-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

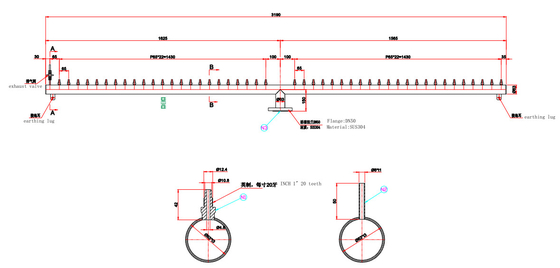

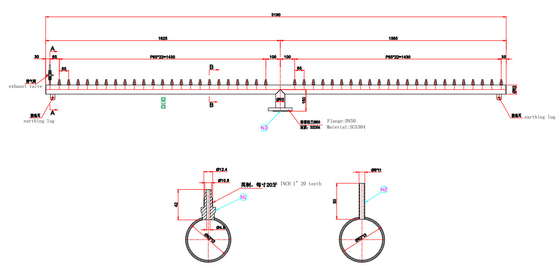

Electrolyzer accessories Anode and cathode cell Inlet distribution pipe for Chlor-alkali plant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Inlet Distribution Pipe Specification | Pipe:OD63*3*3190mm,flange,DN50, According To Drawings | Cell Effective Area | 2.72 M² |

|---|---|---|---|

| Operating Current | 12.16~16.2KA | DC Power Consumption | ≤2065kWH/t100%NaOH ( The Current Density5.1kA/m² ) |

| Unit Cell Voltage | ≤2.96V ( The Current Density5.1kA/m² ) | Inlet Distribution Pipe Material | Anode Titanium And Cathode Nickel |

| Advantages | Excellent Corrosion Resistance In High Temperature And High Concentration Acidic Electrolyte Environment | Service Life | ≥16year |

| Highlight | Cathode Electrolyzer accessories,Anode Electrolyzer accessories |

||

Electrolyzer Accessories — Anode & Cathode Cell Inlet Distribution Pipe for Chlor-Alkali Plant

Product Overview

The Anode and Cathode Cell Inlet Distribution Pipe is a critical component in the chlor-alkali electrolyzer system. Its primary function is to distribute the electrolyte or other process solutions evenly into the electrolytic cell, ensuring stable, efficient, and uniform electrochemical reactions.

1. Material Selection

The inlet distribution pipe must exhibit excellent corrosion resistance and chemical compatibility with the electrolyte solution. Commonly used materials include:

PVC (Polyvinyl Chloride):

Suitable for low-temperature and mildly corrosive environments.

PP (Polypropylene):

Offers enhanced corrosion resistance and is applicable for moderate- to high-temperature electrolysis processes.

PTFE (Polytetrafluoroethylene):

Exhibits outstanding resistance to strong acids and alkalis; ideal for highly demanding electrolysis environments.

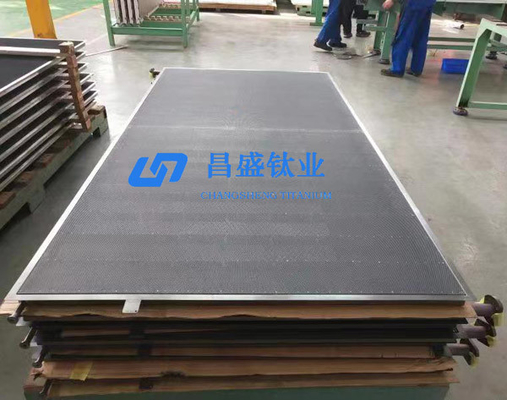

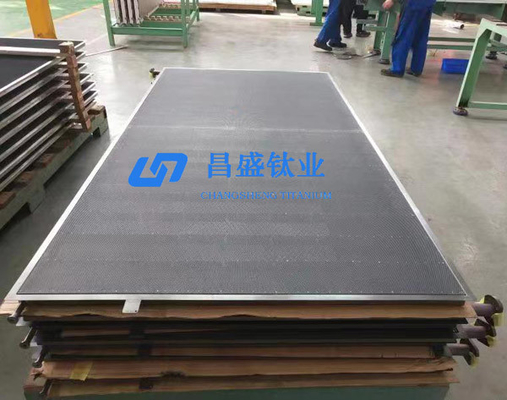

Titanium, Titanium Alloy, and Nickel Materials:

Provide superior corrosion resistance under high-temperature and high-concentration acidic conditions.

(In the design shown below, titanium and nickel materials are adopted for enhanced durability and performance.)

2. Structural Design Features

a. Flow Uniformity

The pipe design ensures uniform electrolyte distribution within the electrolyzer, preventing local concentration gradients that could cause uneven reactions or reduced efficiency.

b. Pressure Control

The inlet pressure is carefully regulated to maintain optimal flow rates, avoiding turbulence or uneven deposition inside the cell.

c. Anti-blocking Design

Equipped with optimized apertures and filtration structures, the pipe prevents impurities from clogging the flow path and ensures stable electrolyte delivery.

d. Temperature Resistance

Designed to operate reliably under varying electrolyte temperatures without deformation, aging, or material degradation.

3. Installation and Maintenance

a. The inlet pipe is typically connected to a circulation pump or electrolyte storage tank to provide continuous electrolyte flow.

b. The system is designed for easy disassembly and cleaning, ensuring convenient maintenance and minimizing downtime.

c. Pressure sensors and flow meters can be installed to monitor real-time inlet conditions, ensuring consistent electrolytic performance.

d. Advanced systems may include automatic control devices to dynamically regulate electrolyte inflow based on cell liquid level and concentration parameters.

Electrolytic Cell Anode Half Shell

Function and Importance

The anode half shell forms a structural and functional part of the anode assembly within the electrolytic cell. It serves multiple critical roles:

-

Uniform Current Distribution

Ensures even current flow throughout the cell, promoting consistent electrochemical reactions and improving product quality. -

Protection and Extended Anode Life

Manufactured from corrosion-resistant materials, the anode half shell protects the anode body from chemical attack by the electrolyte, thereby extending its operational lifespan. -

Structural Stability

Enhances the mechanical strength of the anode, maintaining structural integrity and preventing deformation or mechanical failure during electrolysis.

Applications

Anode half shells are commonly used in electrolytic extraction and refining processes — including copper, aluminum, and other non-ferrous metals — to ensure stable electrochemical performance, improved product quality, and enhanced production efficiency.