-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

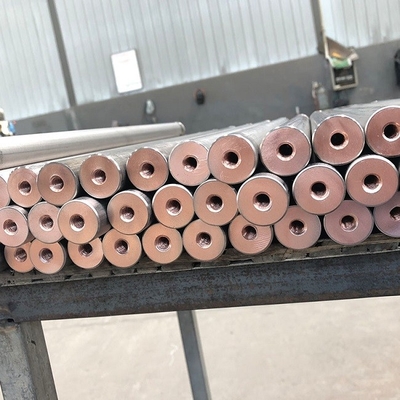

Explosion Bonded Titanium Copper Plate Titanium Clad Copper Square Rod

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Titanium And Copper | Thickness | 10-50mm |

|---|---|---|---|

| Width | 500-1000mm | Techincal | Explosion Bonded |

| Titanium Thickness | 1-5mm | Length | 100mm - 6000mm |

| Surface Treatment | Polished, Sandblasted, Or Customized | Samples | 12mm X 52mm X L |

| Technical | Forging, Rolling And Explosion Welded | Advantage | Acid Resistance High Performance |

| Application | Electronics, Chemical Industry, Aerospace, Etc. | Titanium Layer | 0.8-3mm |

| Copper | OFHC | Standards | GB/T12769 2 |

| Technique | Explosion And Hot Rolled | Shape | Round Rod, Square Rod |

| Diameter | 3.0~85mm | Grade | Titanium Copper |

| Test | Ultrasonic Test(UT) ; X-ray Test | ||

| Highlight | Explosion Bonded Titanium Copper Plate,Titanium Clad Copper Square Rod,Titanium Clad Copper Plate |

||

Description

Explosion Bonded Titanium Copper Plates are advanced composite materials created through an explosive bonding process that fuses two different metals — titanium and copper — into a single, high-performance structure.

This process produces a titanium-clad copper plate or rod, featuring a titanium outer layer for superior corrosion resistance and strength, and a copper inner layer for excellent electrical and thermal conductivity.

These titanium-copper composites are widely used in aerospace, defence, energy, and chemical industries, as well as in oil and gas pipelines, electrical conductors, and mechanical components requiring durability under high temperature and pressure.

Titanium-clad copper plates are also known for their ease of installation — they require no additional welding or machining, saving both time and cost.

Features

-

Excellent Conductivity and Resistance:

Outstanding electrical and thermal conductivity, with excellent abrasion and corrosion resistance. -

Good Processability:

Easy to weld, cut, and form, offering flexibility in fabrication and installation. -

Superior Heat Dissipation:

Effective in high-temperature environments where efficient heat transfer is critical. -

High Oxidation Resistance:

Titanium’s anti-oxidation properties ensure a long service life even in harsh conditions. -

High Strength and Low Cost:

Titanium-clad copper combines mechanical strength with cost efficiency, providing a reliable yet economical solution. -

Wear Resistance:

Excellent wear performance, suitable for demanding industrial applications.

Advantages

-

Enhanced Electrical Conductivity

Explosion bonding ensures a seamless metallurgical bond, resulting in superior electrical conductivity compared with conventional bimetal rods or welded joints. -

Increased Strength

The combination of titanium and copper provides exceptional mechanical strength, surpassing that of either metal alone. -

Outstanding Corrosion Resistance

The titanium outer layer effectively protects the copper core from corrosion, oxidation, and chemical attack, even in extreme environments. -

Ease of Fabrication

Explosion-bonded titanium copper plates are easy to cut, shape, and machine into custom configurations without losing bonding strength. -

Cost-Effectiveness

Compared with traditional welding or casting methods, explosion bonding offers lower energy consumption and reduced processing costs, making it a practical and efficient choice for large-scale applications.

Applications

Explosion Bonded Titanium Copper Plates and Rods are used across multiple industries, including:

Aerospace and Defence:

Structural components, electrical connectors, and high-performance conductors.

Energy and Power:

Conductive transition joints, current-carrying bars, and power generation systems.

Oil & Gas Industry:

Components in high-pressure, high-temperature pipelines and refining systems.

Chemical and Marine Engineering:

Equipment exposed to corrosive media, including heat exchangers, condensers, and reactor vessels.

Electrochemical and Plating Industry:

Cathode and anode materials in electrolytic plating, chlor-alkali production, and electrolysis systems.

Key Benefits

Strong metallurgical bonding between titanium and copper

Lightweight yet highly durable

High current-carrying efficiency

Resistance to corrosion and chemical erosion

Reduced maintenance and longer service life

Product Forms Available

Titanium-Clad Copper Plates

Titanium-Clad Copper Sheets

Titanium-Clad Copper Square Rods

Titanium-Clad Copper Bars