-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

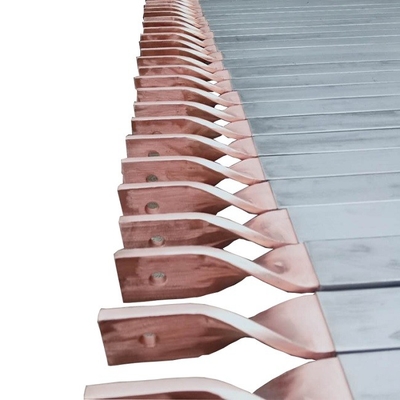

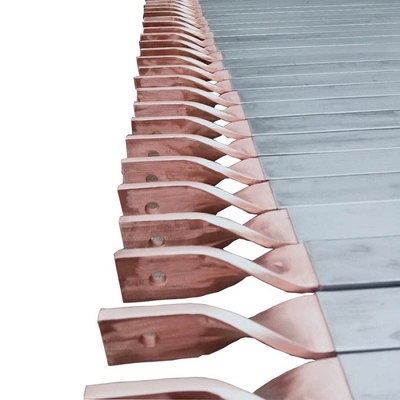

Titanium-Clad Copper Bar Apply For Electrolysis Electroplating

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | GB/T19001-2016/ISO9001:2015 |

| Model Number | ASTM |

| Minimum Order Quantity | 50kg |

| Price | $35.00 - $125.00/ kg |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Highlight | Electroplating Titanium Clad Copper Bar,Electrolysis Copper Bar,Electrolysis Titanium Clad Copper Bar |

||

|---|---|---|---|

Description

Explosion Bonded Titanium Copper Plate is a composite material widely used in industries such as aerospace, defense, power generation, petrochemical, and energy.

It is produced by explosive bonding, a solid-state process in which titanium and copper plates are joined using controlled explosive energy. This process creates a metallurgical bond between the two metals without melting them, ensuring a strong interface and excellent property combination.

The resulting product typically has a titanium outer layer for corrosion resistance and strength, and a copper inner layer for superior electrical and thermal conductivity.

Titanium-clad copper plates, rods, and sheets are ideal for applications requiring high electrical performance, corrosion resistance, and mechanical durability, such as in electrochemical systems, power equipment, and heat exchangers.

Features

-

Excellent electrical and thermal conductivity

-

Outstanding corrosion and abrasion resistance

-

Good weldability and easy machinability

-

Superior heat dissipation performance

-

Excellent anti-oxidation properties and long service life

-

High mechanical strength and dimensional stability even under harsh environments

Advantages

-

Improved Electrical Conductivity – The explosion-bonded interface ensures superior conductivity compared to conventional joining methods.

-

Enhanced Strength – Combines titanium’s structural integrity with copper’s ductility for a durable composite.

-

High Corrosion Resistance – Titanium’s passive oxide layer protects the underlying copper from oxidation and corrosion.

-

Easy Fabrication – Can be easily cut, bent, and formed into custom designs with minimal processing.

-

Cost-Effective Production – Explosion bonding requires less energy and time than welding or diffusion bonding, making it economical for large-scale applications.

Applications

Oil and Gas Industry: Heat exchangers, offshore platforms, and pipeline components

Aerospace and Defence: Electrical connectors, heat sinks, and structural components

Power and Energy: Bus bars, electrodes, and current-carrying parts

Chemical Processing: Reactor linings and anti-corrosive equipment

Electrochemical Systems: Cathodes, anodes, and conductive transition joints

Product Forms

Titanium-Clad Copper Plates / Sheets

Titanium-Clad Copper Square Rods / Bars

Titanium-Copper Transition Joints and Fittings