-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

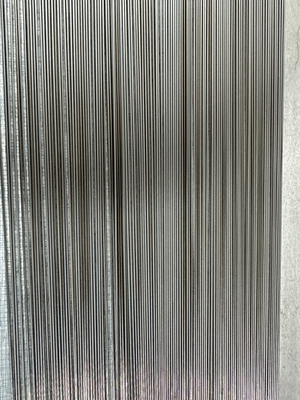

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

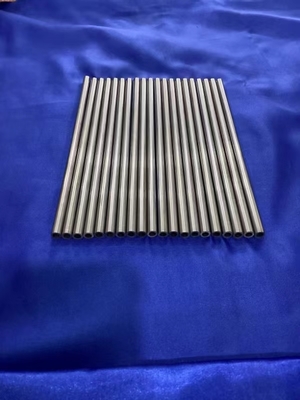

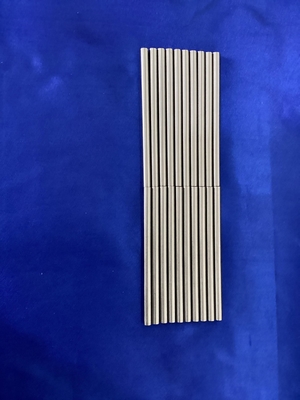

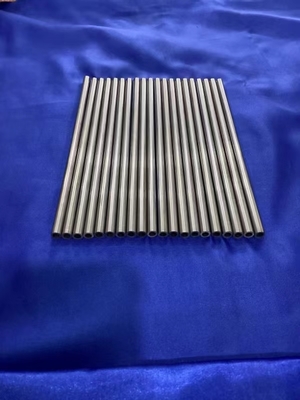

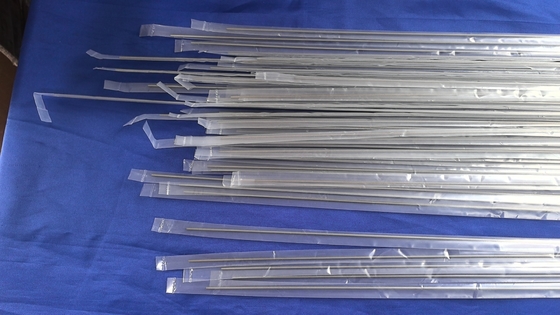

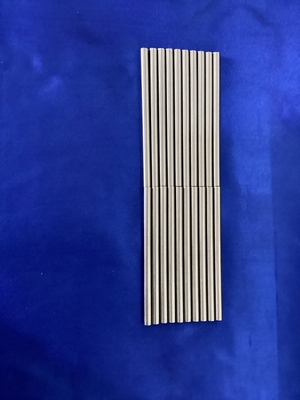

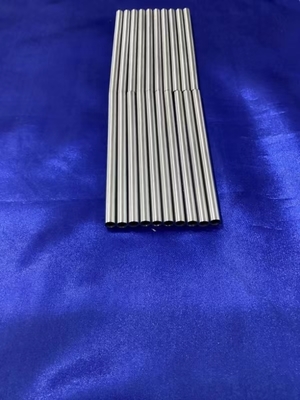

RO4200-1 RO4210-2 Niobium Capillary Tube Throttling And Pressure Increase

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Commodity | Niobium Tube | Chemical Composition | Nb>=99.95% |

|---|---|---|---|

| Method | Electron Beam Furnace Smelted | Dimensions | ¢3~¢120mm |

| Size | Customized | Purity | 99.9%(3N) |

| Standard | ASTM B393 | Conditions | Vacuum Annealed |

| Material Standard | ASTM B 365-98 | Technique | Sintering,Forging,Machining |

| Technology | CNC Milling Machinery | Heat Of Fusion | 26.4KJ/mol |

| Vapourization Temperature | 2350℃ (under 10-4Torr) | Yield Strength | 73Mpa |

| Discovery Year | 1801 | Original Place | CHINA |

| Specific Heat Capacity | 0.265 J/g·K | Grade | RO4200 |

| Atomic Number | 41 | Surface Condition | Cleaned Or Black |

| Processing | Cold Rolling | Manufacturing Standard | ASTM B392-95 |

| Melting Point | 2,468°C | Specification | Customized |

| Shape | Tube | Electrical Conductivity | 0.0693 10^6/cm |

| Density | 8.57 G/cm³ | Keyword | Niobium Capillary Tubes |

| Highlight | niobium capillary tube throttling,niobium pressure increase tube,niobium products with warranty |

||

Introduction

Niobium tube is a specialized metallic pipe used for conveying and transferring materials under high-temperature and high-pressure conditions.

Thanks to niobium’s exceptional corrosion resistance, high-temperature stability, and mechanical strength, these tubes exhibit superior compressive, tensile, fatigue, and thermal resistance properties.

As a result, niobium tubes are widely applied in nuclear technology, aerospace, shipbuilding, chemical processing, and electronic industries, where reliability and performance in extreme environments are critical.

Chemical Composition

| Grade | Main Component | Other Impurities (≤%) |

|---|---|---|

| Nb | Fe | |

| Nb1 | Remainder | 0.004 |

| Nb2 | Remainder | 0.01 |

Surface Treatment

Common surface treatment methods for niobium tubes include:

Mechanical Polishing – Improves surface smoothness and dimensional precision.

Electrolytic Polishing – Enhances corrosion resistance and achieves a bright, mirror-like finish.

Pickling – Removes oxides, oil, and other surface contaminants to restore metallic luster.

Sandblasting – Cleans and textures the surface, improving coating adhesion and uniformity.

These treatments enhance both the appearance and corrosion resistance of niobium tubes, ensuring excellent performance in demanding environments.

Applications

Niobium tubes have diverse uses across high-technology and industrial sectors, including:

-

High-temperature alloys

-

Niobium-based alloys

-

Steel refining and strengthening

-

Electrical porcelain components

-

Coinage materials

-

Medical devices and implants

-

Aerospace components

-

Electronics and vacuum equipment