-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

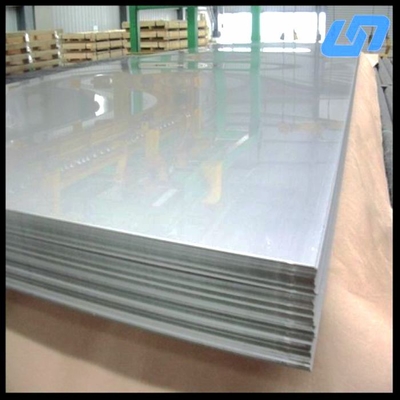

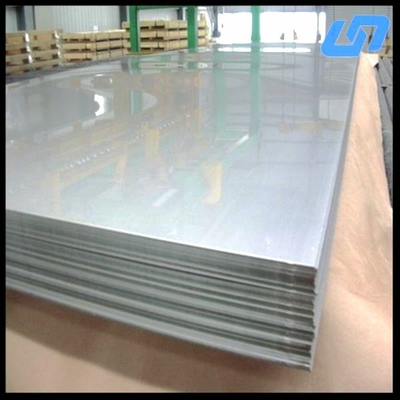

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

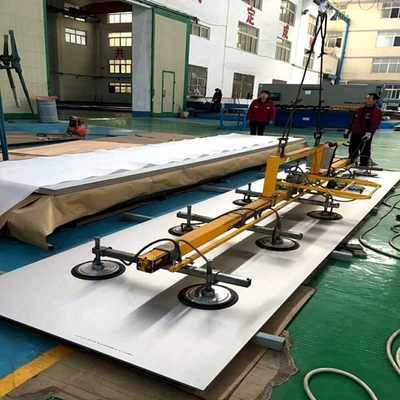

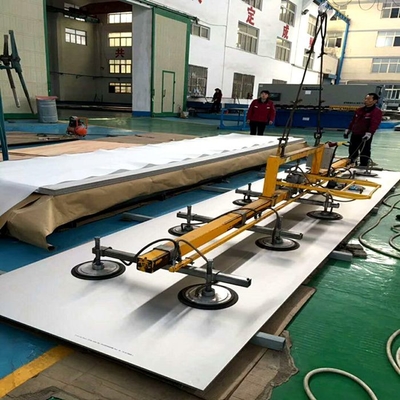

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

BT22/TC18 Titanium Alloy Sheet Thickness 12mm to 60mm For Aircraft Bearing Components

| Features | Lightweight, High Strength, Corrosion Resistant | Shape | Sheet |

|---|---|---|---|

| Technical | Rolling And CNC | Technique | Hot Rolled |

| Sizes | Thickness12mm-60mm,wide1000mm-2000mm,length2000mm-6000mm | Techique | Cold Rolled |

| Applications | Aircraft Bearing Components | Keywords | TC18/BT22 Titanium Alloy Sheets |

| Highlight | 12mm 60mm Titanium Alloy Sheet,BT22/TC18 Titanium Alloy Sheet |

||

BT22/TC18 Titanium Alloy Thickness 12mm to 60mm For Aircraft Bearing Components

Introduction

BT22 also be called TC18 in china or Ti-5Al-4.75Mo-4.75V-1Cr-1Fe

BT22 is a high-strength near β-type titanium alloy with a nominal composition of Ti-5Al-5Mo-5V-1Cr-1Fe. Its chemical composition range is as follows: 4.5%-5.9% Al, 4.0%-5.0% Mo, 4.0%-5.5% V, 0.5%-2.0% Cr, and 0.5%-1.5% Fe. In the annealed state, the alloy possesses a high level of strength, which can reach up to 1080 Mpa. With strengthening treatment, the strength can be further increased to 1300 Mpa, making it the alloy with the highest strength among existing titanium alloys that are annealed. It also has excellent hardenability, with the thickness of cross-section hardenability reaching up to 250 mm.

Since the cross-section thickness is not limited by hardenability, various processes such as ordinary low-cost die forging (on a die forging hammer) and hot die forging, including isothermal die forging, can be used to produce near-net shape forgings. This makes it suitable for manufacturing large-scale aircraft bearing components.

BT22 alloy is characterized by its high strength, high toughness, good plasticity, and excellent welding performance. It can be used to manufacture fasteners for the fuselage, wing force parts, and operating systems that operate at temperatures ranging from 350-400℃ for extended periods. Additionally, it can be used to produce fan discs and blades in engines where the operating temperature does not exceed 350℃. By replacing high-strength steel with BT22 alloy in aircraft structures, there can be a significant weight reduction of 15%-20%.

BT22/TC18 Titanium Alloy Specification

Titanium rod: Dimension 5mm-200mmx L

Titaniumplate:dimension thickness12mm-60mm,wide1000mm-2000mm,length2000mm-6000mm

Titanium forgings: as requests.

Smelting method: Electrode pressing + three vacuum consumption

Chemical Composition wt%

| Al | Mo | V | Cr | Fe | Si | Zr | C | N | H | O |

| 4.4~5.7.1 | 4.0~5.5 | 4.0~5.5 | 0.5~1.5 | 0.5~1.5 | ≤0.15 | ≤0.30 | ≤0.08 | ≤0.05 | ≤0.015 | ≤0.18 |

Mechanical properties (transverse forging)

| Room temperature(20℃) | σb MPa | σ0.2 MPa | A % | Z % | Ak J | HBd | ||||

| 1218 | 1188 | 12 | 42 | - | 3.17 | |||||

| 1193 | 1166 | 13 | 36 | - | 3.14 | |||||

Features And Applications

The BT22 titanium alloy is renowned for its superior strength, high plasticity, excellent hardenability, and weldability. In its annealed state, the microstructure consists of roughly equal amounts of α phases (alpha) and β phases (beta), which contributes to it being the highest-strength titanium alloy among those in the annealed condition.

Similarly, another titanium alloy, TC18, also offers a variety of welding methods that can be employed after annealing, ensuring good welding performance. The maximum operating temperature for TC18 titanium alloy is up to 400℃.

Applications for the BT22 titanium alloy are primarily in the aerospace industry, where it is used for large load-bearing components and parts of aircraft bodies and landing gears. It is also instrumental in the manufacturing of engine fan discs and blades that operate at temperatures not exceeding 350℃. Additionally, it is used in producing vital bearing components such as forks and torque arms on landing gear force members.

Beyond aerospace, the BT22 alloy finds use in other high-performance applications such as rockets, artillery, mortars, and shells, benefiting from its unique combination of mechanical properties and ability to withstand high temperatures.