-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

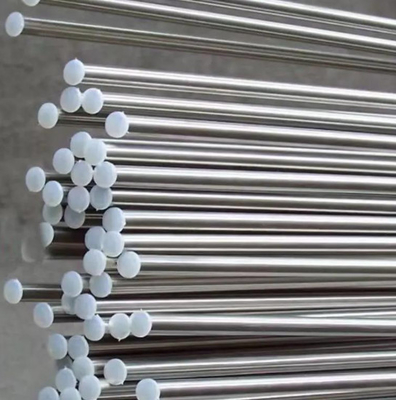

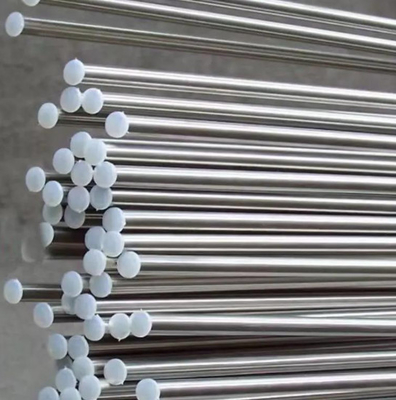

Stainless Steel Products

Stainless Steel Bars 201 304L 316L Machinery Chemical Industry

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASME SA276 |

| Minimum Order Quantity | 50kg |

| Price | $6.00 - $30.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Technology | Cold Rolled.hot Rolled | Quality Test | MTC(mill Test Certificate) |

|---|---|---|---|

| Processing Business | Decoiling Punching Bending Welding | Size | Various Sizes Available |

| Delivery Term | 7~20 Days | Key Word | Steel Cold Rolled Coils |

| Standard | GB | Easy To Clean | Yes |

| Invoicing | By Actual Weight | Tolerance | ±1% |

| Business Type | Manufaturer | Payment | TT Advanced |

| Eco-Friendly | Yes | Longevity | Durable And Long-lasting |

| Section Shape | Round | ||

| Highlight | 316L Stainless Steel Bars,304L Stainless Steel Bars,201 Stainless Steel Bars |

||

Description

Stainless steel bars are metal materials produced from stainless steel ingots through hot rolling, forging, or cold drawing. According to different classification standards, stainless steel bars can be divided into several types, including round bars, square bars, flat bars, hexagonal bars, and octagonal bars.

These bars are widely used in various industrial and commercial applications due to their excellent corrosion resistance, high strength, and aesthetic appearance.

Specification

| Product Name | Stainless Steel Bars |

|---|---|

| Material | 201, 430, 310S, 316, 316L, 304, 1.4462, 2205 |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Surface Finish | No.1 / No.3 / No.4 / HL / 1D / 8K |

| Edge | Trimming |

| Technology | Hot Rolled / Cold Drawn |

| Diameter | 5mm – 250mm |

| Length | 5.8m / 6m / 12m / Customized |

| Tolerance | H8, H9, or as required |

| Application | Machining, Fasteners, CNC Small Parts, Pipe Making |

Production Technology

Stainless steel bars can be manufactured through three primary processes:

-

Hot Rolling: Produces bars with a diameter range of 5.5–250mm. Smaller bars (5.5–25mm) are often supplied in bundles and used for bolts, fasteners, and mechanical components.

-

Forging: Used to produce bars with improved strength and toughness for heavy-duty applications.

-

Cold Drawing: Offers enhanced dimensional accuracy and surface finish, suitable for precision parts.

Application

-

Industrial & Engineering Applications

Stainless steel bars are used across hardware, machinery, petroleum, chemical, shipbuilding, marine engineering, boilers, heat exchangers, aerospace, and new energy equipment industries. Their excellent corrosion resistance and strength make them suitable for complex working environments. -

Food Industry

Commonly used for tableware, kitchen equipment, boilers, and food processing machinery. Grades 304 and 316 are preferred for their corrosion resistance and hygiene properties. -

Chemical Industry

Used in the manufacture of chemical processing equipment, pipes, and heat exchangers. 304 and 316 grades are ideal for handling strong acids, alkalis, and solvents. -

Medical Equipment

Stainless steel bars such as 302 and 304 are used to produce surgical tools and medical instruments due to their non-toxic, corrosion-resistant nature. -

Construction & Decoration

Stainless steel bars, particularly 430 grade, are used for decorative applications and structural components because of their good formability and attractive surface finish.