-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

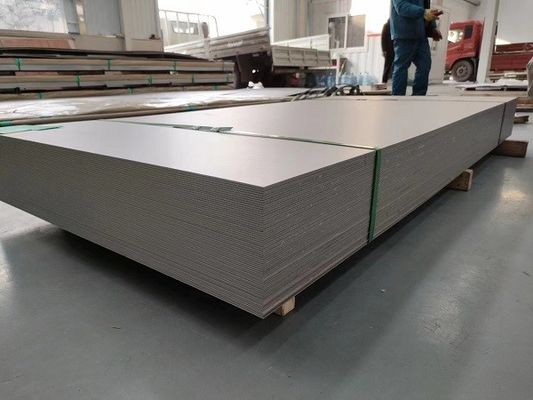

Titanium Gr5 Coiled Sheet Titanium Alloy Plate Hardness 360HV Medical

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | TITANIUM ALLOY | Grade | Grade 5 |

|---|---|---|---|

| Thickness | 0.6-50mm | Length | 6000mm Max |

| Width | 3000mm Max | Surface | Bright, Pickling |

| Standard | ASTM B265 | Hardness | 360HV Max |

| Highlight | 360HV Titanium Alloy Plate,Gr5 Titanium Coiled Sheet,Pickling Titanium Coiled Sheet |

||

Description

Titanium Gr5 coiled sheet, also known as Ti-6Al-4V or UNS R56400, is an alpha-beta titanium alloy and the most widely used of all titanium grades.

This alloy contains approximately 6% aluminum and 4% vanadium, providing an excellent balance of strength, corrosion resistance, and weldability.

Titanium Gr5 coiled sheet is heat-treatable and exhibits an exceptional strength-to-weight ratio, making it ideal for applications where both lightweight performance and durability are critical.

It is used extensively across aerospace, medical, marine, and industrial fields, as well as in 3D printing and sporting equipment manufacturing.

Physical Properties

| Grade | Tensile Strength (MPa, Min) | Yield Strength (MPa, Min) | Elongation (% Min) |

|---|---|---|---|

| Gr1 | 240 | 170 | 24 |

| Gr2 | 345 | 275 | 20 |

| Gr3 | 450 | 380 | 18 |

| Gr4 | 550 | 483 | 15 |

| Gr5 | 895 | 828 | 10 |

| Gr7 | 400 | 275 | 18 |

| Gr9 | 620 | 483 | 15 |

| Gr12 | 483 | 348 | 18 |

| Gr23 / Gr5-ELI | 793 | 759 | 10 |

Chemical Composition

| Grade | Fe (max) | O (max) | N (max) | C (max) | H (max) | Pd (max) | Al (%) | V (%) | Ni (max) | Mo (max) | Ti |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gr1 | 0.20 | 0.18 | 0.03 | 0.08 | 0.015 | - | - | - | - | - | Balance |

| Gr2 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | - | - | - | - | - | Balance |

| Gr3 | 0.30 | 0.35 | 0.05 | 0.08 | 0.015 | - | - | - | - | - | Balance |

| Gr4 | 0.50 | 0.40 | 0.05 | 0.08 | 0.015 | - | - | - | - | - | Balance |

| Gr5 (Ti-6Al-4V) | 0.40 | 0.20 | 0.05 | 0.08 | 0.015 | - | 5.5–6.7 | 3.5–4.5 | - | - | Balance |

| Gr7 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | 0.12–0.25 | - | - | - | - | Balance |

| Gr9 | 0.25 | 0.15 | 0.03 | 0.08 | 0.015 | - | 2.5–3.5 | 2.0–3.0 | - | - | Balance |

| Gr12 | 0.30 | 0.25 | 0.03 | 0.08 | 0.015 | - | 0.6–0.9 | 0.2–0.4 | - | - | Balance |

| Gr23 / Gr5-ELI | 0.25 | 0.03 | 0.03 | 0.08 | 0.0125 | - | 5.5–6.5 | 3.5–4.5 | - | - | Balance |

Key Features

High strength-to-weight ratio

Excellent corrosion resistance in seawater and chemical environments

Heat treatable for enhanced mechanical performance

Good weldability and formability

Biocompatible, suitable for medical implants

Hardness: ~360 HV

Applications

-

Aerospace Industry – Aircraft frames, turbine components, and engine parts.

-

Medical Industry – Implants, bone plates, and surgical instruments due to excellent biocompatibility.

-

Marine Industry – Propeller shafts, hulls, and decks due to corrosion resistance in seawater.

-

Automotive Industry – High-performance parts and exhaust systems for reduced weight and improved strength.

-

Chemical Processing – Reactor vessels and heat exchangers requiring corrosion and pressure resistance.

-

3D Printing – Widely used in additive manufacturing for high-performance parts.

-

Military and Defense – Armor plating, missile casings, and aircraft frames.

-

Architectural and Decorative Uses – Cladding and window frames for lightweight, corrosion-resistant structures.