-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

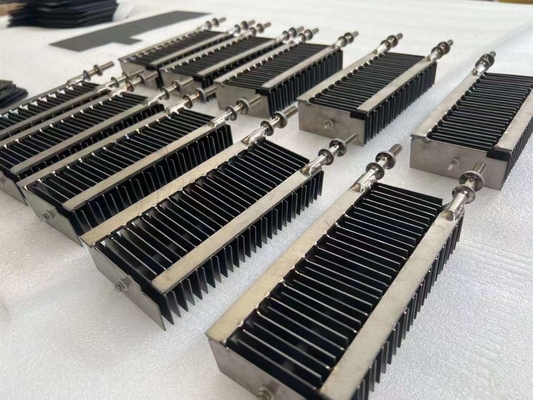

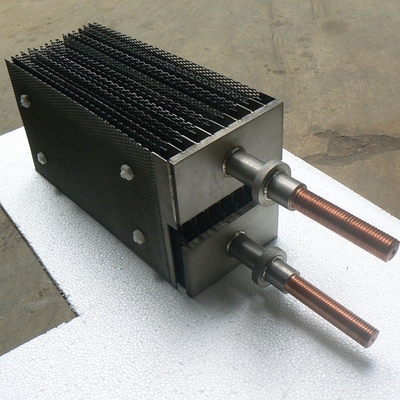

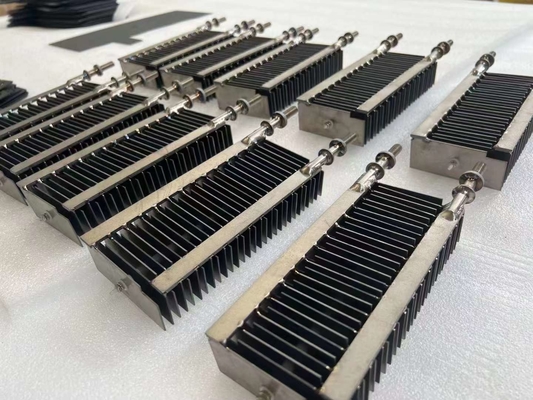

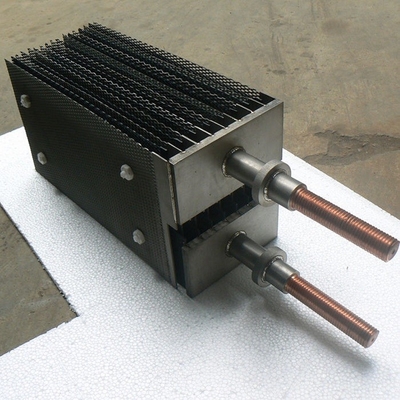

Chlorination Titanium Plate with Ruthenium Oxide Coating in Anealed Supply State

| Place of Origin | CHINA |

|---|---|

| Brand Name | CSTY |

| Certification | ISO9001:2015 |

| Minimum Order Quantity | 10kgs |

| Price | $35.00 - $125.00/ kg |

| Packaging Details | film and wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 5000 Kilogram/Kilograms per Month |

| Electrolysis Cell Type | Membrane Cell | Test Condition | 1mol/L H2SO4 |

|---|---|---|---|

| Product Specifications | Φ3 * 393mm (L) | Temperature | < 80℃ |

| Length | <=2000mm | Supply State | Anealed |

| Another Name | DSE(Dimensionally Stable Electrode | Material | Titanium |

| Coating Thickness | 0.5-1.0 Microns | Operating Life | 8500-20000 Hour |

| Electrode Efficiency | ≥ 90% | Service Time | 1-10years |

| Porosity | 70%~90% | Grade | Titanium And Its Alloy |

| Current | 50mA-100mA | ||

| Highlight | Anealed Supply State Titanium Plate,Chlorination Titanium Plate,Ruthenium Oxide Coating Titanium Plate |

||

Description

Titanium anodes are key components in electrophoretic coating (E-coating) and various electrochemical processes. In electrophoretic coating, the anode attracts negatively charged coating particles suspended in the paint bath, ensuring a uniform and high-quality coating on the substrate. Titanium is an ideal anode material due to its exceptional corrosion resistance, low electrical resistance, high mechanical strength, and long service life. Its cost-effectiveness and durability make it a preferred choice across numerous industries.

Specification

| Product Name | Titanium Anode |

|---|---|

| Material | Gr1 Titanium Plate |

| Regular Sizes | 2×350×L mm, 2×360×L mm, 2×400×L mm (customizable) |

| Shape | Plate, Mesh, Tubular, Bar, Wire |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Coating Material | Iridium Oxide (IrO₂) |

| Coating Weight | Approx. 12 g/m² |

| Coating Area | Single-sided |

| Medium | Paint for Electrophoretic Coating |

| Coating Type | Customizable according to process requirements |

| Operating Temperature | ≤ 32 °C |

| Current Density | ≤ 80 A/m² |

| Guaranteed Operating Life | > 2 years |

| Application | Electrocoating of car bodies, automotive parts, and metal surfaces |

Applications

1. Electrochemical Industry

Electrophoretic Coating (E-Coating): Used in the automobile and metal finishing industries for corrosion-resistant coatings.

Electrolytic Processes: Applied in chlorine, hydrogen, and alkali production for high reaction efficiency and long electrode life.

Battery Manufacturing: Enhances performance and lifespan in electrochemical cells and batteries.

Solar Cells: Used in dye-sensitised solar cells (DSSCs) to improve energy conversion and stability.

2. Chemical Industry

Catalysis: Serves as a high-efficiency, stable catalyst in petroleum, chemical, and pharmaceutical production.

Water Treatment: Used in anion exchange membranes and electrolysis for pollutant removal.

Other Uses: Applicable in wastewater treatment, electroplating, and electrolysis-based processes.

Advantages

-

Excellent corrosion resistance and chemical stability

-

High conductivity and low electrical resistance

-

Uniform coating performance and long service life

-

Lightweight yet strong structure

-

Reusable and low maintenance

-

Environmentally friendly and cost-effective over time