-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

| Conductivity | Good | Standard | ASTM B338 |

|---|---|---|---|

| Surface Treatment | Polished | Length | <=2000mm |

| Wire Diameter | 0.15-0.20mm Is Commonly Used | Powder Or Not | Not Powder |

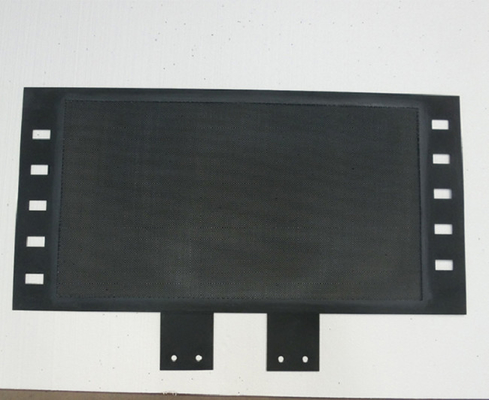

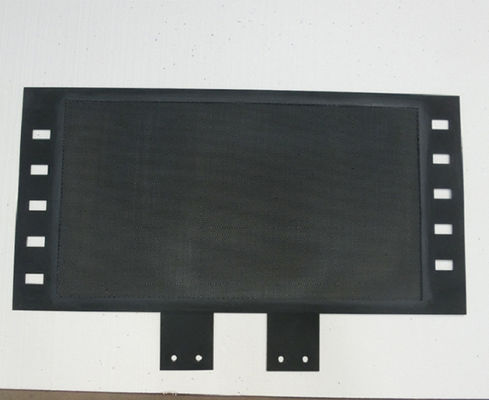

| Composition | Titanium Plate And Titanium Mesh | Operating Life | 8500-20000 Hour |

| Highlight | Polished Surface Titanium Cathode,Electrolysis Titanium Cathode,Electrolysis Cathode |

||

Product Description:

The Titanium Electrode has excellent conductivity, making it ideal for use in environments where electrical resistance is a concern. This product is designed to provide consistent and reliable performance, and it has been tested and certified to meet ASTM B338 standards. The Titanium Electrode is a high-quality product that is designed to meet the needs of various industries, including chemical, petrochemical, and pharmaceutical.

The Titanium Electrode is available in a range of sizes, including a 1.0*50*50mm sample size. This size is perfect for testing and experimentation, and it is ideal for use in research and development. The Titanium Electrode is also available in other sizes, depending on the specific needs of the customer.

The Titanium Electrode is a concentric needle electrode that is designed to provide maximum efficiency and reliability. This electrode is made from high-quality materials, including a 400mm graphite electrode, which ensures that it is strong and durable. The Titanium Electrode is designed to provide consistent and reliable performance, and it has been tested and certified to meet ASTM B338 standards.

In conclusion, the Titanium Electrode is a high-quality product that is designed to meet the needs of various industries. This product has a porosity of 70% to 90%, which ensures that it is highly efficient and effective. The Titanium Electrode is made up of a titanium plate and titanium mesh composition, which gives it exceptional strength and durability. This product is perfect for use in a wide range of applications, including electrochemistry, electroplating, and other related fields. The Titanium Electrode is a concentric needle electrode that is designed to provide maximum efficiency and reliability. This electrode is made from high-quality materials, including a 400mm graphite electrode, which ensures that it is strong and durable. The Titanium Electrode is designed to provide consistent and reliable performance, and it has been tested and certified to meet ASTM B338 standards.

Features:

- Product Name: Titanium Electrode

- Conductivity: Good

- Length: <=2000mm

- Standard: ASTM B338

- Color: Black

- Substrate Material: Pure Titanium GR1

- Compatible with Concentric Needle Electrode

- Compatible with 400mm Graphite Electrode

- Can be used as Electrode Rod of Cobalt & Nickle alloys

Technical Parameters:

| Technical Parameter | Value |

|---|---|

| Porosity | 70%~90% |

| Standard | ASTM B338 |

| Advantages | Lightweight And Strong |

| Surface Treatment | Polished |

| Powder Or Not | Not Powder |

| Conductivity | Good |

| Current | 50mA-100mA |

| Type | Round, Rectangular, Disc Shape And So On |

| Operating Life | 8500-20000 Hour |

| Length | <=2000mm |

Applications:

The Titanium Electrode is widely used in the production of electroplating products. It is an ideal choice for electroplating Cobalt & Nickel alloys, as it has good conductivity and can provide a stable current flow. Its ability to function as a cathodic electrode also makes it suitable for use in the cathodic electrodeposition paint process.

In addition to electroplating, the Titanium Electrode is also used in the medical industry. Its high level of biocompatibility means that it can be used as a Concentric Needle Electrode, which is commonly used in electroencephalography (EEG) and electromyography (EMG) procedures. The Titanium Electrode has also been used in the production of prosthetics due to its biocompatibility and resistance to corrosion.

The Titanium Electrode is also used in the water treatment industry. Its excellent durability and resistance to corrosion make it an ideal choice for use in electrochemical water treatment systems. Its ability to filter and purify liquids makes it a popular choice for use in the production of ultra-pure water, which is used in a variety of industries, including pharmaceuticals, electronics, and semiconductors.

The Titanium Electrode is available in a 1.0*50*50mm sample size, which allows customers to test its performance before making a purchase. Overall, the Titanium Electrode is a versatile product that can be used in a wide range of industries, from electroplating to medical and water treatment. Its excellent composition, color, porosity, and conductivity make it an ideal choice for customers looking for a durable, high-quality electrode.

Customization:

- Wire Diameter: 0.15-0.20mm is commonly used

- Length: <=2000mm

- Porosity: 70%~90%

- Standard: ASTM B338

- Operating Life: 8500-20000 Hour

- Cathodic Electrodeposition Paint: We offer cathodic electrodeposition paint to protect your Titanium Electrode from corrosion and wear and tear.

- Custom Titanium Machining: Our team of experts can assist you in creating a unique design for your Titanium Electrode through our custom titanium machining services.

- 400mm Graphite Electrode: We offer 400mm graphite electrodes to complement your Titanium Electrode and enhance its performance.

Support and Services:

Our Titanium Electrode product comes with comprehensive technical support and services to ensure optimal performance and longevity. Our team of experts is available to assist with installation, troubleshooting, and maintenance of the product. We also offer training sessions to help customers make the most out of their investment. In addition, we provide regular updates and upgrades to the product to ensure it stays up-to-date with the latest industry standards and advancements. Our goal is to provide our customers with the highest level of support and service to ensure their satisfaction and success.