-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

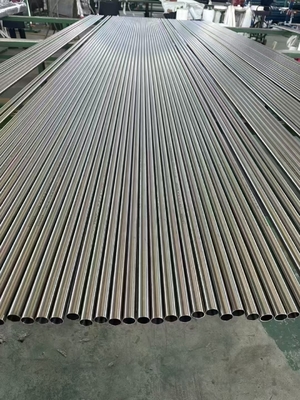

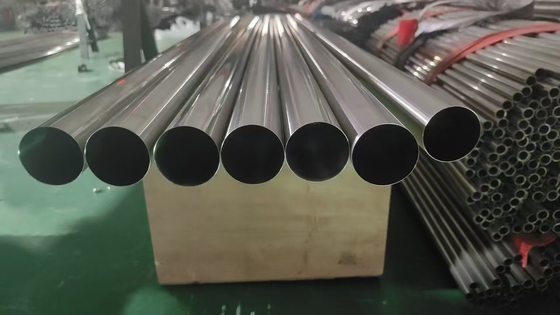

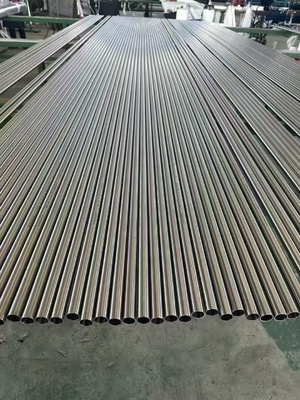

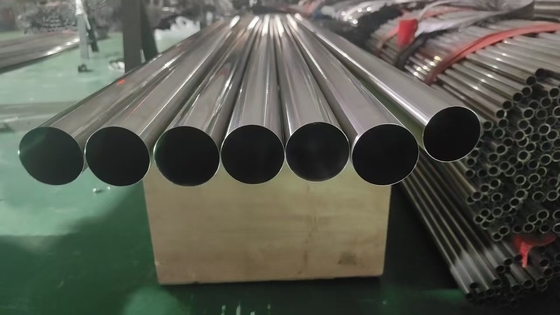

Stainless Steel Products

Stainless Steel Tube 201 304 316 Square Seamless Welding Industry

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTM A312 |

| Minimum Order Quantity | 50kg |

| Price | $6.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Package | Standard Seaworthy Package | Strength | High |

|---|---|---|---|

| Quality Test | MTC(mill Test Certificate) | Processing Business | Decoiling Punching Bending Welding |

| Inspection | Thirdy Inspection Party | Type | Welded |

| Surface | Mill Finished | Easy To Clean | Yes |

| Cost-Effective | Long-term Cost Savings | Alloy Or Not | Is Alloy |

| Available | Custom Processing | Heat Resistance | High |

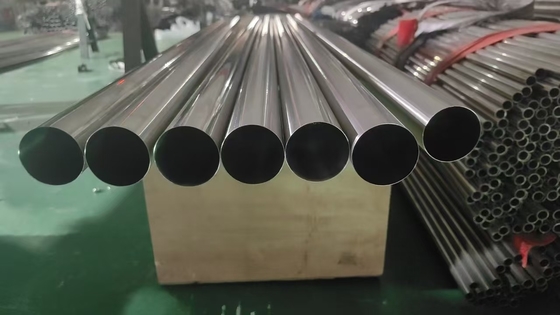

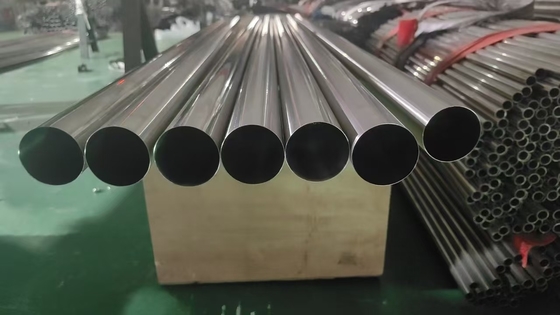

| Diameter | 14 - 1200 Mm | Grade | 200/300/400 Series |

| Wall Thickness | Sch40/ Sch80/sch160) | ||

| Highlight | 316 Stainless Steel Tube,201 Stainless Steel Tube,304 Stainless Steel Tube |

||

Description

Stainless steel pipe is a hollow, long, circular steel product widely used across various industries such as petroleum, chemical, medical, food processing, light industry, mechanical instrumentation, and more.

It serves both as an industrial transportation pipeline and a mechanical structural component due to its combination of strength, corrosion resistance, and lightweight properties.

Because stainless steel pipes maintain equal bending and torsional strength while being lighter than solid materials, they are also popular in the manufacture of mechanical parts, engineering structures, furniture, and kitchenware.

Specification

| Product Name | Stainless Steel Tubes |

|---|---|

| Material | 201, 304, 316, 316L |

| Material Grade | 201 / 202 / 302 / 304 / 304L / 310 / 314 / 314L / 316 / 316L / 430 / 409 / 321 |

| Surface Finish | 400# / 600# / Mirror / 8K |

| Standard | JIS, AISI, ASTM, GB, DIN, EN |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Application | Decorative Tube / Structural & Industrial Use |

Mode of Production

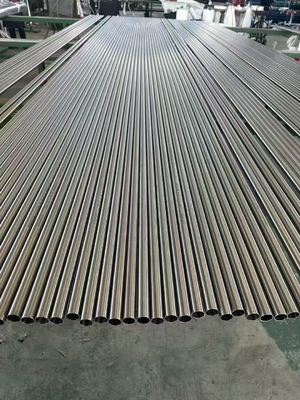

According to production methods, stainless steel pipes are divided into two main categories:

-

Seamless Pipes

Cold drawing and cold rolling are secondary processes used to refine precision and improve surface finish.

Produced through hot rolling, cold rolling, cold drawing, or extrusion, seamless pipes have superior mechanical performance and are ideal for high-pressure or high-temperature applications. -

Welded Pipes

Straight Seam Welded Pipes Spiral Welded Pipes These are widely used in fluid transportation, decoration, and structural applications.

Formed by rolling steel strips and welding the seams, welded pipes can be further divided into:

Applications

-

Industrial Transportation Pipelines

Widely applied in petroleum, chemical, food, and medical industries for fluid and gas transportation. Excellent corrosion resistance ensures durability and stability in harsh environments. -

Mechanical Parts & Engineering Structures

Stainless steel pipes provide equal bending and torsional strength while being lightweight . Ideal for mechanical parts, supports, and frameworks requiring strength and reduced weight. -

Furniture & Kitchenware

Valued for aesthetic appeal and durability, stainless steel pipes are commonly used in furniture, kitchen fittings, and appliances. They enhance product lifespan while maintaining an elegant appearance. -

Defense & Conventional Applications

Utilized in the production of gun barrels, shells, and other precision components, thanks to their strength, heat resistance, and corrosion protection.

Key Features

Excellent corrosion resistance

High strength-to-weight ratio

Good machinability and formability

Long service life and low maintenance

Aesthetic surface finish suitable for decorative uses