-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

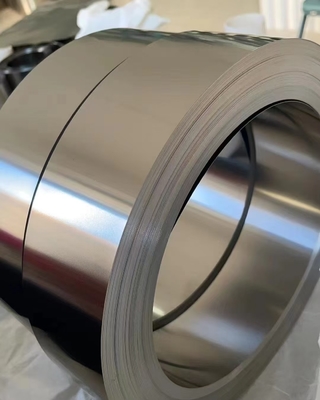

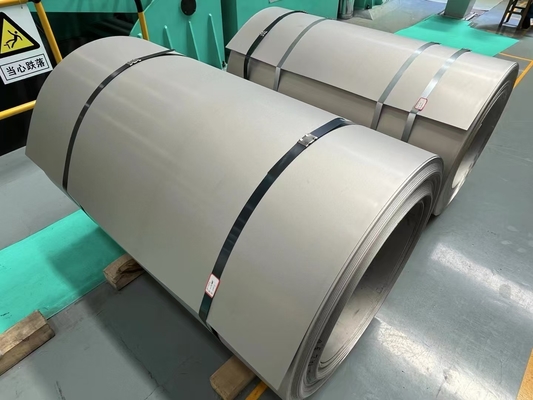

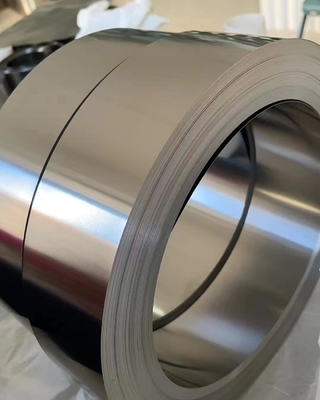

Stainless Steel Products

SS 316L Stainess Steel Foil 0.08mm 0.05mm For Diaphragm Sensor

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | AISI 316L |

| Minimum Order Quantity | 10kgs |

| Price | $18.00 - $64.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Finish | BA/2B/NO. 1/NO.3/NO.4/8K/HL/2D/1D | Business Type | Manufaturer |

|---|---|---|---|

| Technique | Cold Rolled / Hot Rolled | Invoicing | By Theoretical Weight |

| Inspection | Thirdy Inspection Party | Outer Diameter | 17 - 1020 Mm |

| Alloy Or Not | Non-Alloy | Keyword | Stainless Steel Foil |

| Package | Standard Seaworthy Package | Color | Natural Color |

| Shape | Flat.sheet | Strength | High |

| Advantage | High Strength | Special Pipe | API Pipe |

| Heat Resistance | High | ||

| Highlight | 0.05mm SS 316L Stainess Steel Foil,0.08mm SS 316L Stainess Steel Foil |

||

Description

316L is a low-carbon stainless steel grade with superior corrosion resistance and weldability.

It corresponds to the following international standards:

AISI 316L (USA)

SUS 316L (Japan)

S31603 (China)

022Cr17Ni12Mo2 (GB/T 20878-2007, new standard)

00Cr17Ni14Mo2 (old grade)

316L stainless steel contains chromium (Cr), nickel (Ni), and molybdenum (Mo). The addition of molybdenum enhances its resistance to chloride corrosion and high-temperature oxidation, making it one of the most reliable materials for harsh environments.

Specification

| Product Name | SS 316L Foil |

|---|---|

| Material Grades | 301, 310S, 316Ti, 316L, 316, 321, 314, 304, 304L |

| Thickness | 0.05mm, 0.08mm, or customized |

| Color | Silver |

| Width | 3mm–2500mm or as required |

| Thickness Tolerance | ±0.002mm |

| Technique | Cold Rolled / Hot Rolled |

| Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. |

| Applications | Widely used in petroleum, food, chemical, construction, electric power, nuclear, energy, machinery, biotechnology, paper making, shipbuilding, and boiler industries |

Material Comparison

The two most commonly used stainless steels are 304 and 316 (316L).

The key difference lies in the molybdenum (Mo) content — 316L contains Mo, which significantly improves corrosion resistance, especially in high-temperature or chloride environments

316L Advantages Over 304:

Better resistance to pitting and crevice corrosion.

More durable under marine and chemical exposure.

Suitable for high-temperature and corrosive applications.

However, in concentrated sulfuric acid environments, 316L is not recommended, as molybdenum can react with sulfur ions to form sulfides. This illustrates that no stainless steel is completely immune to all forms of corrosion.

Applications

1. Chemical and Petroleum Industry

316L stainless steel foil is widely used in the production of reactors, distillation towers, heat exchangers, and storage tanks due to its outstanding resistance to acids, alkalis, and chloride corrosion.

2. Food Industry

Used in food processing and packaging equipment for its hygienic surface, resistance to contamination, and compliance with food safety standards.

3. Pharmaceutical Industry

Due to its purity and corrosion resistance, 316L foil is commonly used in pharmaceutical manufacturing equipment and drug contact components, ensuring product safety and cleanliness.

4. Electronics and Precision Instruments

Used in battery components, sensor elements, and shielding applications, where thin, durable, and non-reactive materials are essential.

5. Marine Applications

Ideal for seawater environments, ship components, and offshore structures because of its excellent resistance to saltwater corrosion.