-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

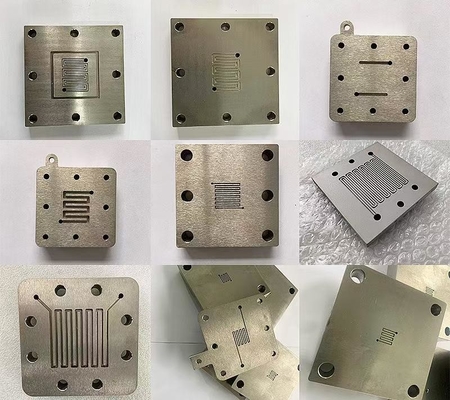

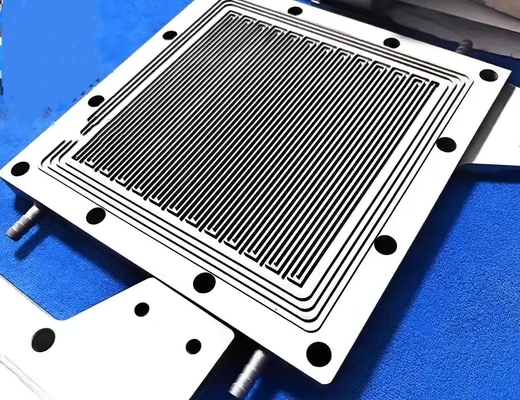

Titanium Bipolar Plates for PEM Electrolyzer

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | Anneal,cold Rolled | Techinique | CNC, ETCHING |

|---|---|---|---|

| Advantage | Durability Stability And Lower Weight | Tolerance | ±0.05mm |

| Surface Finish | Smooth, Matte | Thickness | 0.5-10mm |

| Highlight | Customization Titanium Bipolar Plates,GR1/GR2 Titanium Bipolar Plates,PEM Electrolyzer Titanium Bipolar Plates |

||

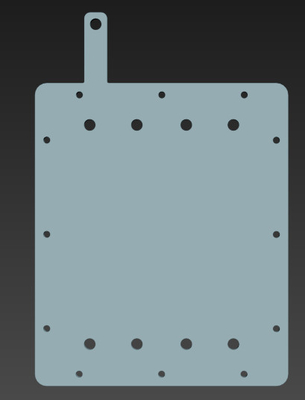

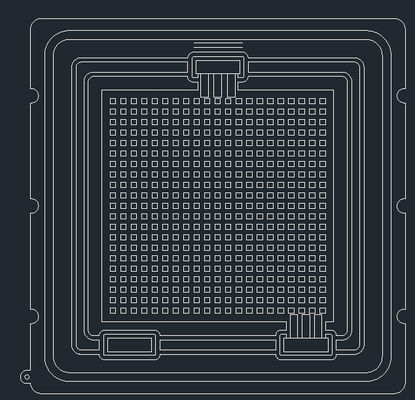

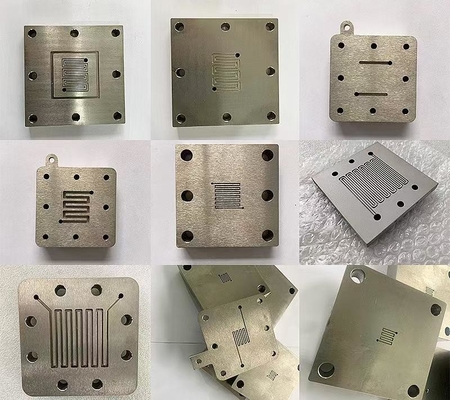

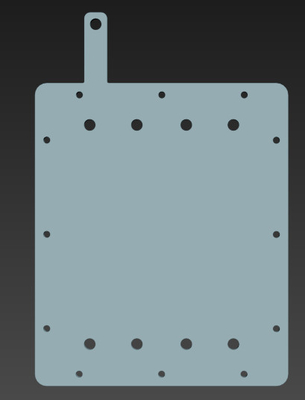

Product Name: Bipolar Plate

Application: Hydrogen production via water electrolysis, new energy batteries, hydrogen-generating fuel cells

Material: Titanium, Stainless Steel, Copper, Nickel

Titanium Purity: 99.7%

Grade: GR1 / GR2

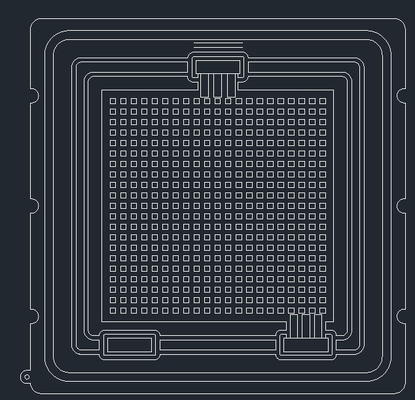

Specification: Custom according to drawings

Processing Method: CNC / Etching

1. Production Process of Titanium Bipolar Plates

Titanium bipolar plates are essential components in PEM fuel cells and PEM water electrolyzers. They are responsible for distributing gases/liquids, conducting electricity, and supporting the membrane-electrode assembly. The production process involves several key steps:

1.1. Raw Material Selection

-

Material: Commercially pure titanium (e.g., Grade 1 or Grade 2) or titanium alloys.

-

Thickness: Typically ranges from 0.1 mm to 1 mm depending on application.

1.2. Surface Pretreatment

-

Pickling: Removes surface oxide layers and contaminants.

-

Sandblasting or Mechanical Polishing: Enhances surface roughness for better coating adhesion.

1.3. Flow Field Forming

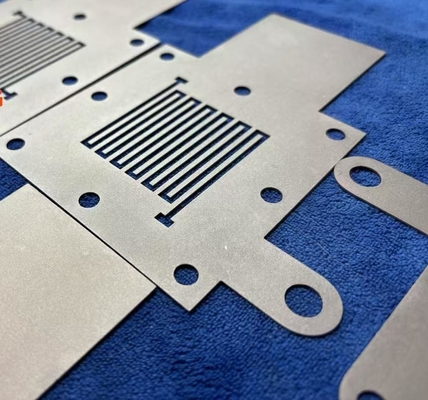

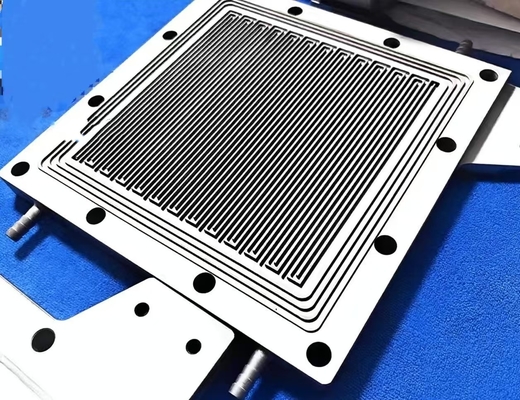

Flow channels are designed to manage the flow of gases or liquids. Common forming methods include:

(a) Stamping

-

High-speed forming using precision dies.

-

Suitable for mass production.

-

Requires durable and high-cost molds.

(b) Roll Forming

-

Continuous production technique.

-

Used for simpler or straight channel patterns.

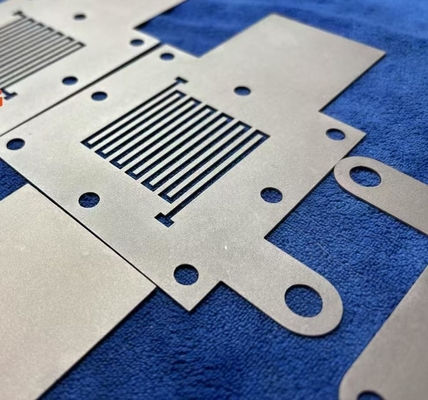

(c) Chemical Etching

-

Precise patterning via photolithography and acid etching.

-

Best for complex or fine structures.

-

Higher cost and involves chemical waste management.

(d) Laser or EDM Machining

-

High-precision techniques suitable for R&D or small batches.

-

Enables very fine and custom flow field structures.

1.4. Welding (For Assembly)

Two patterned titanium sheets may be joined to create a sealed bipolar plate:

-

Laser Welding or Diffusion Bonding: Ensures high sealing performance and structural integrity.

1.5. Surface Coating Treatment

Titanium tends to form a non-conductive oxide layer (TiO₂), which affects electrical performance. Surface coatings are applied to improve conductivity and corrosion resistance.

Typical Coating Types:

-

Carbon-based Coatings: Graphene, carbon nanotubes.

-

Noble Metals: Platinum or gold (excellent conductivity and corrosion resistance, but costly).

-

Conductive Ceramics: Titanium nitride (TiN), niobium nitride (NbN).

1.6. Quality Testing

-

Gas Tightness Test: To ensure sealing.

-

Electrical Conductivity Test

-

Corrosion Resistance Testing

-

Dimensional Accuracy Inspection

2. Applications of Titanium Bipolar Plates

Titanium bipolar plates are used in various electrochemical systems, including:

2.1. Proton Exchange Membrane Water Electrolyzers (PEMWE)

-

Harsh acidic environment and high voltage conditions.

-

Titanium offers excellent corrosion resistance and durability.

2.2. PEM Fuel Cells (PEMFC)

-

Lightweight and corrosion-resistant properties are ideal for portable, automotive, and aerospace applications.

2.3. Electrolytic Cells

-

Used in chemical processing, water treatment, and green hydrogen production.

3. Advantages of Titanium Bipolar Plates

| Advantage | Description |

|---|---|

| Excellent Corrosion Resistance | Ideal for acidic and high-voltage environments. |

| Lightweight | Titanium has a low density (4.5 g/cm³), reducing overall system weight. |

| High Strength | Offers good mechanical strength and pressure resistance. |

| Thermal Conductivity | Facilitates efficient heat management within fuel cell stacks. |

| Long Service Life | Significantly longer lifespan compared to stainless steel or coated materials. |

| Flexible Manufacturing | Compatible with various forming and coating techniques, including high-precision methods. |

4. Challenges

While titanium bipolar plates have many advantages, some challenges include:

-

High Material Cost: Titanium and its coatings are expensive.

-

Processing Difficulty: Titanium is harder to form and machine than steel.

-

Surface Conductivity Needs Optimization: Natural oxide layer requires effective surface treatment to maintain conductivity.