-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

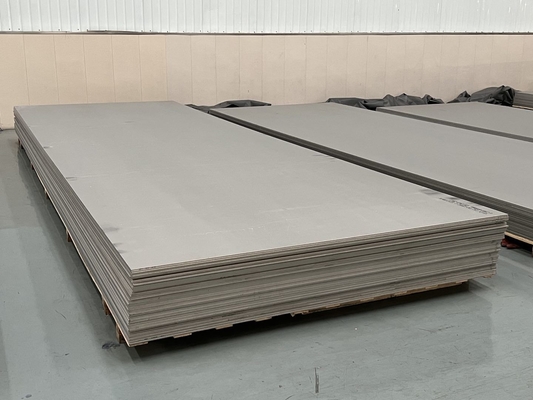

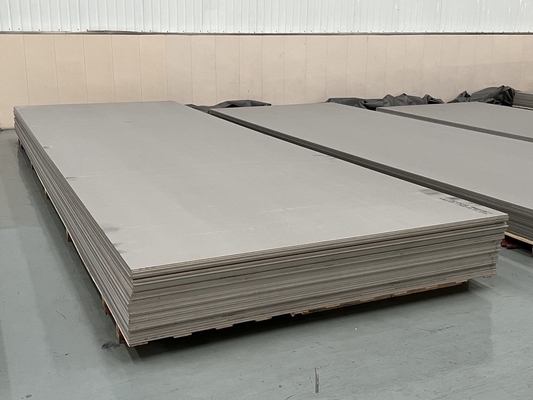

factory ASTM B265 Gr2 Pure titanium sheet titanium alloy Plate for industrial

| Place of Origin | China Baoji |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001 |

| Model Number | CSTY-PL |

| Minimum Order Quantity | 10kg |

| Price | 10-300USD/Pc |

| Packaging Details | Caroton Boxes or Export Wood Case Or As Client Requried |

| Delivery Time | 15-25Days |

| Payment Terms | T/T, L/C or Negotiation |

| Supply Ability | 100Tons per month |

| Shape | Rectangle | Surface | Acid Wash ,Polished |

|---|---|---|---|

| Grade | Titanium Gr1 Gr2 Gr5 Gr7 Gr9 | Size | Regular 1000*2000mm Or As Your Required |

| Thickness | 0.01-20mm | Standard | ASTM B265/ASTM F136/76 /AMS4928 |

| Highlight | Pure Titanium Sheet Plate,Titanium Sheet Plate Gr7,Rectangle Pure Titanium Plate |

||

Factory Pure Titanium Sheet Titanium alloy Plate In Gr1 Gr2 Gr5 Gr7 Gr9 With ASTM B265

There are two kinds of titanium plate implementation standards, GB/T3621-2007, GB/T13810-2007, the American standard is ASTM B265, ASTM F136, ASTM F67, AMS4928.

American label number: GR1, GR2, GR3, GR5, GR7, GR12

Russian label number: BT1-00, BT1-0, BT1-2, etc

Domestic brand: TA0, TA2, TA3, TA5, TA6, TA7, TA9, TA10, TB2, TC1, TC2, TC3, TC4

1. Reference Standard

1: GB 228 Metal tensile test method

2: GB/T 3620.1 Titanium and titanium alloy grades and chemical composition

3: GB/T3620.2 Titanium and titanium alloy processed products chemical composition and composition allowable deviation

4: GB 4698 Sponge titanium, titanium and ferroalloy chemical analysis methods

Titanium plate specification

Brand :TA1, TA2, TA3, TC4, GR1, GR2, GR5

Standard :GB/T 3621-2007,GB/T 13810-2007ASTM B265,ASTM F136,ASTM F67,

Size :T(0.3 ~3.0) × W(400 ~1000) × L≤ 3000mm T(0.1~0.3) × W(100 ~500) ×L as your length mm T(0.02~0.1) × W(50~300) ×L as your length mm T 0.5-5.0mm x W1000mm x L 2000-3500mm T 6.0-30mm x W1000-2500mm x L 3000-6000mmt 30-80mm x W1000mm x L 2000mm

Use :Metallurgy, electronics, medical, chemical, petroleum, medicine, aerospace, etc.

Titanium plate manufacturing process

Hot forging Forging process performed above the recrystallization temperature of a metal.

Hot rolling a rolling process at a temperature higher than recrystallization.

Cold rolling process in which the plastic deformation temperature is lower than the recovery temperature.

Annealing: A process of heat treatment of metals by heating them slowly to a certain temperature, holding them for a sufficient time, and then cooling them at a suitable rate (usually slow cooling, sometimes controlled cooling).

Pickling: Immersion of a product in an aqueous solution, such as sulfuric acid, to remove a thin film, such as oxide, from the metal surface. It is the pretreatment or intermediate treatment of electroplating, enamel, rolling and other processes

Characteristics of titanium plate

1 titanium plate is the surface of the oxide film is equivalent to a good wear-resisting hair separation agent, the use of titanium plate to save the separation agent, so that the plate is easy to peel, avoid the process of pre-processing of the plate, titanium plate is half lighter than the copper plate.

2. The service life of titanium seed plate is more than 3 times that of copper seed plate, up to 10 to 20 years according to the operating conditions

3. The electrolytic copper prepared with titanium seed plate has compact crystal structure, smooth surface and excellent quality.

4. Because titanium plate does not need to smear separation agent, it can avoid the pollution of copper electrolyte.

5. Improve the capacity and reduce the production cost of electrolytic copper, so as to have better economic benefits.

tag:titanium sheet metal,titanium metal sheet,titanium sheet metal for sale