-

Titanium Pipe Fittings

-

Titanium Welded Pipe

-

Titanium Pipe Flange

-

Seamless Titanium Tubing

-

Titanium Heat Exchanger

-

Titanium Coil Tubing

-

Titanium Alloy Sheet

-

Titanium Fasteners

-

Titanium Welding Wire

-

Titanium Round Bar

-

Titanium Forgings

-

Titanium Clad Copper

-

Titanium Electrode

-

Metal Sputtering Target

-

Zirconium Products

-

Sintered Porous Filter

-

Shape Memory Nitinol Wire

-

Niobium Products

-

Tungsten Products

-

Molybdenum Products

-

Tantalum Products

-

Equipment Products

-

Aluminum Products

-

Stainless Steel Products

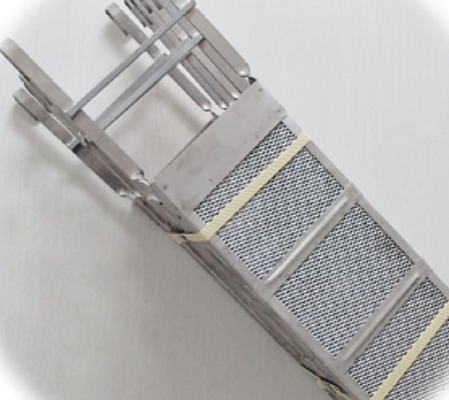

Titanium Anode Baskets Mmo Coating 6mm X 3mm 10mm X 5mm For Electroplating

| Place of Origin | China |

|---|---|

| Brand Name | CSTI |

| Certification | ISO9001 |

| Model Number | titanium anode baskets20221216 |

| Minimum Order Quantity | 1 Piece |

| Price | $100.00 - $300.00/ Piece |

| Packaging Details | 1. Packing with moisture-proof paper; 2. Packing with foam plastics in all sides; 3. Packing products in standard wooden cases. |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T, L/C |

| Supply Ability | 1000 Piece/Pieces per Month |

| Substrate | Gr1 /Gr2 As Basement | Composition | Titanium Plate And Titanium Mesh |

|---|---|---|---|

| Coating | Ir Oxide /Pt Oxide | Type | Round, Rectangular, Disc Shape And So On |

| Thickness Of Titanium Ranges | 0.5-2mm | Mesh Size | 6mm×3mm, 10mm×3mm, 10mm×5mm,16mm×8mm, 25mm×15mm And So On |

| Highlight | Mmo Coating Titanium Anode Baskets,Electroplating Titanium Anode Baskets,Gr1 Titanium Basket |

||

titanium anode baskets Gr1 Ir Pt coating metal plating,revovery

titanium anode baskets for electroplating and insoluble anode are essential parts of electroplating tank. Most anode baskets are made of titanium materials with excellent corrosion resistance. The insoluble anodes used for electroplating are usually titanium substrates and coated with a layer of MMO noble metal oxides such as iridium tantalum and other functional coatings on the surface of the substrate.

titanium anode baskets for electroplating has the following characteristics:

1, the shape and size is stable, so that the current distribution is uniform, maintain the uniformity of electroplating.

2, the delivery package is customized, so as to ensure the quality of the product, avoid the poor electrode in the plating process damage and corrosion, so that the production line to stop cleaning and replacing the anode, so as to improve production efficiency.

3. After special process and formula, the precious metal coating has high activity, which makes the regeneration of electroplating additives play a strong catalytic role.

4, the use of titanium substrate material, anode service life is long, and can withstand higher current density. Because the titanium anode is an insoluble anode, it will not dissolve itself, so it will not produce anode mud and other impurities metal ions leakage pollution tank.

| Composition | titanium plate and titanium mesh |

| thickness of titanium ranges | between 0.5-2mm |

| mesh size | 6mm×3mm, 10mm×3mm, 10mm×5mm,16mm×8mm, 25mm×15mm and so on |

| types of titanium basket |

round, rectangular, disc shape and so on Special design can also be made according to the requirements of the product |

Titanium baskets are usually used in conjunction with anode bags. Anode bag is generally made of acid and alkali corrosion resistant or oxidation resistant polyester (polyester fiber) or polypropylene (polypropylene fiber), set outside the titanium basket, to prevent the anode mud slag and other debris mixed into the tank. Sometimes, in order to prevent anode mud more effectively and prevent the coating from burring, a double anode bag can be used. When using double bag, the inner bag should be set tightly and the outer bag should be loosened. The anode bag must have the characteristics of good corrosion resistance, good wear resistance and good elasticity

Product Show

Our trade show

Nearly 30% of order determinded by visti our factory or visit our foreign booths . our customer from Canada ,south korea, Russia,Germany ......All of the world .The hanover industrial Fair in Germany every year .We meet many customers at our booth.

Titanium basket design points

1. The conductivity of titanium is poor. Generally, the hook current outside the water is not more than 0.24A/mm2, and the hook current in the water is not more than 1.5A/mm2

2, titanium basket hook and electrode generally do not use plane or round surface contact, this way is easy to cause poor contact, so that the electrode will produce spot corrosion

Precautions for use titanium anode baskets

1. The titanium anode basket and anode bag are soaked in 10% lye for 6-8 hours, washed dry, and then soaked in 5% dilute sulfuric acid

2. When it is found that the titanium basket hook becomes obviously hot, the number of titanium basket or the cross-section size of titanium basket hook can be increased to improve the conductivity of titanium basket

3. The mouth of the titanium basket should be slightly higher than the liquid level by 30-40mm to prevent the outflow of anode slag

4. The lower end of the titanium basket should be 100~150mm higher than the parts (the side close to the liquid level can be considered to install a mask), in order to avoid the current concentration of the lower part, causing burning

5, the titanium basket and the anode should be in close contact, otherwise the anode potential on the titanium basket will rise sharply, so that the surface of the titanium basket oxygen evolution and chlorine evolution reaction, causing damage to the titanium basket and the oxidation of additives

6, the anode bag to the titanium basket mouth tightly wrapped, the bottom of the bag should be set aside a few centimeters gap, in order to store the possible anode mud slag

7, every half a month to a month to clean the anode bag and titanium anode basket, and replace the damaged anode bag, to ensure that the plating solution, plating tank pollution

8, timely supplement or enrich the anode material, so as to avoid insufficient nickel "overhead", otherwise titanium will be eroded

Tag:titanium anode baskets,titanium anode baskets for electroplating,titanium anode basket