-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

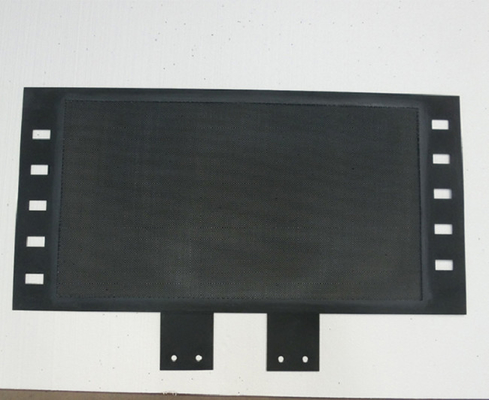

MMO Titanium Anodes Iridium-Tantalum Coating Mixed Metal Oxide Electrode

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | mixed metal oxides-Iridium,Tantalum |

| Minimum Order Quantity | 1 Piece |

| Price | $26.00 - $58.00/ Piece |

| Packaging Details | 1. Packing with moisture-proof paper; 2. Packing with foam plastics in all sides; 3. Packing products in standard wooden cases. |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 10000 Piece/Pieces per Month |

| Brand Name | Changsheng Titanium Anode | Substrate | Titanium Gr1 Gr2 |

|---|---|---|---|

| Coating | Mixed Metal Oxides Of Iridium,Tantalum | Shape | Plates, Meshes, Rods, Or Custom-designed |

| Coating Thickness | Typically In The Range Of 5~20 Microns,depending On The Application And Manufacturer | Current Density | Typically Between 10~300 A/m²,depends On The Application, Electrolyte Composition, And Desired Electrochemical Reaction |

| Highlight | Gr1 MMO Titanium Anodes,Iridium Tantalum Coating Metal Oxide Electrode,Electroplating MMO Titanium Anodes |

||

Description of MMO Titanium Anode Iridium-Tantalum Coated

MMO (Mixed-Metal Oxide) titanium anode with iridium-tantalum coating is specialized electrochemical electrode used in various applications where high-performance and durability are required. Here's a description of MMO titanium anode with iridium-tantalum coating:

1.Base Material: Titanium Grade 1 or Grade 2 is commonly used, known for its excellent corrosion resistance, mechanical strength, and compatibility with various electrolytes.

2.Mixed-Metal Oxide Coating: The iridium-tantalum coating, a type of MMO coating, is applied to the titanium base material. This coating consists of mixture of iridium oxide and tantalum oxide, which enhances the anode's electrochemical performance and corrosion resistance.

3.Electrochemical Properties: The iridium-tantalum coating on the MMO titanium anode improves the anode's electrochemical properties, including increased catalytic activity and current-carrying capacity. This promotes efficient electrochemical reactions and enhances overall performance.

4.Corrosion Resistance: The iridium-tantalum coating provides excellent corrosion resistance, protecting the underlying titanium substrate from degradation even in harsh and corrosive environments. This corrosion resistance is especially important in applications involving chloride-rich or acidic electrolytes.

5.High Current Efficiency: The combination of the titanium base material and the iridium-tantalum coating allows for high current efficiency during electrochemical processes. This means a larger portion of the applied electrical current is effectively utilized for the desired electrochemical reactions, resulting in improved efficiency and reduced energy consumption.

6.Longevity and Durability: The MMO titanium anode with an iridium-tantalum coating exhibits excellent durability and a long service life. The coating's superior corrosion resistance and stability ensure that the anode can withstand challenging operating conditions and provide consistent performance over an extended period.

7.Application Versatility: MMO titanium anodes with an iridium-tantalum coating are utilized in various electrochemical applications, including electroplating, wastewater treatment, electrolytic synthesis, and other processes where durability and high performance are essential.

Specification of MMO Titanium Anode Iridium-Tantalum Coated

Specifications of MMO (Mixed-Metal Oxide) titanium anodes with an iridium-tantalum coating can vary depending on the specific application and manufacturer. However, here are some common specifications:

| Base Material | Titanium (Grades 1 or 2) |

| Coating Composition |

Iridium-Tantalum Coating: Consists of a combination of iridium oxide (IrO2) and tantalum oxide (Ta2O5). The specific composition and ratio may vary depending on the desired electrochemical performance and application requirements. |

| Coating Thickness |

Typically in the range of 5 ~ 20 microns depending on the application and manufacturer. Thicker coatings provide better durability and extended service life. |

| Current Density |

typically between 10~300 A/m². The recommended current density depends on the application, electrolyte composition, and desired electrochemical reaction |

| Connection Type | threaded studs, bolt holes, or welded tabs, to facilitate easy and secure installation |

| Dimensions and Shape |

plates, meshes, rods, or custom-designed geometries depending on the application requirements. The dimensions are typically specified based on the size and configuration of the electrolytic cell or system. |

Iridium-Tantalum coating (Ir-Ta)

![]()

Advantages of Iridium-Tantalum Titanium anode

Iridium-tantalum titanium anodes offer several advantages in various electrochemical applications. Here are some key advantages:

1. Corrosion Resistance: Iridium-tantalum coating provides exceptional corrosion resistance, even in highly corrosive environments such as chloride-rich solutions or acidic electrolytes. This allows the anode to maintain its integrity and performance over an extended period, reducing the need for frequent replacements.

2. High Stability: The iridium-tantalum coating ensures excellent stability during electrochemical reactions, even at high current densities and temperatures. This stability prevents degradation and ensures consistent and reliable performance of the anode.

3. Efficient Electrochemical Reactions: The iridium-tantalum coating enhances the anode's electrochemical properties, including its catalytic activity and current-carrying capacity. This improves the efficiency of electrochemical reactions, resulting in higher conversion rates, reduced energy consumption, and improved process efficiency.

4. Long Service Life: The combination of titanium base material and iridium-tantalum coating contributes to the anode's durability and longevity. It can withstand harsh operating conditions and maintain its performance over a prolonged period, reducing the frequency of replacements and associated costs.

5. Versatile Applications: Iridium-tantalum titanium anodes are suitable for a wide range of electrochemical applications. They are commonly used in industries such as electroplating, water treatment, electrolytic synthesis, and cathodic protection. The anodes can be customized in various shapes and sizes to suit specific application requirements.

6. Wide Operating Range: Iridium-tantalum titanium anodes can operate efficiently over a wide range of operating conditions, including different electrolytes, temperatures, and pH levels. This versatility makes them suitable for various applications across different industries.

7. Low Maintenance: The corrosion resistance and stability of iridium-tantalum titanium anodes minimize the need for frequent maintenance. They require less cleaning and have a reduced risk of degradation or fouling, resulting in lower maintenance costs and downtime.

8. Environmental Compatibility: Iridium and tantalum are precious metals that are relatively inert and non-toxic. This makes iridium-tantalum titanium anodes environmentally friendly and suitable for applications where compliance with environmental regulations is essential.

Overall, the advantages of iridium-tantalum titanium anodes, such as corrosion resistance, stability, efficiency, and long service life, make them a preferred choice in various electrochemical applications.

Application areas of Iridium-Tantalum Titanium anode:

Iridium-tantalum titanium anodes find applications in various electrochemical processes where their unique properties and advantages are beneficial. Here are some application cases where iridium-tantalum titanium anodes are commonly used:

1. Electroplating: Iridium-tantalum titanium anodes are widely utilized in electroplating processes, where a layer of metal is deposited onto a substrate. They are particularly suitable for plating applications that involve high current densities, aggressive electrolytes, or require precise control of the plating thickness and quality. The anodes' corrosion resistance and stability ensure consistent plating performance and long-lasting operation.

2. Water Treatment: In water treatment applications, iridium-tantalum titanium anodes are used in electrochemical processes such as electrocoagulation, electrooxidation, and electrochlorination. They help remove pollutants, disinfect water, and treat wastewater. The anodes' corrosion resistance and efficient electrochemical reactions contribute to effective water treatment and purification.

3. Electrowinning: Electrowinning is a process used to extract metals from their ores or concentrates. Iridium-tantalum titanium anodes are employed in electrowinning cells to facilitate the deposition of metals onto the cathode. The anodes' stability, corrosion resistance, and high current-carrying capacity enable efficient electrowinning processes, resulting in increased metal recovery rates and reduced energy consumption.

4. Chlor-Alkali Production: In the chlor-alkali industry, iridium-tantalum titanium anodes play a crucial role in the electrolysis of brine (sodium chloride solution) to produce chlorine, caustic soda (sodium hydroxide), and hydrogen gas. The anodes' corrosion resistance and durability make them suitable for operating in the highly corrosive electrolyte, ensuring efficient and reliable production of chlor-alkali products.

5. Electrolytic Synthesis: Iridium-tantalum titanium anodes are utilized in various electrolytic synthesis processes, including the production of chemicals, organic compounds, and specialty materials. These anodes offer high catalytic activity and stability, enabling precise control over the desired chemical reactions, yielding high-quality products.

6. Cathodic Protection: In cathodic protection systems, iridium-tantalum titanium anodes are employed to protect metallic structures, such as pipelines, offshore platforms, and ship hulls, from corrosion. The anodes generate a protective current that counteracts the corrosive reactions on the protected structures, extending their service life and reducing maintenance costs.

7. Semiconductor Manufacturing: Iridium-tantalum titanium anodes are utilized in various electrochemical processes within the semiconductor industry, such as electroplating of metal films, etching, and cleaning of semiconductor surfaces. The anodes' stability and precise control over the electrochemical reactions contribute to the fabrication of high-quality semiconductor devices.

These are just a few examples of the application cases where iridium-tantalum titanium anodes are used. Their corrosion resistance, stability, efficiency, and versatility make them suitable for a wide range of electrochemical processes across different industries.

Tag: MMO Titanium Electrode and anodes, mmo anode; titanium anode