-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

Wholesale Anodized Titanium G23 Body Jewerly Parts For Electrophoretic Coating

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Advantage | Effective.long Working Life. | Working Environment | Coke,Soil And Fresh Water,Seawater |

|---|---|---|---|

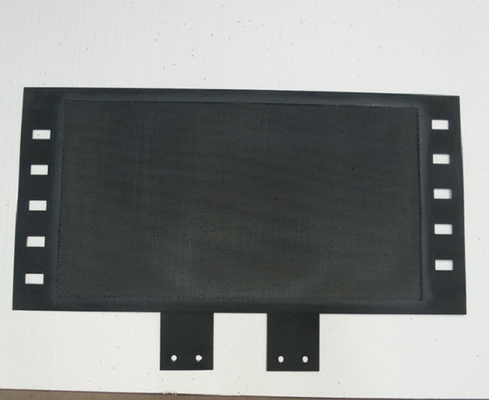

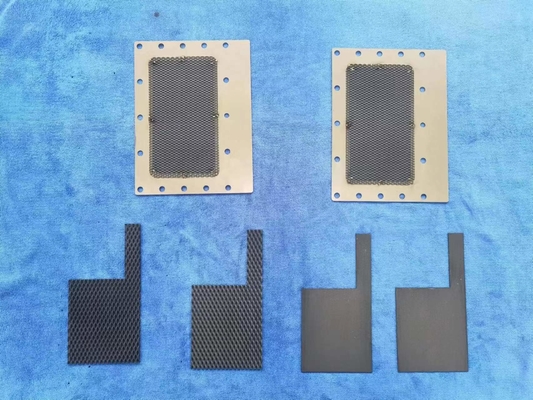

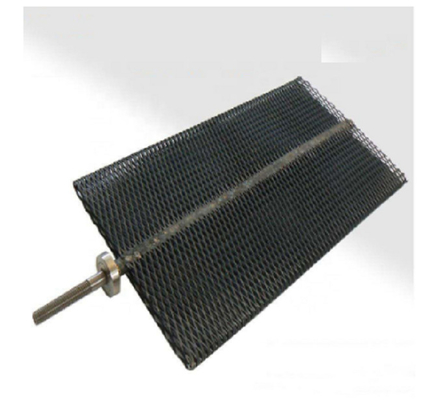

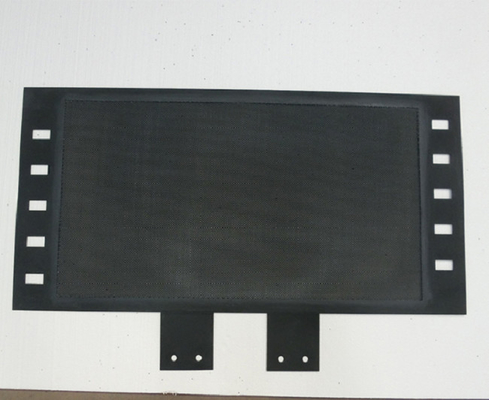

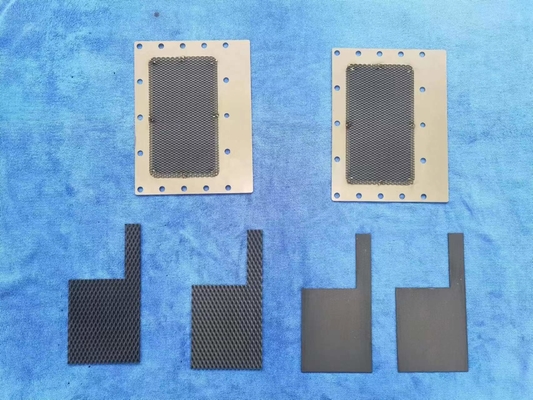

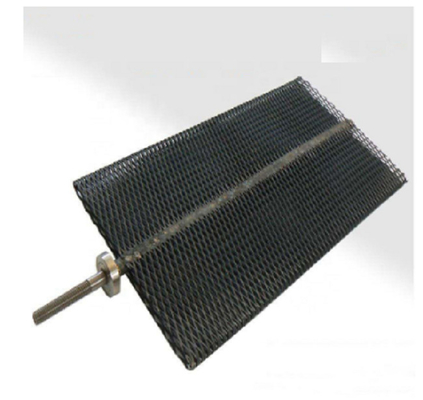

| Purity | 99.9% | Item Name | Titanium Mesh Plate |

| Electrode Type | Anode/Cathode | Substrate Material | Pure Titanium GR1 |

| Current | 50mA-100mA | Powder Or Not | Not Powder |

| Opening | Diamond Openings | Service Life | 1-10years |

| Conductivity | Good | Application | Electrolysis |

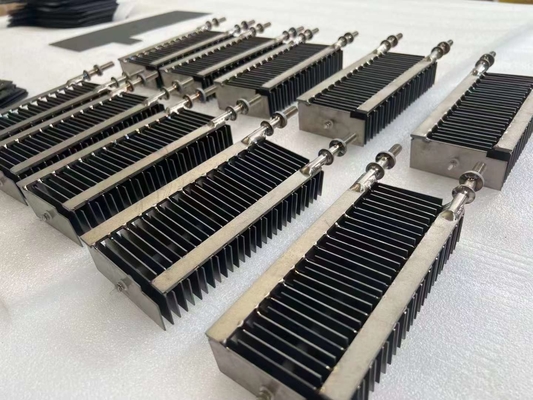

| Shape | Plate Mesh Tubular Bar Wire | Size | Customizable |

| Mesh Size | 60-80 Is Typically Used | ||

| Highlight | Electrophoretic Coating Body Jewerly Parts,Anodized Titanium Jewerly Parts,Titanium G23 Body Jewerly Parts |

||

Description

Titanium anodes are widely used in electrophoretic coating (E-coating) and other electrochemical processes. In electrophoretic coating, the anode attracts negatively charged paint particles suspended in the coating solution, allowing them to deposit evenly on the substrate surface.

Titanium is an ideal material for anodes due to its excellent corrosion resistance, low electrical resistance, and cost-effectiveness. The use of titanium extends the service life of anodes and ensures stable performance in demanding electrochemical environments.

Specifications

| Item | Details |

|---|---|

| Product Name | Titanium Anode |

| Material | Gr1 Titanium Plate |

| Regular Sizes | 2×350×L mm, 2×360×L mm, 2×400×L mm |

| Shape Options | Plate, Mesh, Tubular, Bar, Wire |

| Processing Services | Bending, Welding, Decoiling, Cutting, Punching |

| Coating Material | Iridium Oxide (IrO₂) |

| Coating Weight | Approx. 12 g/m² |

| Coating Area | Single-sided |

| Medium | Electrophoretic Paint |

| Coating Type | Customized |

| Operating Temperature | ≤ 32°C |

| Current Density | ≤ 80 A/m² |

| Service Life (Guaranteed) | > 2 years |

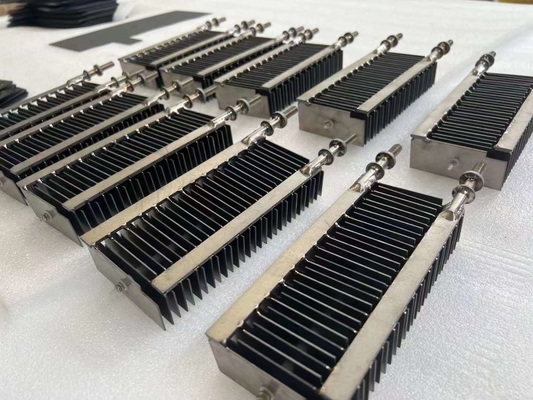

| Application | Electrophoretic coating of car bodies and components |

Applications

1. Electrochemical Industry

Electrolysis: Used in chlorine, alkali, and hydrogen production for efficient reactions and long service life.

Battery Manufacturing: Improves stability and lifespan of batteries.

Solar Cells: Key material in dye-sensitised solar cells to enhance energy conversion efficiency and stability.

2. Chemical Industry

Catalyst: Serves as a high-efficiency, stable catalyst in the petroleum, chemical, and pharmaceutical industries.

Anion Exchange Membrane: Helps remove harmful substances in wastewater treatment through effective ion exchange processes.

Key Features

Excellent corrosion resistance

Long service life and stable performance

Customizable coating types and configurations

Suitable for electrophoretic and electrolytic applications

Environmentally friendly and cost-effective