Thickness | 0.3-20mm | Other Grade | Titanium Gr5/TA10 |

| Stanndard | ASTM B265 | Density | 4.51 G/cm³ |

| Supply Shape | In Coil, In Flat,or Filmed | Plate Surface | Pickling And Smooth Surface |

| Inventory | Various Sizes In Stock | Others Name | Titanium Plate,titanium Sheet |

| Supply State | Bright And Vacuum Annealing | Quality Certificates | ISO 9000:2015 |

| Grade | Gr1, Gr2, Gr5, Gr7, Gr9, Gr12 | ||

| Highlight | Gr5 Titanium Alloy Sheet,8mm Titanium Alloy Sheet,ASTM B265 Titanium Alloy Sheet |

||

Specification

Standard: AMS 4911

Material: Titanium Alloy Ti-6Al-4V (UNS R56400)

Type: Coiled Sheet / Sheet / Plate

Available Forms and Sizes

| Product Type | Size Range (Thickness) |

|---|---|

| Titanium Coil | 0.12" – 0.125" |

| AMS 4911 6Al-4V Titanium Sheet | 0.012" – 0.125" |

| AMS 4911 6Al-4V Titanium Plate | 0.125" – 4" |

Common Sheet Sizes:

0.032" × 36" × 96"

0.040" × 36" × 96"

0.063" × 36" × 96"

0.071" × 36" × 96"

0.080" × 36" × 96"

0.090" × 36" × 96"

Maximum Sheet Size:

Thickness from 0.012", width ≤ 59", length ≤ 118"

Mechanical Properties

| Property | Requirement |

|---|---|

| Tensile Strength (min) | 900 MPa |

| Yield Strength at 0.2% Offset (min) | 825 MPa |

| Elongation (A50mm, min) | 10% |

| Hardness | 36 HRC (approx. 360 HV) |

Chemical Composition (Weight %)

| Element | Min | Max |

|---|---|---|

| Aluminum (Al) | 5.50 | 6.75 |

| Vanadium (V) | 3.50 | 4.50 |

| Iron (Fe) | — | 0.30 |

| Oxygen (O) | — | 0.20 |

| Carbon (C) | — | 0.08 |

| Nitrogen (N) | — | 0.05 (500 ppm) |

| Hydrogen (H) | — | 0.015 (150 ppm) |

| Yttrium (Y) | — | 0.005 (50 ppm) |

| Other Elements, each | — | 0.10 |

| Other Elements, total | — | 0.40 |

| Titanium (Ti) | Balance |

Applications

1. Aerospace Industry

Titanium Grade 5 is the primary alloy used in aircraft structures and engine components due to its high strength-to-weight ratio, heat resistance, and oxidation resistance.

Applications include:

Jet engine compressor blades and discs

Aircraft skins and structural panels

Fasteners and landing gear components

2. Medical and Healthcare

With excellent biocompatibility, Titanium Gr5 is widely used in:

Orthopedic implants and prosthetics

Dental implants

Surgical instruments

3. Marine and Offshore Engineering

Titanium’s seawater corrosion resistance makes it ideal for:

Submarine hulls and propeller shafts

Offshore oil platform components

Seawater piping and heat exchangers

4. Automotive and Motorsport

Used in high-performance vehicles to reduce weight and increase durability:

Engine valves and connecting rods

Exhaust systems

Suspension components

Key Features

High strength-to-weight ratio

Excellent corrosion and oxidation resistance

Superior biocompatibility

Good weldability and formability

Non-magnetic and lightweight

Applicable Standards

AMS 4911 – Sheet, Strip, and Plate

ASTM B265 – Titanium and Titanium Alloy Sheet, Strip, and Plate

UNS R56400 – Ti-6Al-4V

ISO 5832-3 – Surgical Implant Applications