All Products

-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

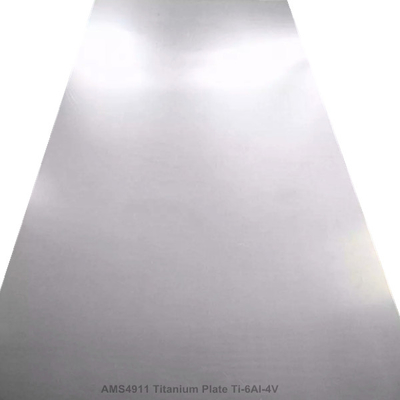

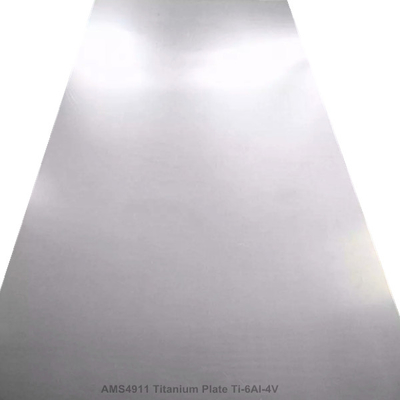

manufacturer ASTM F67 titanium sheet Gr1 Polished Surface for medical application

| Place of Origin | China Baoji |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001 |

| Model Number | CSTY-PL |

| Minimum Order Quantity | 10kg |

| Price | 28-50USD/Kg |

| Packaging Details | Caroton Boxes or Export Wood Case Or As Client Requried |

| Delivery Time | 15-25Days |

| Payment Terms | T/T, L/C or Negotiation |

| Supply Ability | 100Tons per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Width | 300-1000mm | Technique | Hot Rolled |

|---|---|---|---|

| Grade | Gr1 Gr2 Gr5 Eli | Surface | Acid Picking /Sand Blast /Polished |

| Length | <6000mm | Standard | ASTM F67/ASTM F136 |

| Thickness | 0.5-40mm | Processing Service | Bending ,Cutting |

| Highlight | ASTM F67 Titanium Alloy Sheet,Gr1 Titanium Alloy Sheet,Polished 6al4v titanium sheet |

||

Product Description

Polished Surface ASTM F67 Gr1 Gr2 Titanium sheet Plate For Medical Implant

1. Titanium sheet Advantage:

1.Titanium sheet is the surface of the oxide film is equivalent to a good long-term wear-resistant release agent, the use of titanium plate to save the separation agent, so that easy to peel off the plate,eliminating the pre-treatment process, The board is lighter than the copper plate.

2. Titanium plate of the life of copper plate is more than 3 times, according to operating conditions up to 10 to 20 years

3. With titanium plate made of electrolytic copper crystal structure dense, smooth surface, excellent quality.

4. Since the titanium plate does not need to apply the separating agent, it can avoid the pollution of the copper electrolyte.

5. To improve production capacity to reduce the cost of electrolytic copper production, which has a better economic benefits.

2. Titanium plate of the life of copper plate is more than 3 times, according to operating conditions up to 10 to 20 years

3. With titanium plate made of electrolytic copper crystal structure dense, smooth surface, excellent quality.

4. Since the titanium plate does not need to apply the separating agent, it can avoid the pollution of the copper electrolyte.

5. To improve production capacity to reduce the cost of electrolytic copper production, which has a better economic benefits.

2. Production Specification:

Cold -rolling plate :(Y state)×Thickness(0.3-0.4mm)×Width(400-2000mm)×L mm

Hold-rolling plate:(R State )×Thickness(4.0-30mm)×Width(400-3000mm)×L9000mm

Foil/Strip :Thickness(0.1-6.0mm )×Width(100-1500mm)×L mm

3. Method to Produce :

Forging /Cold-Rolling/ Hot-Rolling

4. Standard:ASTM B265. ASTM F136 .ASTM F67 .AMS4911 .ASTM B381 Etc

5. Production Process:

Sponge titanium - melting - heating - forging - slab - grinding - hot rolling - annealing - grinding - cold rolling - annealing -pickling - leveling - shearing - packaging

6. Application :

The products are widely used in chemical equipment, vacuum salt making, automobile industry, paper and textile industry, electric power industry, chlor-alkali industry, chemical fertilizer industry, sea water desalination and so on

7. Availability Status:Annealed Condition

8. Tolerance for Thickness

|

Tickness Allowble Deviation

|

|

|

Thickness(mm)

|

Tolerance(mm)

|

|

(3.71 to 4.76), excl

|

0.36

|

|

3.33 to 3.68

|

0.31

|

|

2.92 to 3.30

|

0.25

|

|

2.51 to 2.90

|

0.23

|

|

2.13 to 2.49

|

0.20

|

|

1.85 to 2.11

|

0.18

|

|

1.50 to 1.83

|

0.15

|

|

1.04 to 1.47

|

0.13

|

|

0.69 to 1.02

|

0.10

|

|

0.43 to 0.66

|

0.08

|

|

0.20 to 0.41

|

0.05

|

|

0.15 to 0.18

|

0.04

|

|

0.13

|

0.03

|

Tag:titanium alloy plate ,titanium alloy sheet,titanium plate for medical implant,factory supplier

Recommended Products