-

Titanium Pipe Fittings

-

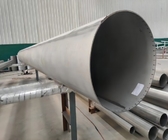

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Factory supplier ASTM B338 titanium welded pipe OD377mm For Ocean Engineering

| Material | Gr1 | OD | 377mm Or As Your Requried |

|---|---|---|---|

| Length | 6000mm | Surface | Acid Picking |

| Wall Thickness | 6mm Or As Your Requried | Others Grade | Gr1 GR2 GR5 GR7 |

| MOQ | 100KGS | Technology | Welding |

| Weight | Actual Weight | Standard | ASTM B338 |

| Application | Ocean Engineering | ||

| Highlight | Ocean Engineering Titanium Welded Pipe,6000mm Titanium Welded Pipe,377mm Titanium Welded Tube |

||

Factory supplier ASTM B338 titanium welded pipe OD377mm For Ocean Engineering

Advantage Compare others material :

1.Excellent high and low temperature performance. At present, the working temperature of new heat - resistant titanium alloy

can reach 550-600℃ .Low temperature titanium alloy can maintain good toughness at -253.

2.Strong corrosion resistance The surface will quickly form thin and dense titanium oxide film, so in the atmosphere, seawater,

nitric acid and sulfuric acidand other oxidizing medium and strong alkali, its corrosion resistance is better than most

stainless steel.

Compapare Titanium Seamless tube :

1. Pipe fittings with thinner thick walls can be manufactured. For example, the wall thickness of welded pipe can be 0.3~0.5mm,

while the minimum wall thickness of seamless pipe is 1mm.

2. High utilization rate of raw materials;

3. High production efficiency and good economic benefits.

titanium pipe welding Size and Details:

| Size | 377*6*6000mm Or As your requried |

| Grade | Gr1 Or others titanium grade |

| Application 1 | Seawater desalination, thin wall welded titanium tube for heat transfer |

| Application 2 | Deep sea oil field drilling titanium condensate tube heat exchange tube |

| Application 3 | Seawater system: titanium ballast water pipe, control valve and catchment valve, etc |

| Application 4 | Ocean thermal power station,titanium evaporator and condenser heat transfer tube, heat exchanger |

| Application 5 | Steam turbine titanium blades:Not subject to water erosion by steam agglutinationReduce the cost of power generation Increased equipment durability |

| Grade No. | Fe max wt% | O max wt% | N max wt% | C max wt% | H max wt% | Pd max wt% | Al max wt% | Bal max wt% |

| GR1 | 0.2 | 0.18 | 0.03 | 0.1 | 0.015 | - | - | Ti |

titanium mechanical property

| ASTM Grade | Alloy composition | Tensile Strength ksi | Tensile Strength Mpa | Yield Strength Ksi | Yield Strength Mpa | Elongation % |

| GR1 | Unalloyed Ti(Pure Ti) | 35 | 240 | 25 | 170 | 24 |

FAQ

1. Are you the manufacturing or trading company?

Real manufacturing company, started from 2001, nearly 20 years. With 2 sales teams for foreign trading business, started from 2008, more than 10 years experiences.

2. Do you have a dedicated R & D team? Can you design a product for us?

We have a dedicated technical team responsible for research and development. But most of titanium fittings are standard, we can follow ASTM or other you asked.

3. Can you provide samples? Is there a charge?

Samples can be provided for a fee.

4. What is your payment method?

We can accept T / T, LC, trade assurance order from alibaba.com. Samples are 100% prepaid. Orders for mass production are below 1000 USD, 100% prepaid, above 1000 USD, 30% prepaid, and 70% paid before delivery.

5. How long is your delivery time?

Inventory samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances.

6. After-sales products, how to deal with problems?

Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem:

1) Among the products that have problems, 93% are misplaced in pre-sales communication, and the product that the customer needs is not really clear.

2) 5% is an unexpected situation and the extension of the construction period.

3) 2% is the problem of transportation and packaging. During long-distance transportation, the packaging is damaged and the surface is damaged.

7. What is your company's response to the product in question?

1) Verify and blame for pre-sales communication issues. Compensation is handled according to the proportion of liability.

2) We are 100% responsible for problems caused by damaged packaging during transportation.

Tag:welding titanium pipe ,titanium welded tube .titanium pipe welding