-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

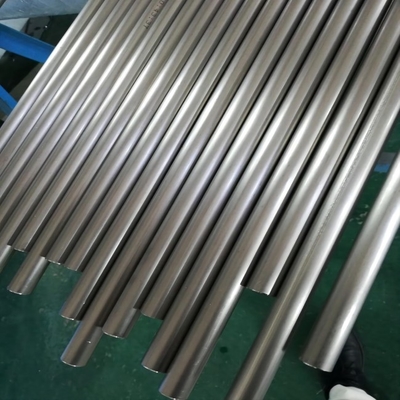

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

grade 12 welding titanium pipe for heat exchanger 3000mm

| Place of Origin | China Baoji |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001:2015 |

| Model Number | CSTY-TB |

| Minimum Order Quantity | 100kg |

| Price | 28-50USD/Kg |

| Packaging Details | Caroton Boxes or Export Wood Case Or As Client Requried |

| Delivery Time | 15-30days |

| Payment Terms | T/T, L/C or Negotiation |

| Supply Ability | 100Tons per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Titanium Gr12 | Standard | ASTM B862 |

|---|---|---|---|

| Outer Diameter | 0.8-4.0mm | Length | Max: 16000mm |

| Wall Thickness | 0.5-10mm | Type | Welded |

| Advantage | Titanium Pipe Welding Factory | ||

| Highlight | 4mm titanium tube,16000mm titanium tube,TA10 ti tube |

||

Thin-Walled Titanium Tubes Titanium Pipe For Heat Exchanger

Thin-walled titanium tubes: Wall thickness ranging from 0.7-1 mm

Medical capillary titanium tubes: Diameters of ≥ 0.2 mm

Capillary tube: OD: 0.8—4.0 mm, WT: 0.05---1.0 mm, L: 10.0—13000.0 mm

Special Shaped Titanium Tubes

We can provide square, hexagonal, elliptic and other special-shaped titanium tubes according to customers’ specifications.

We also provide DN80-DN1200 welded pipes of nickel and other alloys, Hastelloy alloys as well as other special metals.

Surface treatments of Titanium Tube / Pipe: 1) Anodizing 2) Polishing 3) Powder coated 4) Electrophoresis 5) Sand-blast 6) Coating film

| Material | Process | Processing State | Diameter [mm] | Standards |

| TA0,TA1, TA2, TA9 TA10 Gr1, Gr2, Gr7, Gr11, Gr12, Gr17, nickel, niobium, molybdenum | Cold rolled | Cold rolled, annealed | Φ3-273 |

GB/T3624-2005 GB/T3625-2005 ASTM B337 ASTM B338 ASTM B861 |

| TA0,TA1, TA2, TA9 TA10 Gr1, Gr2, Gr7, Gr11, Gr12, Gr17, nickel, niobium, molybdenum | Welded | annealed | Φ10-40 |

GB/T3624-95 GB/T3625-95

|

FAQ

1. Are you the manufacturing or trading company?

Real manufacturing company, started from 2001, nearly 20 years. With 2 sales teams for foreign trading business, started from 2008, more than 10 years experiences.

2. Do you have a dedicated R & D team? Can you design a product for us?

We have a dedicated technical team responsible for research and development. But most of titanium fittings are standard, we can follow ASTM or other you asked.

3. Can you provide samples? Is there a charge?

Samples can be provided for a fee.

4. What is your payment method?

We can accept T / T, LC, trade assurance order from alibaba.com. Samples are 100% prepaid. Orders for mass production are below 1000 USD, 100% prepaid, above 1000 USD, 30% prepaid, and 70% paid before delivery.

5. How long is your delivery time?

Inventory samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances.

6. After-sales products, how to deal with problems?

Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem:

1) Among the products that have problems, 93% are misplaced in pre-sales communication, and the product that the customer needs is not really clear.

2) 5% is an unexpected situation and the extension of the construction period.

3) 2% is the problem of transportation and packaging. During long-distance transportation, the packaging is damaged and the surface is damaged.

7. What is your company's response to the product in question?

1) Verify and blame for pre-sales communication issues. Compensation is handled according to the proportion of liability.

2) We are 100% responsible for problems caused by damaged packaging during transportation.

Tag:titanium pipe welding ,pipe ,tube ,titanium welded pipe,titanium pipe welding factory